External rotor flywheel pulse synchronous generator system

A pulse synchronous, permanent magnet synchronous motor technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of long shafting, low system power density and reliability, etc., and achieve short shafting, light weight, The effect of high rotor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

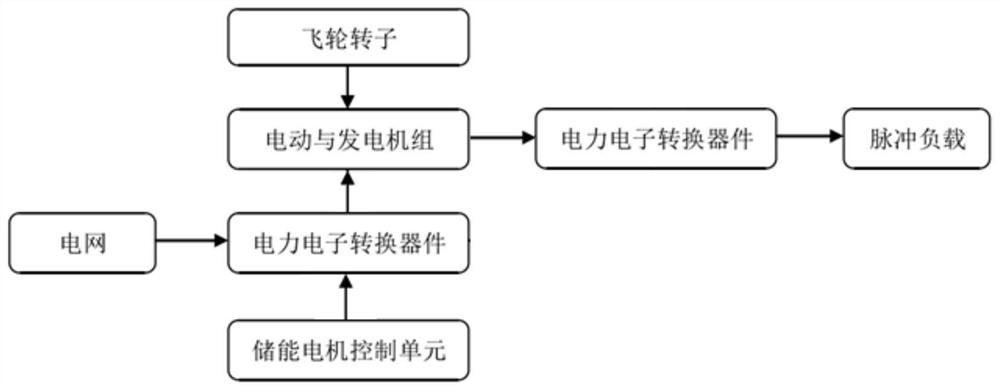

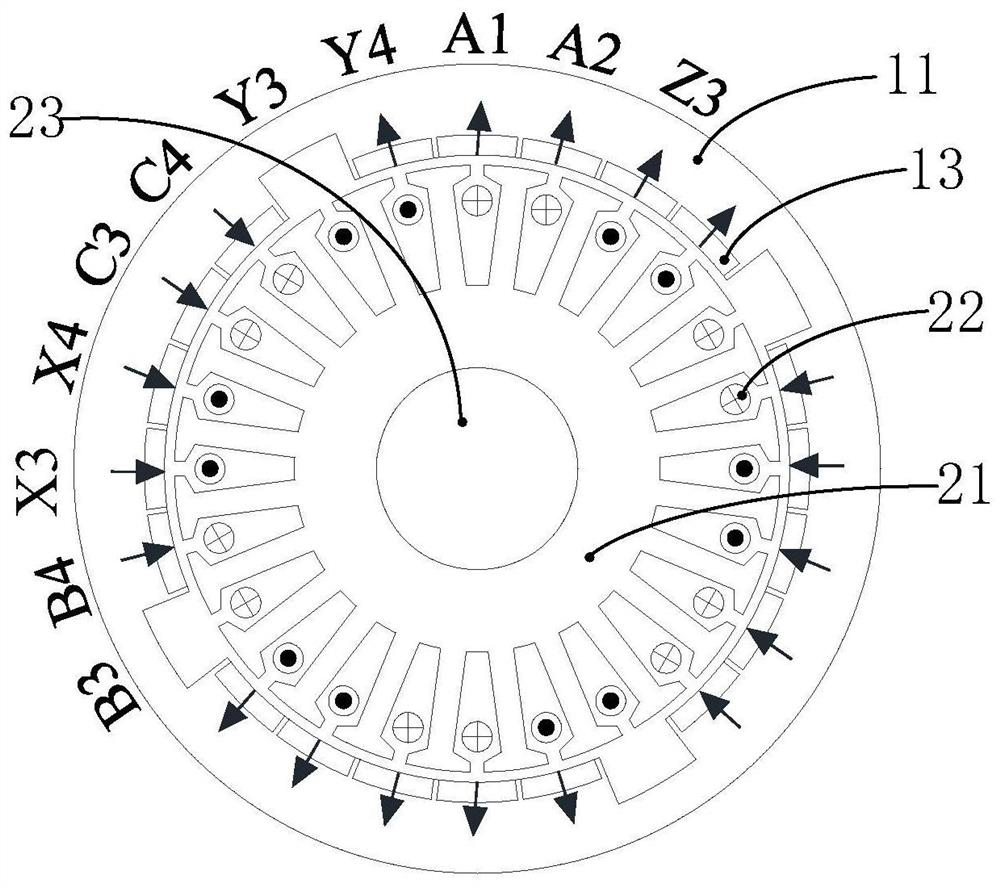

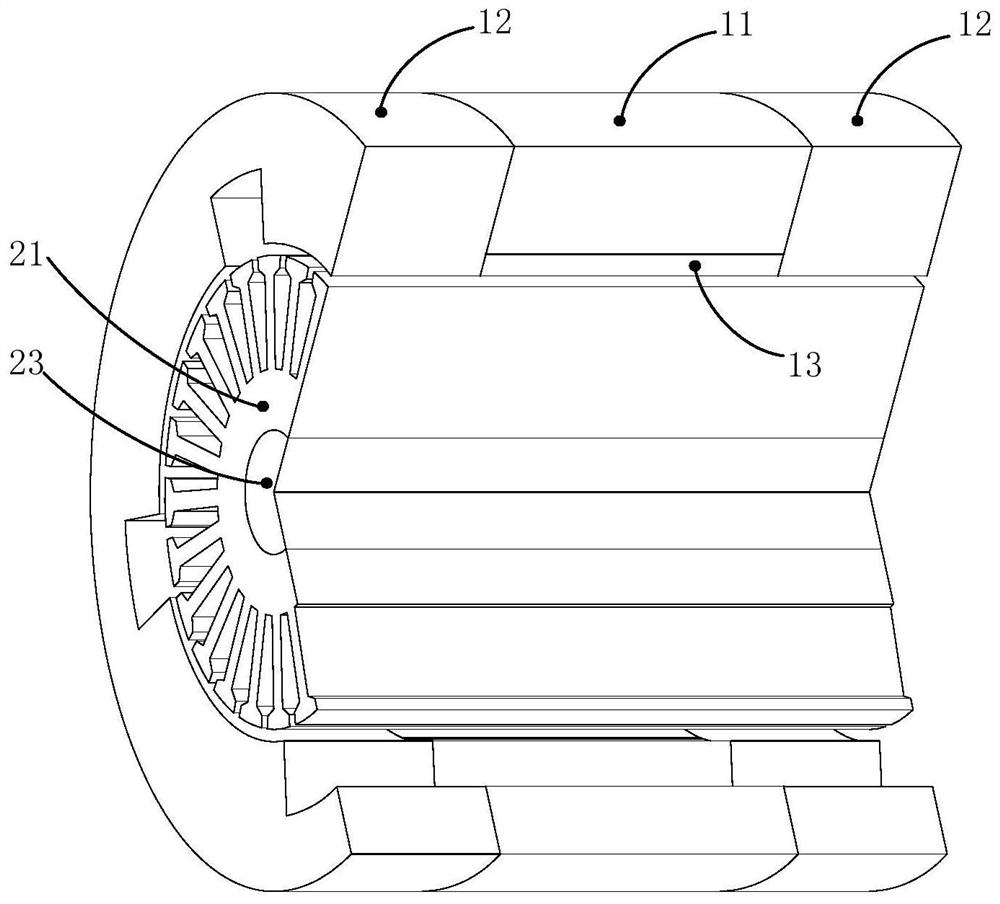

[0056] Embodiment 1: as Figure 2 to Figure 5 As shown, the outer rotor flywheel pulse synchronous generator system of this embodiment includes an input inverter, an input motor, an outer rotor permanent magnet synchronous motor, an output rectifier, an excitation current adjustment unit and an inertial flywheel;

[0057] The output end of the input inverter is connected to the lead-out line of the input motor, the rotor of the input motor is coaxially connected to the rotor of the outer rotor permanent magnet synchronous motor, the output end of the armature winding of the outer rotor permanent magnet synchronous motor is connected to the AC input end of the output rectifier connection; the output end of the armature winding of the outer rotor permanent magnet synchronous motor is connected to the excitation current adjustment unit; the rotor of the outer rotor permanent magnet synchronous motor is coaxially connected with the inertial flywheel.

[0058] The outer rotor flywh...

Embodiment 2

[0077] Embodiment 2: as Figure 2-6 As shown, the outer rotor flywheel pulse synchronous generator system of this embodiment includes an input inverter, an outer rotor permanent magnet synchronous motor, an output rectifier, an excitation current adjustment unit and an inertial flywheel; there are three sets of outer rotor permanent magnet synchronous motor stators Multi-phase armature windings, one of which is the input power winding, such as Image 6 As shown, two sets of output power windings, the output end of the input inverter is connected to the lead-out wire of the input power winding of the outer rotor permanent magnet synchronous motor rotor, the phase difference between the two sets of output power windings is 30 degrees electrical angle, each set The output ends of the output power windings are connected to an excitation current adjustment unit, and the lead-out wires of each set of output power windings are connected to the AC input end of an output rectifier, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com