A preparation method of magnetorheological elastomer with controlled radial distribution of magnetic particles

A magnetorheological elastomer and magnetorheological elasticity technology, applied in the field of magnetorheological materials, can solve the problems of increasing the difficulty of manufacturing magnetic field generating devices, limiting the application of magnetorheological elastomers, prolonging the production cycle, etc., and achieving a long production cycle , Improving the magnetorheological effect and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

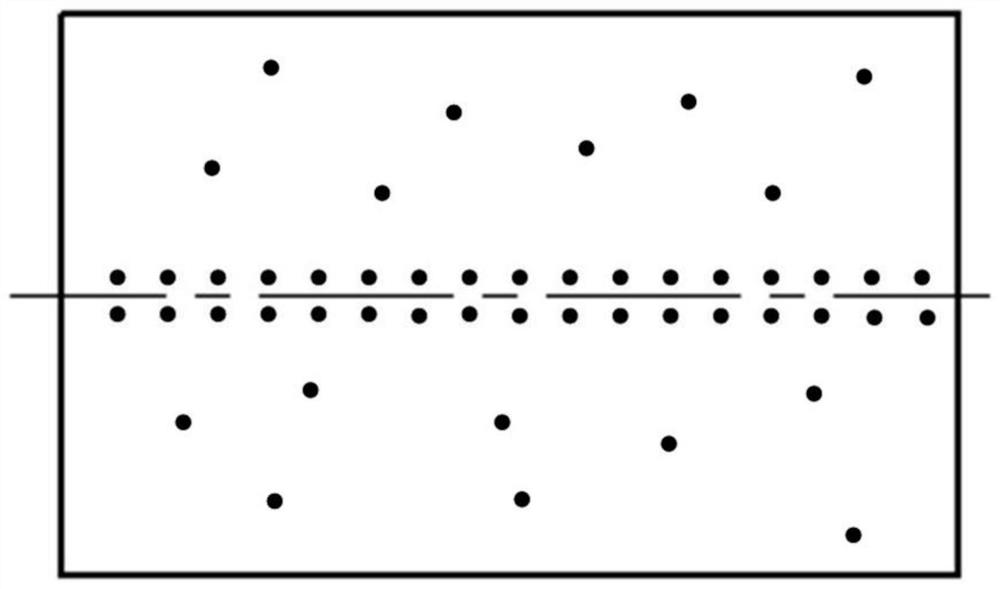

[0033] Prepared by the method of the present invention such as figure 1 Shown is a magnetorheological elastomer in which most of the magnetic particles are distributed along the central axis of the silicone rubber matrix. Prepare raw materials according to the ratio of 20% silicone rubber, 60% carbonyl iron powder, and 20% plasticizer, and place the prepared silicone rubber and carbonyl iron powder in a vacuum drying oven for 2 hours at 80°C; Add the uniform mixture of the two to the fluid silicone rubber raw material and stir it with a high-speed mixer for 10-15 minutes to make the magnetic particles evenly distributed in the rubber matrix; after stirring evenly, put the mixture into a vacuum container and evacuate it for 30- Remove the air bubbles inside the mixture for 35 minutes; pour the air-removed mixture into a mold and place it horizontally, seal it, and solidify it while rotating around the horizontal axis. When the rotation speed of the mold around the axis is less...

specific Embodiment approach 2

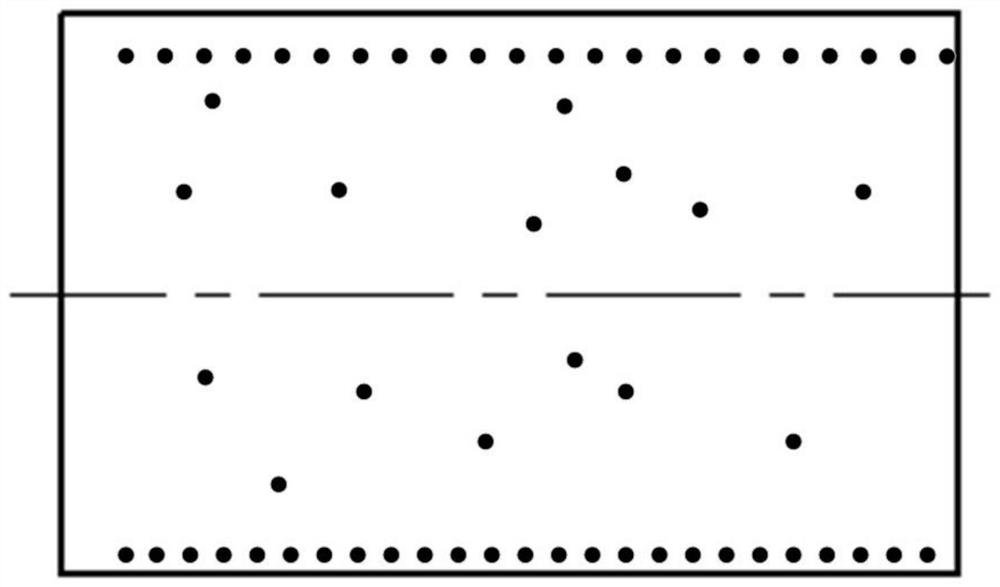

[0035] The method of the present invention prepares as figure 2 Shown is a magnetorheological elastomer with mostly magnetic particles distributed around the circumference of a silicone rubber matrix. Prepare raw materials according to the ratio of 20% silicone rubber, 60% carbonyl iron powder, and 20% plasticizer, and place the prepared silicone rubber and carbonyl iron powder in a vacuum drying oven for 2 hours at 80°C; Add the uniform mixture of the two to the fluid silicone rubber raw material and stir it with a high-speed mixer for 10-15 minutes to make the magnetic particles evenly distributed in the rubber matrix; after stirring evenly, put the mixture into a vacuum container and evacuate it for 30- Remove the air bubbles inside the mixture for 35 minutes; pour the air-removed mixture into a mold and place it horizontally, and solidify while rotating. When the rotation speed of the mold around the axis is greater than 200r / min, the centrifugal force on the magnetic pa...

specific Embodiment approach 3

[0037] The method of the invention is used to prepare the magnetorheological elastomer in which the magnetic particles are randomly distributed in the radial direction in the silicone rubber matrix. Prepare raw materials according to the ratio of 20% silicone rubber, 60% carbonyl iron powder, and 20% plasticizer, and place the prepared silicone rubber and carbonyl iron powder in a vacuum drying oven for 2 hours at 80°C; Add the uniform mixture of the two to the fluid silicone rubber raw material and stir it with a high-speed mixer for 10-15 minutes to make the magnetic particles evenly distributed in the rubber matrix; after stirring evenly, put the mixture into a vacuum container and evacuate it for 30- Remove the air bubbles inside the mixture for 35 minutes; pour the air-removed mixture into a mold and place it horizontally, and solidify while rotating. Controlling the rotation speed of the mold around the central axis and its variation, that is, the rotation speed-time cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com