Thread winding roller cleaning and storing device

A technology of storage device and winding roller, which is applied in the field of spinning machinery, can solve the problems of reducing work efficiency, occupying a large area, increasing manual operation, etc., and achieves the effect of simple structure, good sealing performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

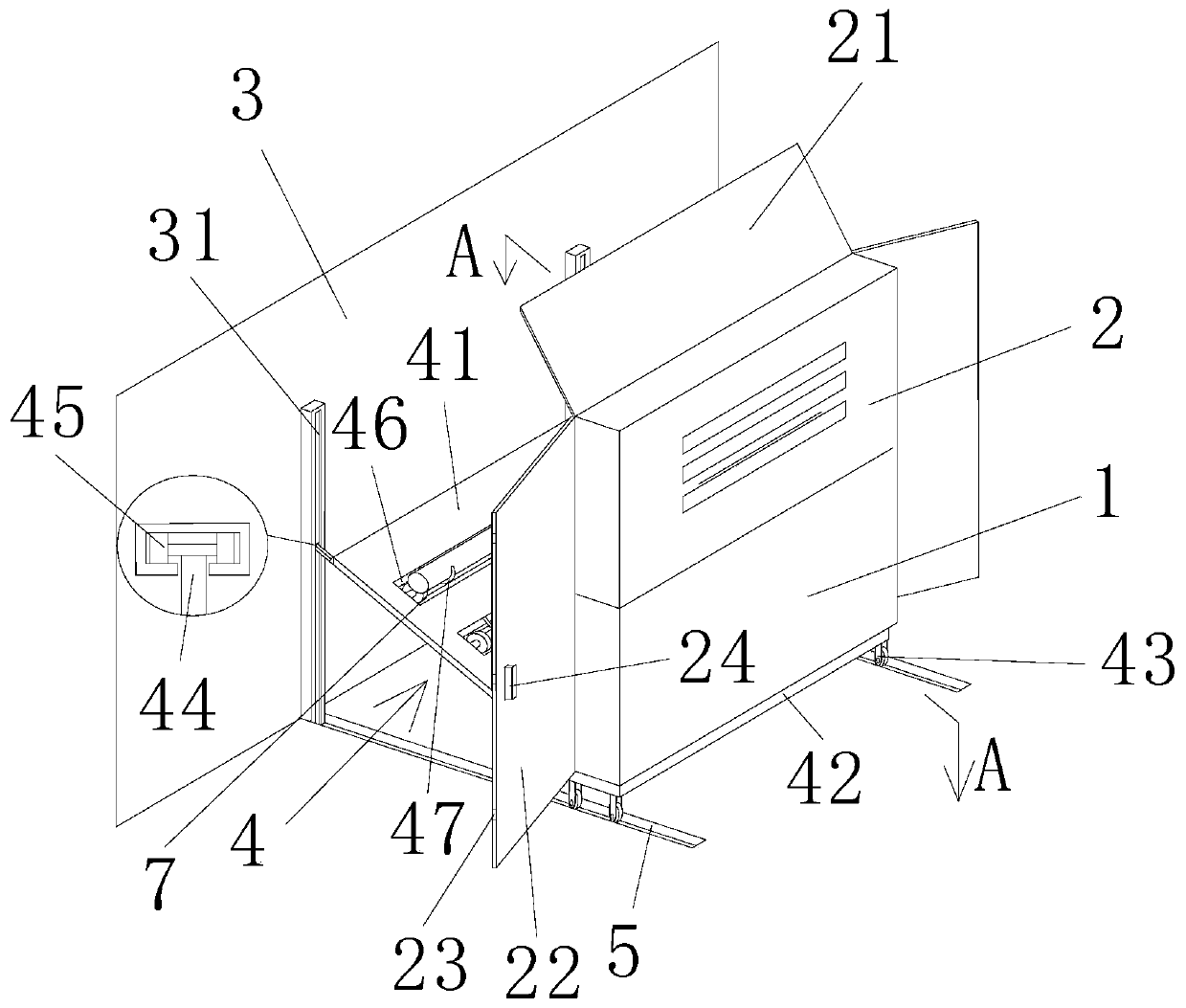

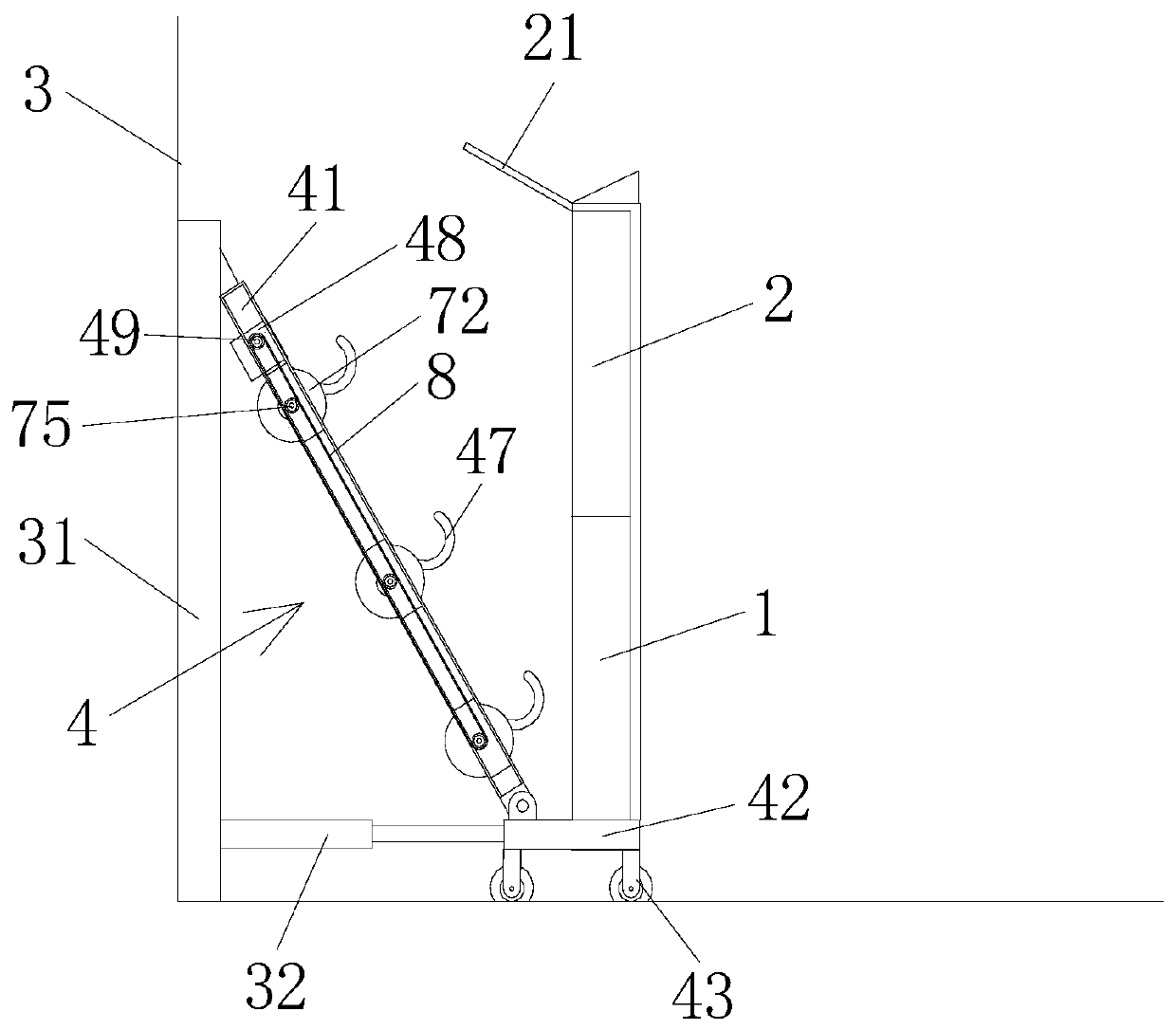

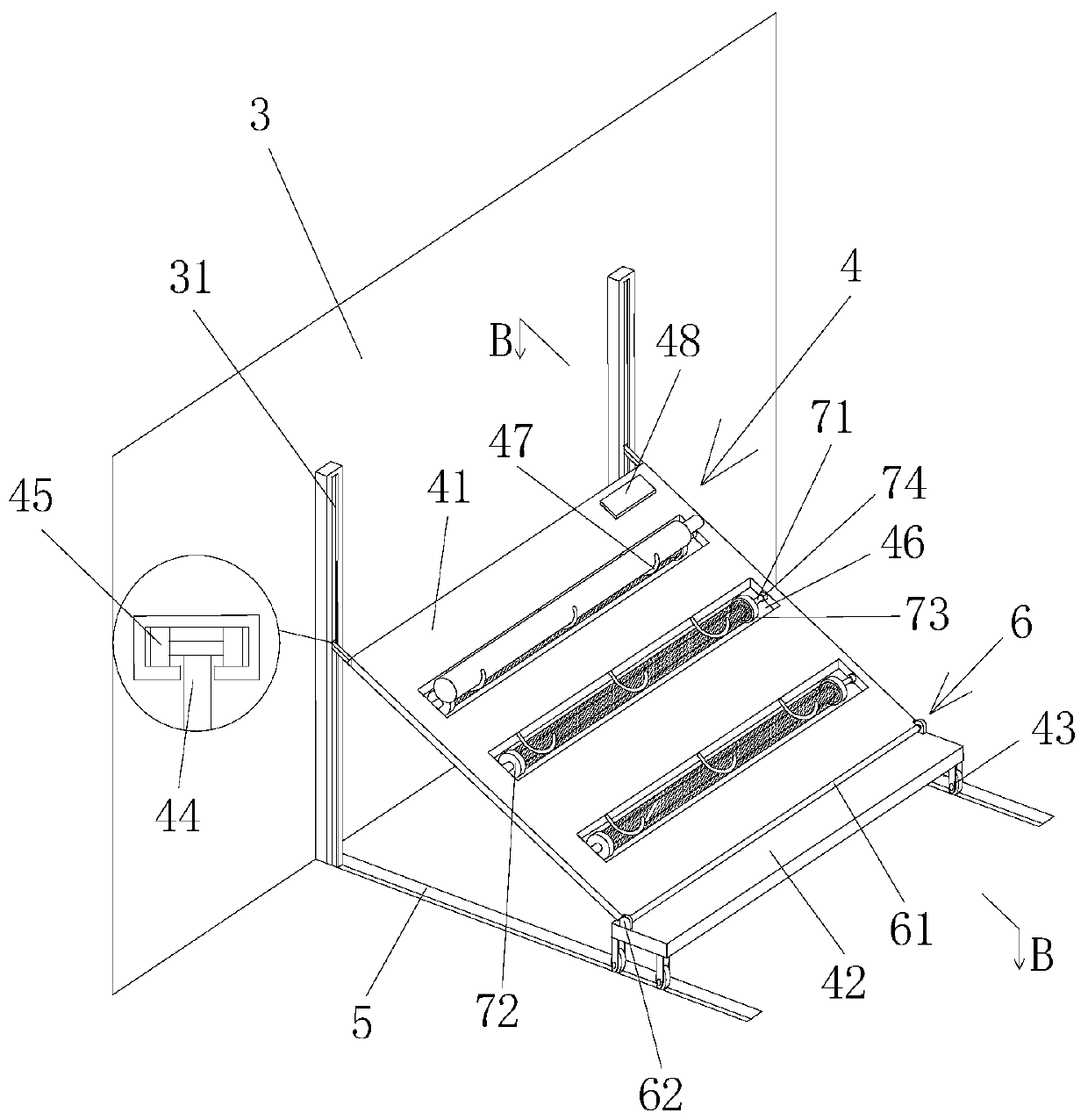

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] see Figure 1 to Figure 6 As shown, the present invention provides an embodiment: a wire winding roller cleaning and storage device, a vacuum cleaner 1 for dedusting the wire winding roller and a dryer 2 for drying and dehumidifying, including a wall 3 and a ground The wire winding roller storage rack 4 between, two guide rail grooves 5 are provided on the described ground, the trapezoidal guide rail 31 corresponding to the position of the guide rail groove 5 is provided on the described wall surface 3, the trapezoidal guide rail 31 The bottom end is embedded in the guide rail groove 5; the wire winding roller storage rack 4 includes a storage plate 41 and a bottom plate 42, and first guide wheels 43 are arranged around the bottom of the bottom plate 42, and the first guide wheels 43 are embedded in the In the guide rail groove 5, the first guide wheel 43 moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com