A magnetorheological elastomer capable of precisely controlling the axial distribution of magnetic particles and its preparation method

A magnetorheological elastomer and magnetic particle technology, which is applied in the direction of magnetic objects, magnetic liquids, and magnetic materials, can solve problems such as difficulties in preparation methods, achieve reasonable formula design, precise control of distribution and content, and improve magnetorheological properties. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

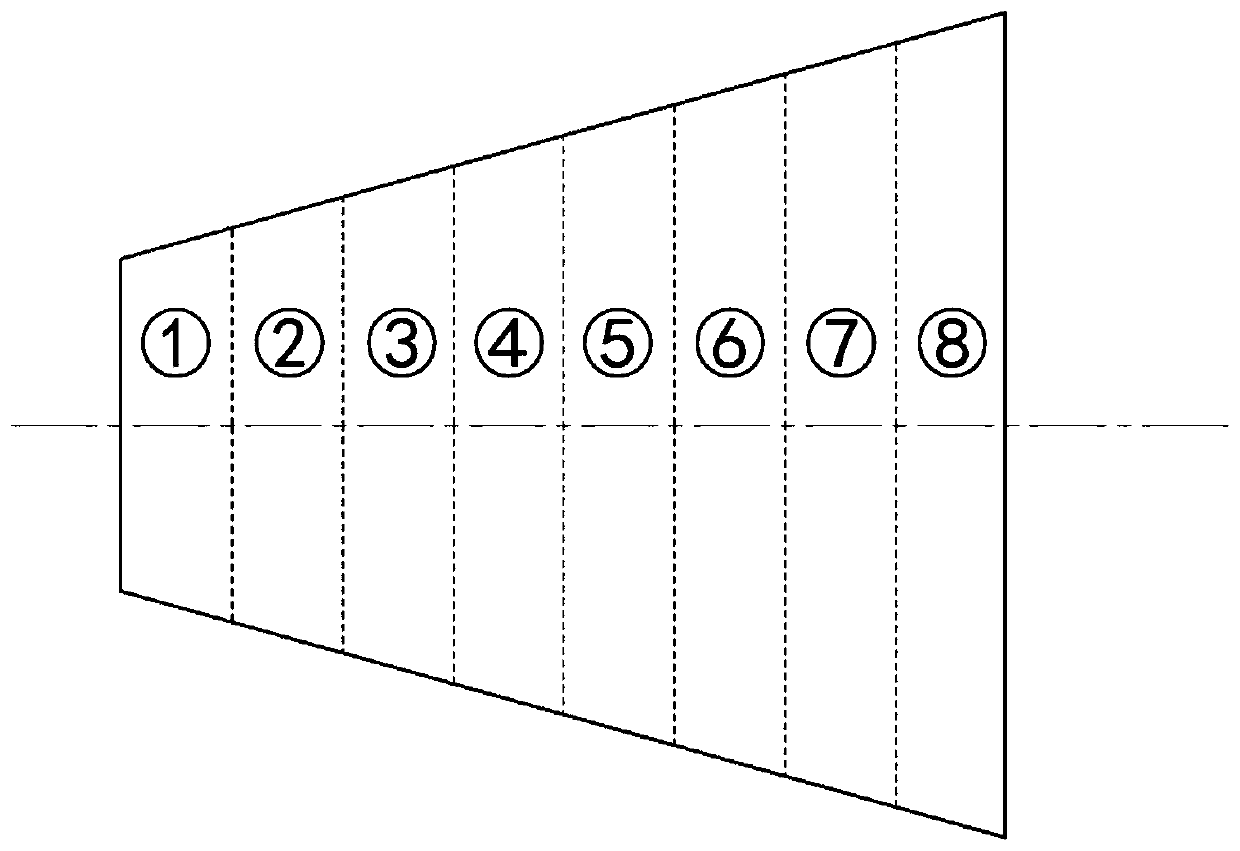

[0020] Prepared by the method of the present invention such as figure 1 The frusto-conical magnetorheological elastomer shown. According to the three-dimensional shape of the circular frustum to be formed, the magnetorheological elastomer to be prepared is divided into 8 equal parts along the axial direction of the vertical bottom surface of the circular frustum (i.e. ①~⑧ in the figure), and the content of magnetic particles added to each part is respectively 10%, 20%, 30%, 40%, 50%, 60%, 70% and 80%, the corresponding rubber matrix content is 80%, 70%, 60%, 50%, 40%, 30%, 20% and 10%, the additive content is 10%; according to the above ratio, the raw materials are weighed, the weighed natural rubber latex solution and the additive are mixed evenly and the obtained mixture is preheated in an oven for 3 to 5 minutes; Add the weighed carbonyl iron powder into the mixture and stir and mix with a high-speed mixer for 10-15 minutes, so that the carbonyl iron powder is evenly distr...

Embodiment 2

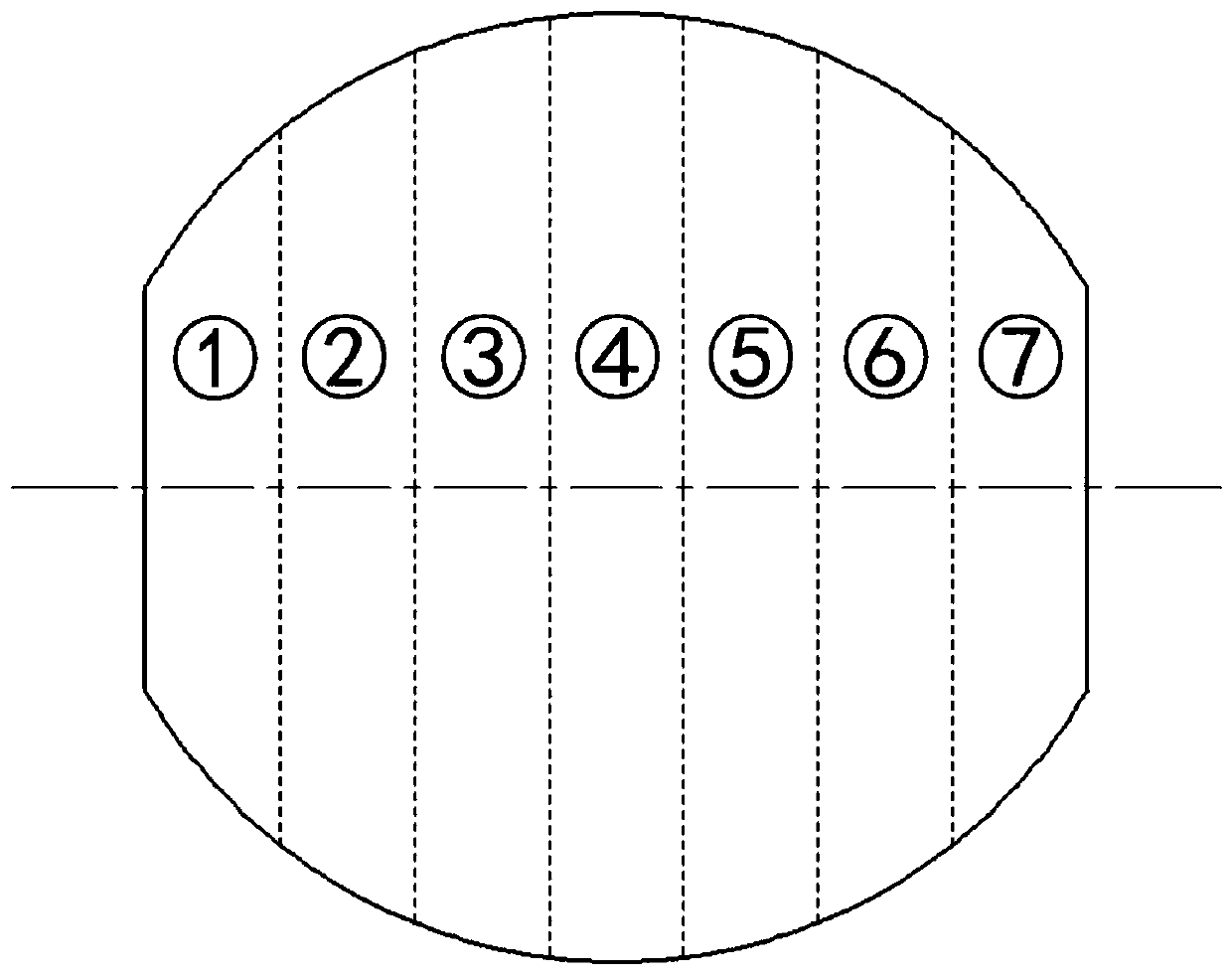

[0022] Prepared by the inventive method such as figure 2 The cylindrical magnetorheological elastomer shown. According to the shape of the drum-shaped member to be formed, the magnetorheological elastomer to be prepared is divided into 7 equal parts in the axial direction (i.e. ①~⑦ in the figure), and the content of magnetic particles added to each part is 20%, 40%, 60%, 80%, 60%, 40% and 20%, the content of the corresponding rubber matrix is 70%, 50%, 30%, 10%, 30%, 50% and 70%, the additive content is 10%; weigh the raw materials according to the above ratio, mix the weighed natural rubber latex solution and additives evenly, and place the resulting mixture in an oven to preheat for 3 to 5 minutes; add the weighed carbonyl iron powder into the mixture and use Stir and mix with a high-speed mixer for 10 to 15 minutes, so that the carbonyl iron powder is evenly distributed in the natural rubber latex solution; use a vacuum pump to vacuumize the mixture of natural rubber la...

Embodiment 3

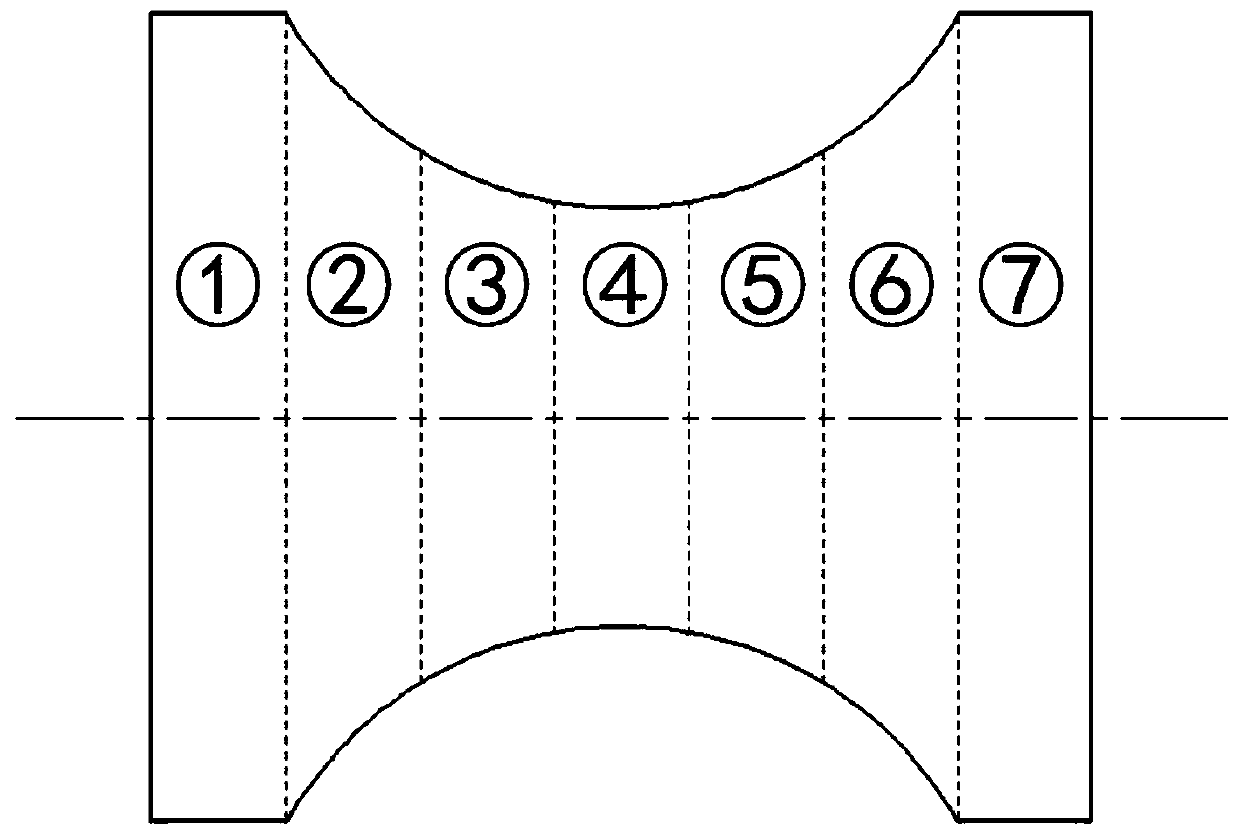

[0024] Prepared by the inventive method such as image 3 The cylindrical magnetorheological elastomer shown. According to the shape of the cylindrical member to be formed, the magnetorheological elastomer to be prepared is divided into 7 equal parts in the length direction (i.e. ①~⑦ in the figure), and the content of magnetic particles added to each part is 80%, 60% %, 40%, 20%, 40%, 60% and 80%, the content of the corresponding rubber matrix is 10%, 30%, 50%, 70%, 50%, 30% and 10%, and the additive content is 10% %; weigh the raw materials according to the above ratio, mix the weighed natural rubber latex solution and additives evenly and place the resulting mixture in an oven to preheat for 3 to 5 minutes; add the weighed carbonyl iron powder into the mixture and use a high-speed Stir and mix with the mixer for 10-15 minutes, so that the carbonyl iron powder is evenly distributed in the natural rubber latex solution; use a vacuum pump to vacuumize the mixture of the natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com