Method for weakening light attenuation of polycrystalline silicon solar cell

A technology for solar cells and solar cells, applied in the field of photovoltaic solar energy, can solve the problems of complex production process, lowering the maximum sintering temperature and cooling rate, complex equipment and operation process, etc., and achieve the effect of simple operation process and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Place the PERC polysilicon solar cell on the heater, heat the heater to 175°C, then apply a forward voltage of 1V to the polysilicon solar cell for 10 minutes, and then take the polysilicon solar cell out of the heater.

[0018] (2) Heat the heater to 400°C, place the polycrystalline silicon solar cell on the heater again, apply a reverse voltage of 0.3V to the polycrystalline silicon solar cell, and process for 1 minute, then take the polycrystalline silicon solar cell out of the heater.

[0019] The control sample is a PERC polysilicon solar cell without any treatment.

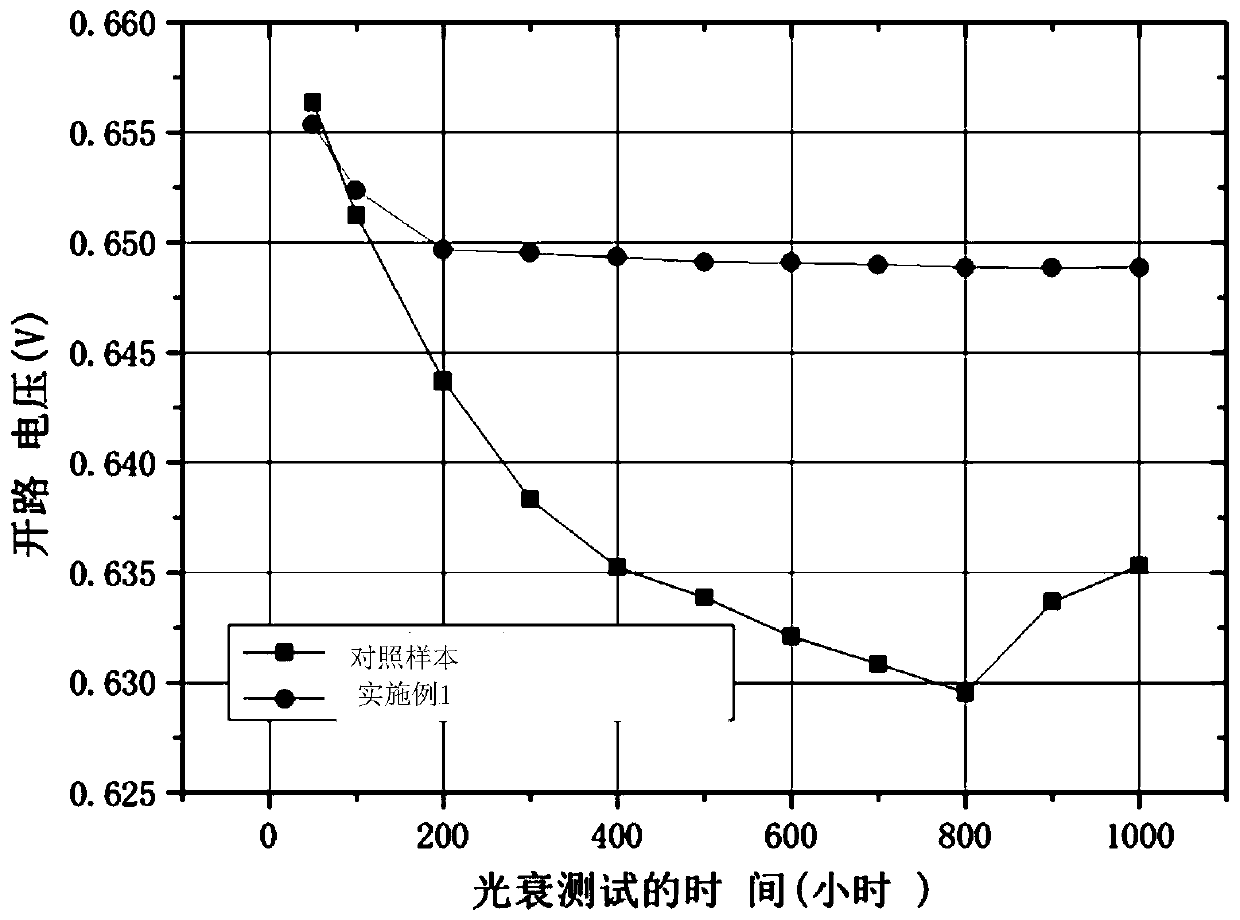

[0020] figure 1 It is the voltage change situation of the light decay of the untreated polysilicon PERC solar cell after the treatment of Example 1 and the control sample;

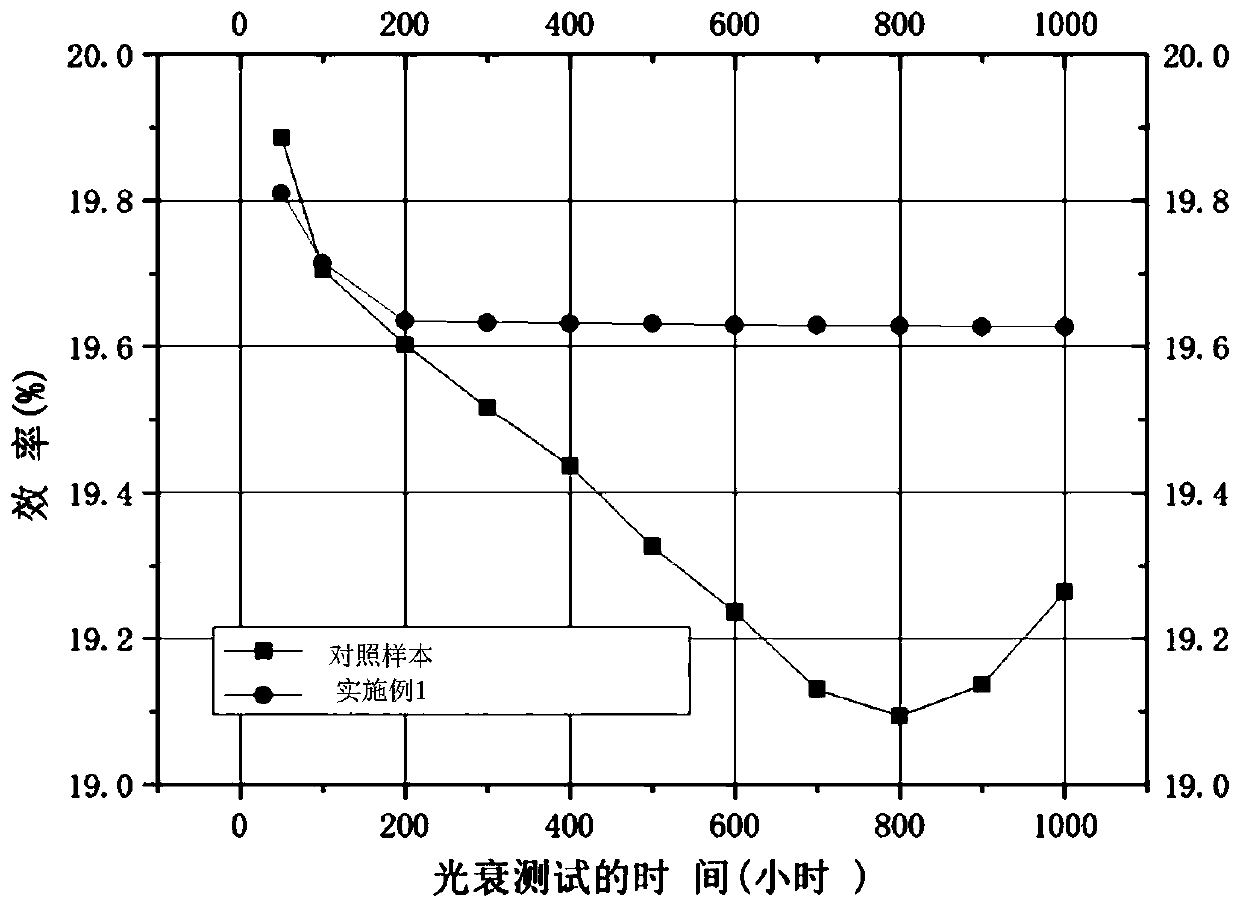

[0021] figure 2 It is the variation of light decay efficiency of polysilicon PERC solar cells treated in Example 1 and untreated polysilicon PERC solar cells in the control sample.

Embodiment 2

[0023] Others are the same as in Embodiment 1, the applied forward voltages are respectively 2V and 4V, which can reduce the degree of light attenuation to less than 1.5% and less than 1% respectively.

Embodiment 3

[0025] Others are the same as in Example 1. In step 1, the heaters are heated to 150° C. and 250° C. respectively, both of which can reduce the degree of light attenuation to below 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com