Preparation method for perfluoroisobutyronitrile

A technology of heptafluoroisobutyronitrile and heptafluoroisobutyramide is applied in the field of preparation of heptafluoroisobutyronitrile, can solve the problems of high cost, difficult to store in the system, low yield and the like, and achieves mild reaction conditions and no three wastes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The embodiment of the present application provides the first preparation method of heptafluoroisobutyronitrile, the specific steps are as follows:

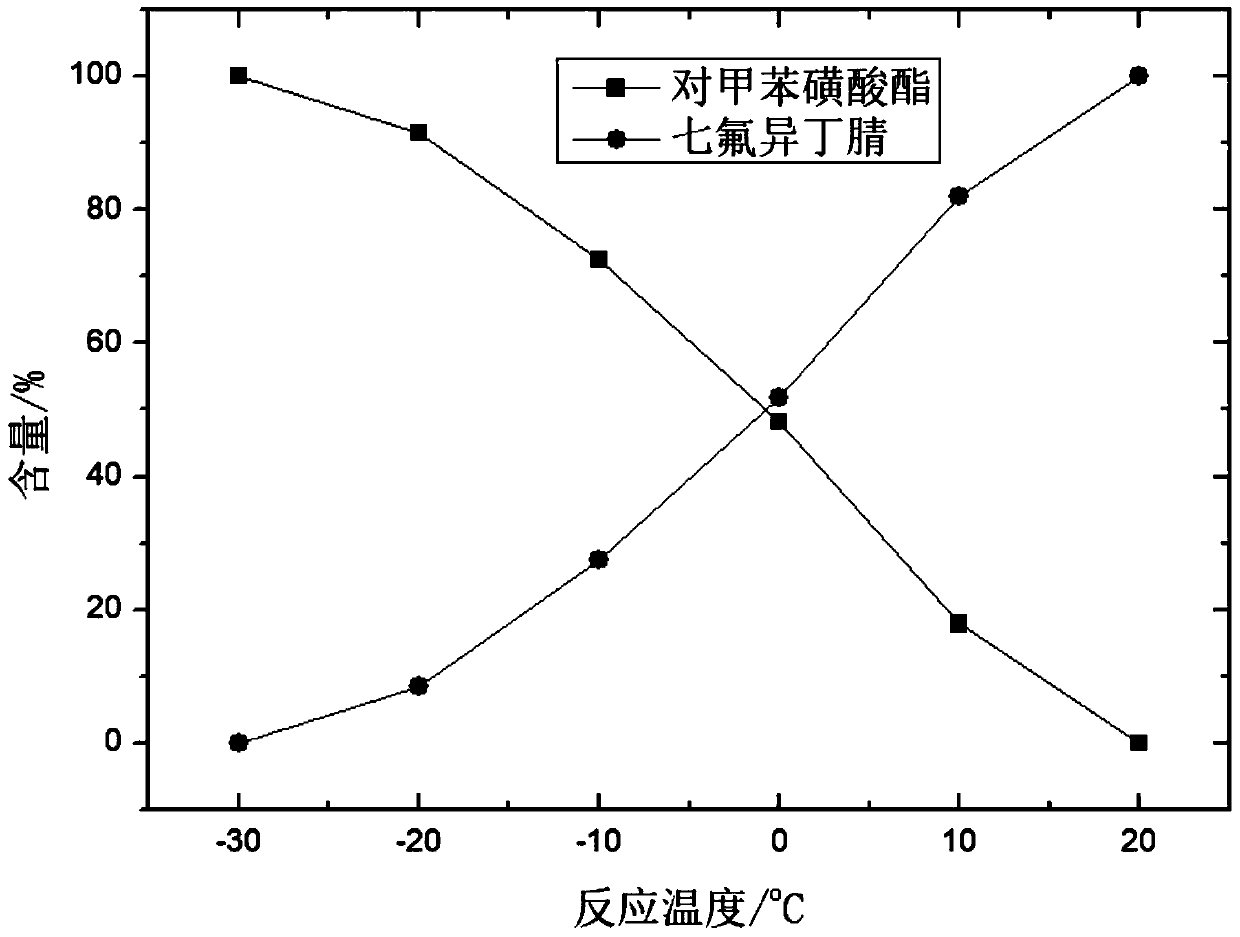

[0038] The autoclave used in the examples of the present application has a volume of 1 L, and the autoclave is equipped with stirring, a thermometer and a heat exchange jacket. Add 0.3 kg of methyl tert-butyl ether, 0.21 kg of p-toluenesulfonyl chloride, and 0.21 kg of heptafluoroisobutyramide into the autoclave, then cool down the autoclave, and add 0.12 kg of triethylamine. Incubate at -30°C for 1 hour; finally analyze the product of the autoclave, the product contains p-toluenesulfonate and the target product heptafluoroisobutyronitrile, and record the p-toluenesulfonate and target product heptafluoroisobutyronitrile Changes in content (deducting the content of other substances). The result is as figure 1 shown.

Embodiment 2

[0040] The embodiment of the present application provides the second preparation method of heptafluoroisobutyronitrile, the specific steps are as follows:

[0041] The autoclave used in the examples of the present application has a volume of 1 L, and the autoclave is equipped with stirring, a thermometer and a heat exchange jacket. Add 0.3 kg of methyl tert-butyl ether, 0.21 kg of p-toluenesulfonyl chloride, and 0.21 kg of heptafluoroisobutyramide into the autoclave, then cool down the autoclave, and add 0.12 kg of triethylamine. Incubate at -20°C for 1 hour; finally analyze the product of the autoclave, the product contains p-toluenesulfonate and the target product heptafluoroisobutyronitrile, and record the p-toluenesulfonate and target product heptafluoroisobutyronitrile Changes in content (deducting the content of other substances). The result is as figure 1 shown.

Embodiment 3

[0043] The embodiment of the present application provides the third preparation method of heptafluoroisobutyronitrile, the specific steps are as follows:

[0044] The autoclave used in the examples of the present application has a volume of 1 L, and the autoclave is equipped with stirring, a thermometer and a heat exchange jacket. Add 0.3 kg of methyl tert-butyl ether, 0.21 kg of p-toluenesulfonyl chloride, and 0.21 kg of heptafluoroisobutyramide into the autoclave, then cool down the autoclave, and add 0.12 kg of triethylamine. Incubate at -10°C for 1 hour; finally analyze the product of the autoclave, the product contains p-toluenesulfonate and the target product heptafluoroisobutyronitrile, and record the p-toluenesulfonate and target product heptafluoroisobutyronitrile Changes in content (deducting the content of other substances). The result is as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com