A Polarizing Beam Splitter with Large Fabrication Tolerance and High Polarization Extinction Ratio

A technology of polarization beam splitter and polarization extinction ratio, which is applied in the direction of instruments, light guides, optics, etc., can solve the problems of small manufacturing tolerance, hindering the large-scale application of single-chip integrated coherent receivers, and increasing the difficulty of manufacturing due to the device structure. To achieve the effect of improving production tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

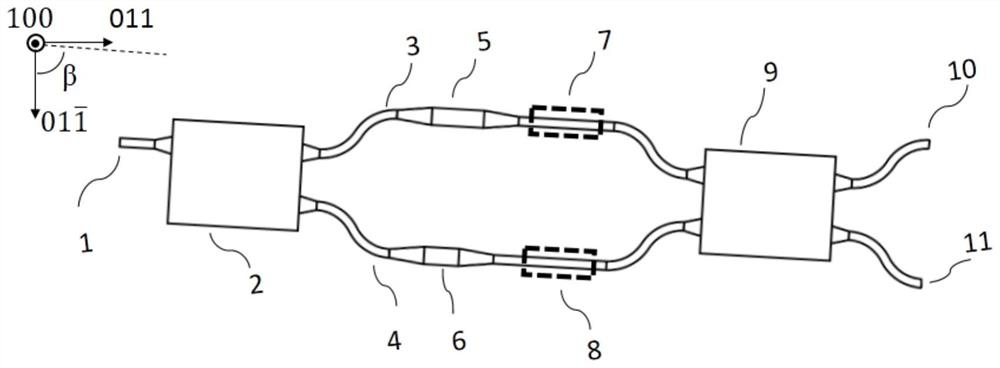

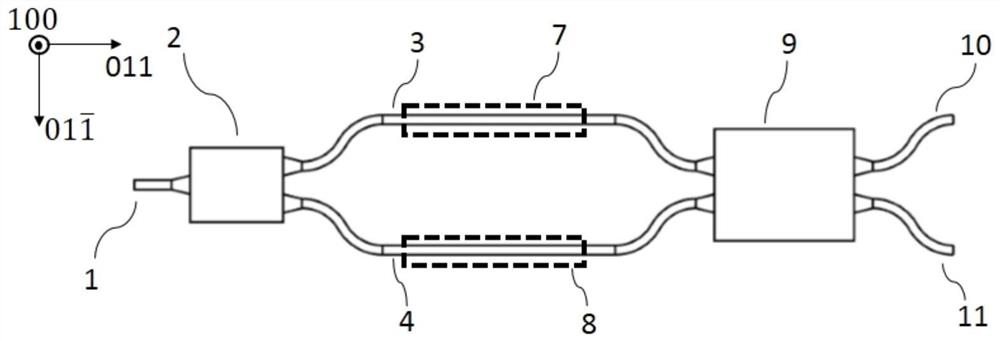

[0042] Example 1 The thickness of the selected waveguide core layer is 0.4 μm, the material is InGaAsP, the width is 2 μm, the waveguide substrate and cover layer are InP, the length of the phase shift waveguide is 2.5mm, and the incident wavelength is 1550nm. The waveguide is oriented with the crystal's The angle β of the direction is 90°, and the width of the waveguide in the birefringent region is consistent with that of the straight waveguide, such as figure 2 shown.

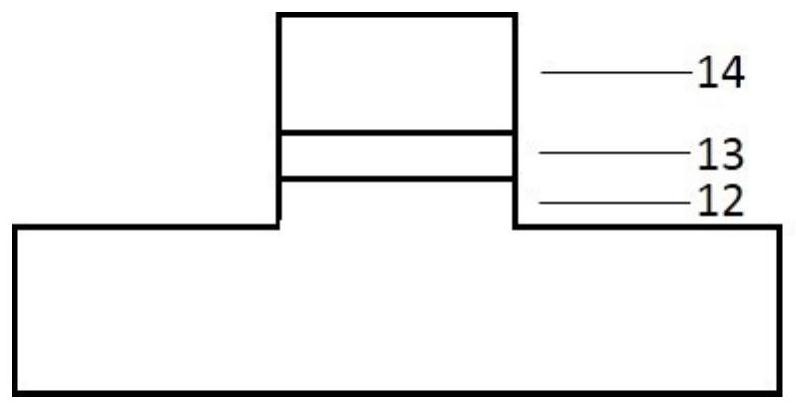

[0043] The waveguide adopts the structure of P-I-N type. image 3 It is a cross-sectional view of the P-I-N waveguide structure, from bottom to top there are N-type doped waveguide substrate 12, undoped waveguide core layer 13 and P-type doped waveguide cover layer 14.

[0044] First, we specifically analyze the first-order electro-optic effect, the second-order electro-optic effect, the carrier dispersion effect and the energy band filling effect.

[0045] The first-order electro-optic effect means tha...

example 2

[0075] In Example 2, the thickness of the waveguide core layer selected is 0.4 μm, the material is InGaAsP, and the width is 2 μm. The waveguide substrate and cover layer are InP. There is a 1.5um thick InGaAs spacer layer at 2 μm below the waveguide core layer. The length of the phase shift waveguide is 2.5mm, the incident wavelength is 1550nm, the upper arm waveguide covers the thermal electrode 15 and the lower arm waveguide electrode 16 . The waveguide is oriented with the crystal's The angle β of the direction is 90°, such as Figure 9 shown.

[0076] The waveguide adopts the structure of P-I-N type. Figure 10 It is a cross-sectional view of the P-I-N waveguide structure. From bottom to top, there are N-type doped waveguide substrate 17, N-type doped spacer layer 18, undoped waveguide core layer 19 and P-type doped waveguide cover layer. 20.

[0077] The heating of the thermal electrode 15 of the upper arm waveguide can change the effective refractive index of the T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com