A method of mixing and matching explosives in the field for burning and destroying

A technology of mixing and matching explosives, applied in the direction of blasting, etc., can solve the problems of destruction accidents, detonation, combustion and destruction, etc., and achieve the effect of good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

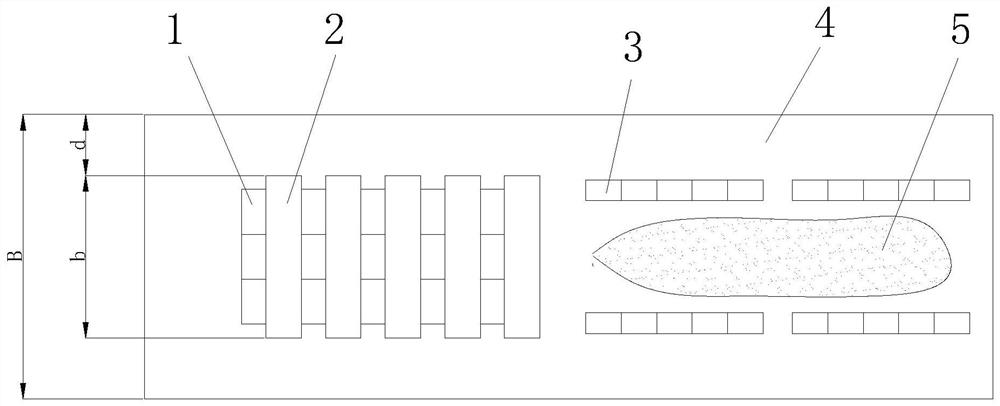

[0018] Such as figure 1 Shown, a kind of multi-explosives mixes and matches the field burning destruction method, comprises the following steps:

[0019] (1) Select a shooting range for burning, the site is flat and open and slightly higher than the surrounding terrain, the ventilation conditions are good, there are no protection targets such as houses within 300 meters around the site, the fire zone is more than 50 meters away from the vegetation, and there are no shrubs and weeds in the site , considering the emergency needs, one fire engine and eight foam fire extinguishers are equipped on site;

[0020] (2) Lay wood on the site, and lay a variety of explosives on the wood. A variety of explosives include black ladder explosives, emulsion explosives, tai explosives, and scale TNT. Black ladder explosives and emulsion explosives are strip structures. Black ladder ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com