Multifunctional integration device capable of riveting conical cabin section

An integrated device and multi-functional technology, applied in the field of multi-functional integrated devices, to meet the improvement requirements of standard operations, facilitate production organization and management, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

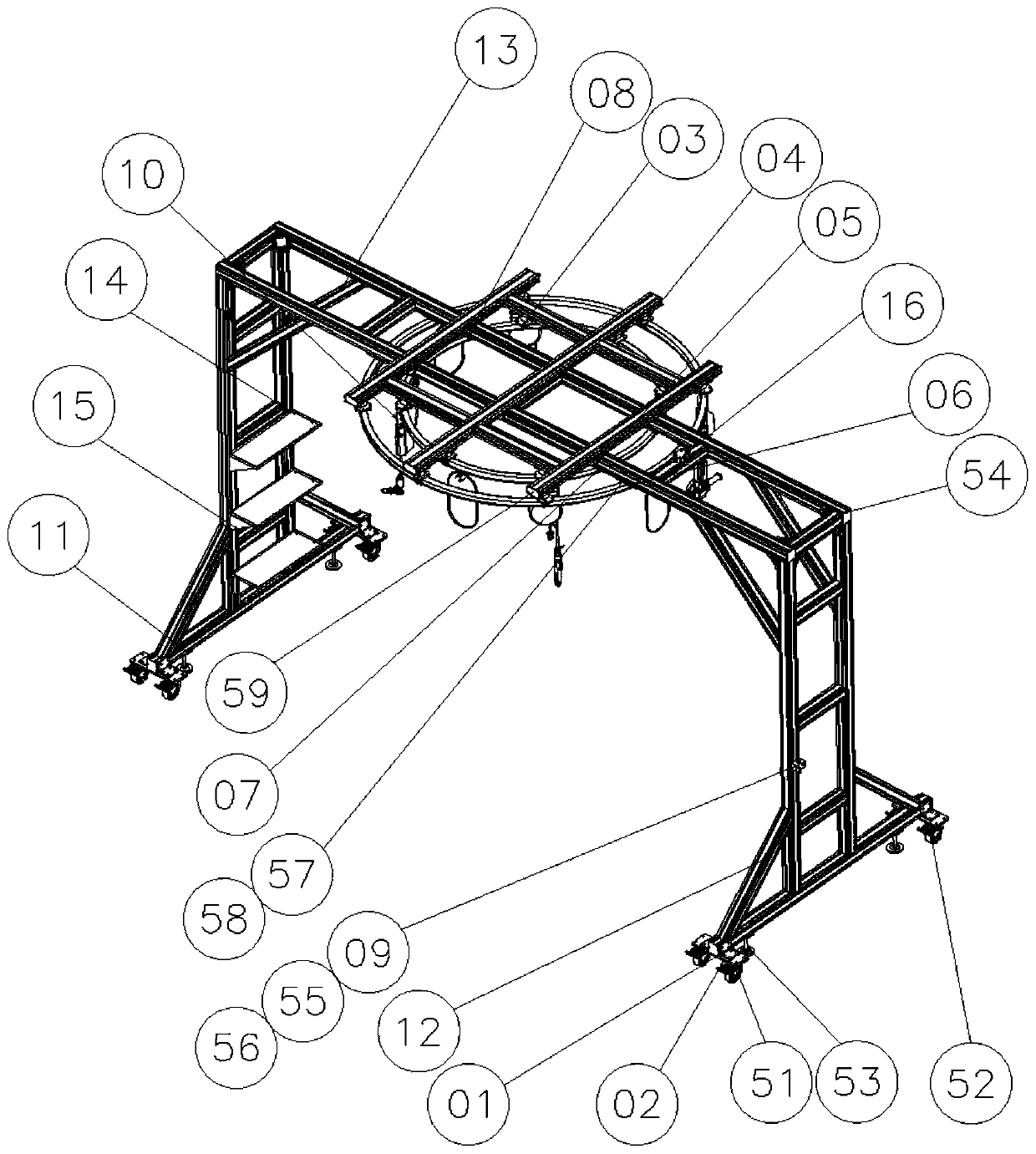

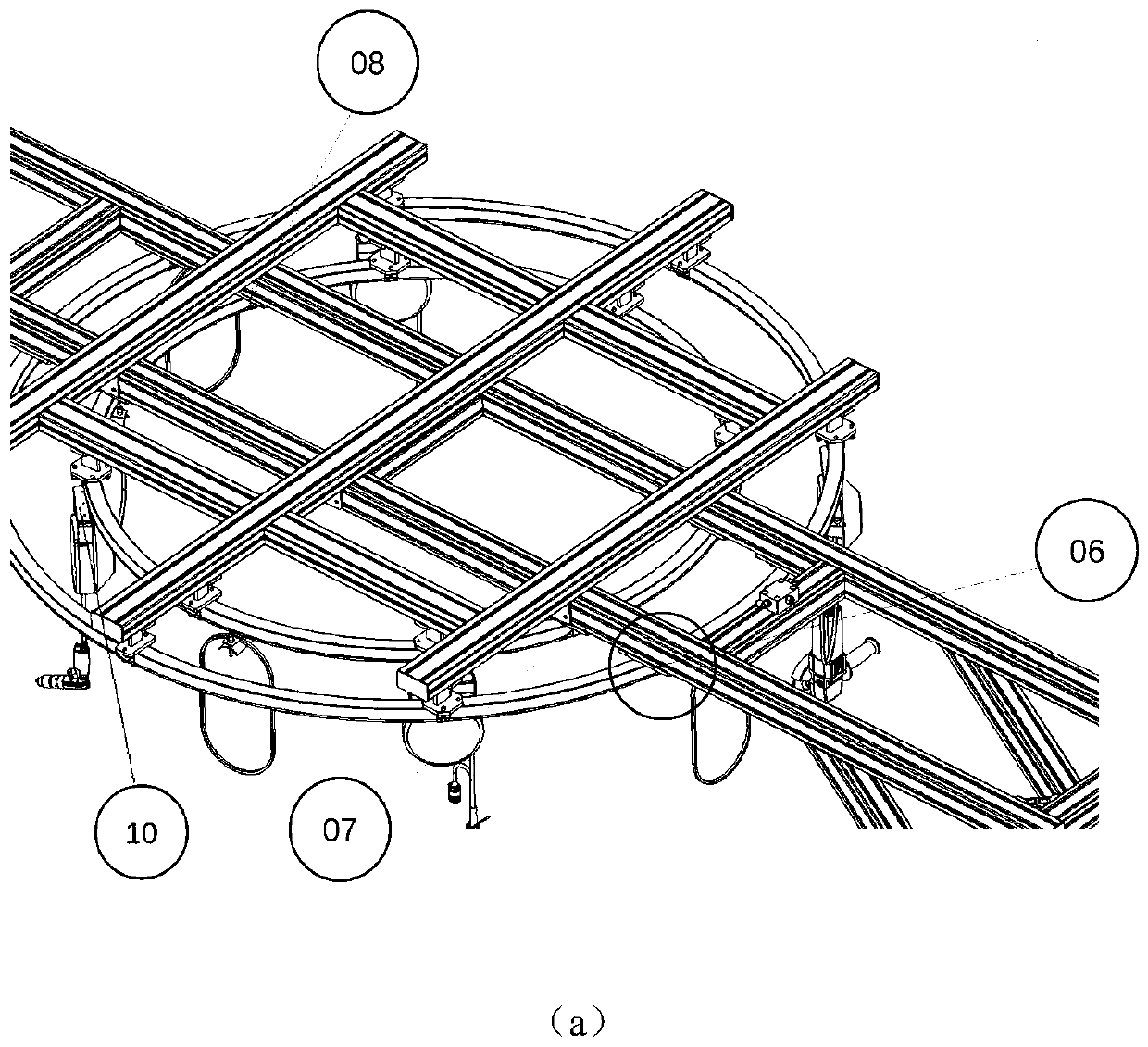

[0032] Such as Figure 1 to Figure 9 As shown, the multifunctional integrated device for riveting the conical cabin section of this embodiment includes a П-shaped gimbal, inner and outer ring guide rails, a balancer and a semi-automatic riveting tool. The inner and outer ring guide rails are suspended on the top of the П-shaped gimbal. The balancer and the inner and outer ring guide rails are connected, and the balancer and the semi-automatic riveting tool can move or hover within 180° along the track of the inner and outer ring guide rails.

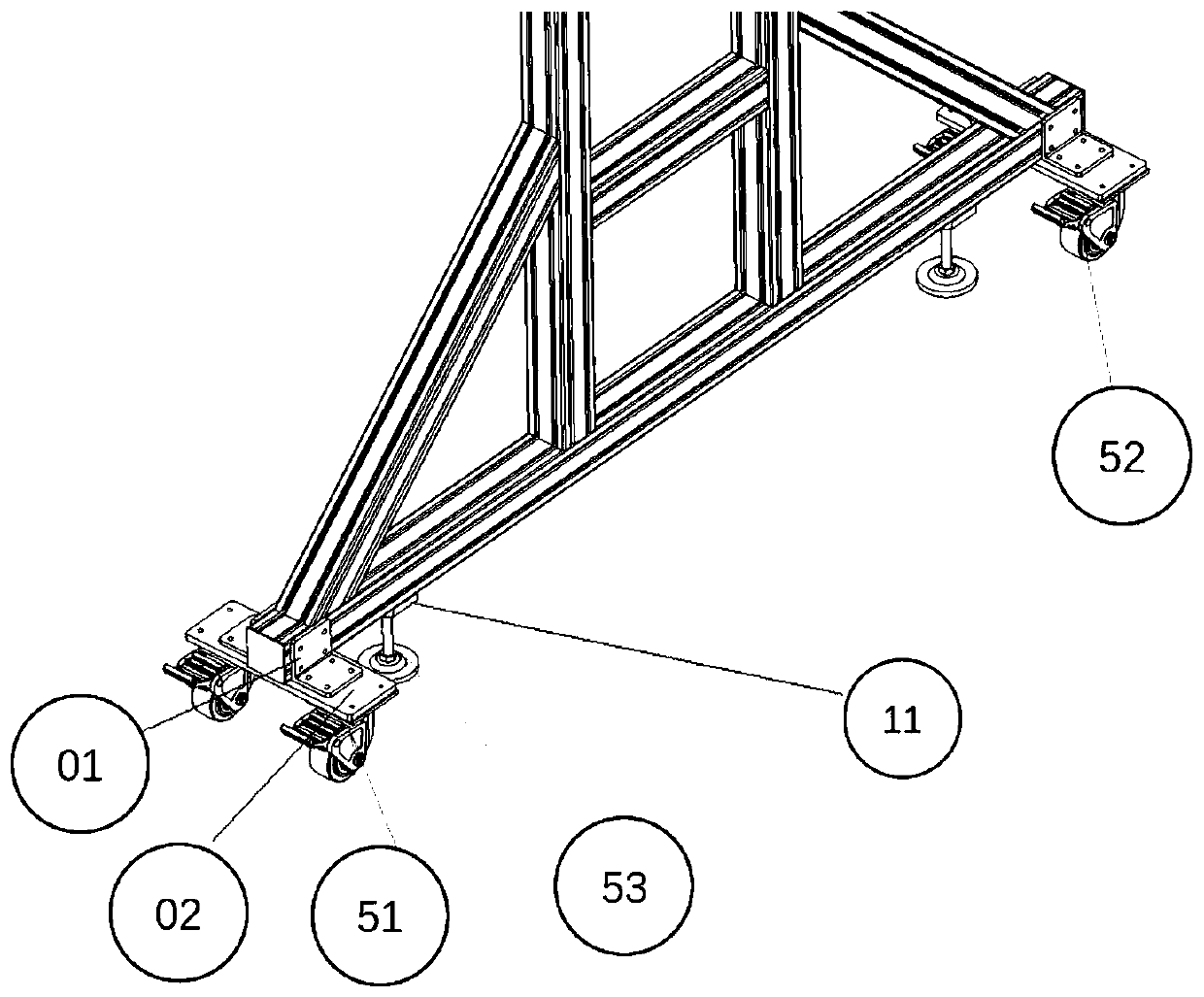

[0033] Among them, the П-shaped balance frame is mainly composed of columns and beams assembled by profiles, and is equipped with casters and telescopic support legs; the main frame of the П-shaped balance frame is composed of columns and beams, and its material is aluminum profiles. The appearance and structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com