A composite film suitable for quick gusset bag making

A technology of composite film and edge insertion, applied in the field of composite film, to reduce direct economic loss, protect the contents, and ensure the first pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

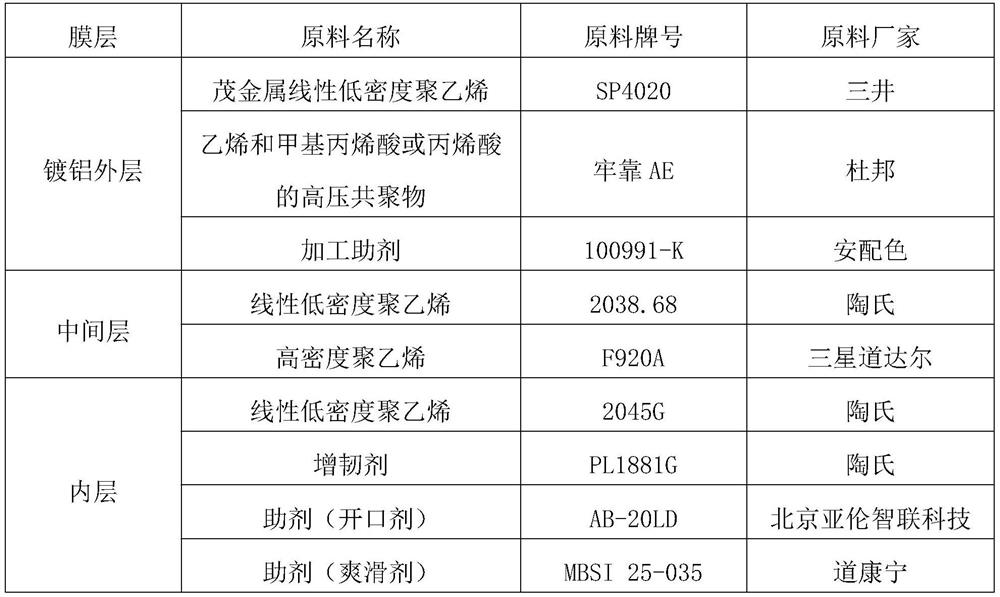

[0021] Raw material sources are shown in table 1 below in the following examples:

[0022] Table 1

[0023]

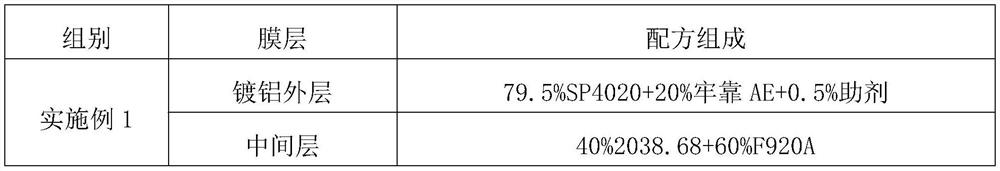

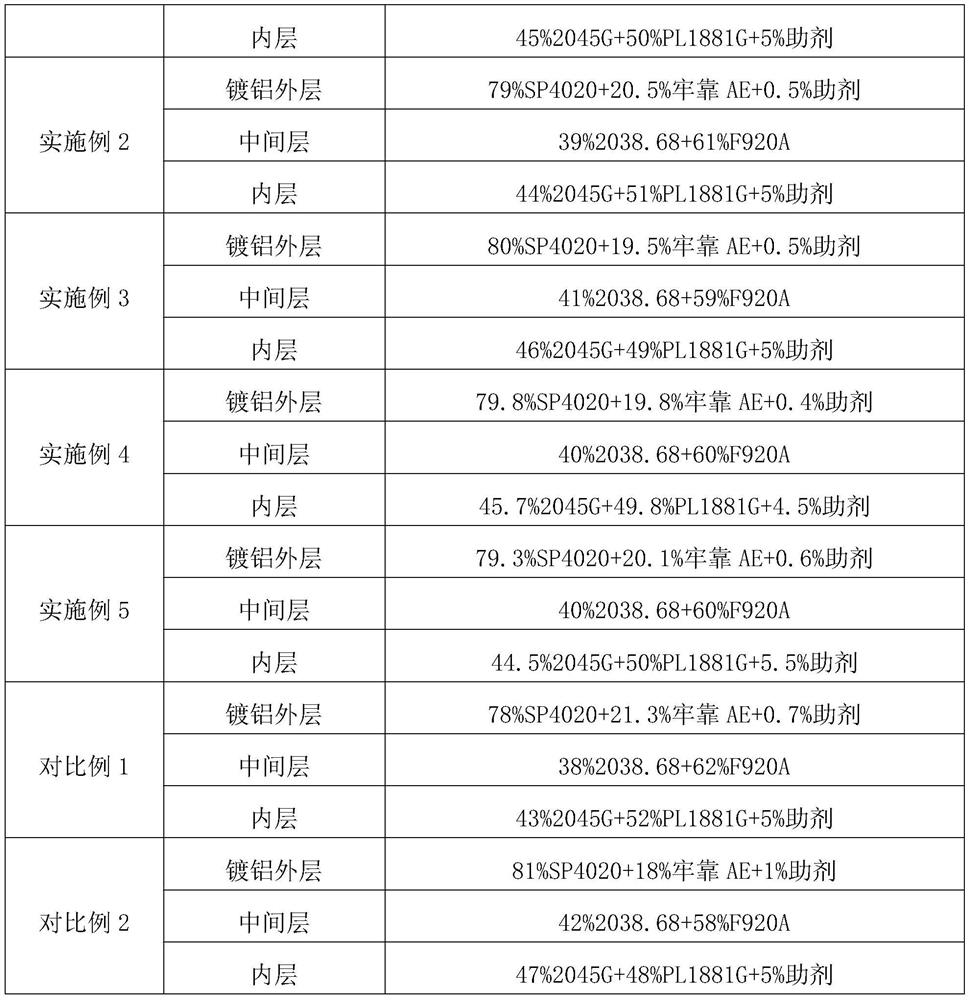

[0024] The formula composition of the aluminized polyethylene film in the composite film in the following examples is as shown in table 2 below:

[0025] Table 2

[0026]

[0027]

[0028] Composite film of the present invention is prepared according to above formula, and concrete preparation method is as follows:

[0029] Step 1, preparation of aluminized polyethylene film

[0030] Preparation of polyethylene film: Add the raw materials in the aluminum-coated outer layer, middle layer and inner layer into the barrel of a co-extrusion blown film machine for melting and co-extrusion, and then undergo film blowing cooling, plywood foaming, corona, trimming, The polyethylene film is obtained by winding treatment; the melting temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com