Film-soil separating device for farmland residual film recycling

A separation device and residual film recovery technology, which is applied in the field of agricultural machinery, can solve the problems of reduced value of residual film and the lack of impurity and soil removal mechanism of the model, so as to improve the separation rate and efficiency of film and soil, complete the separation of film and soil, The effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

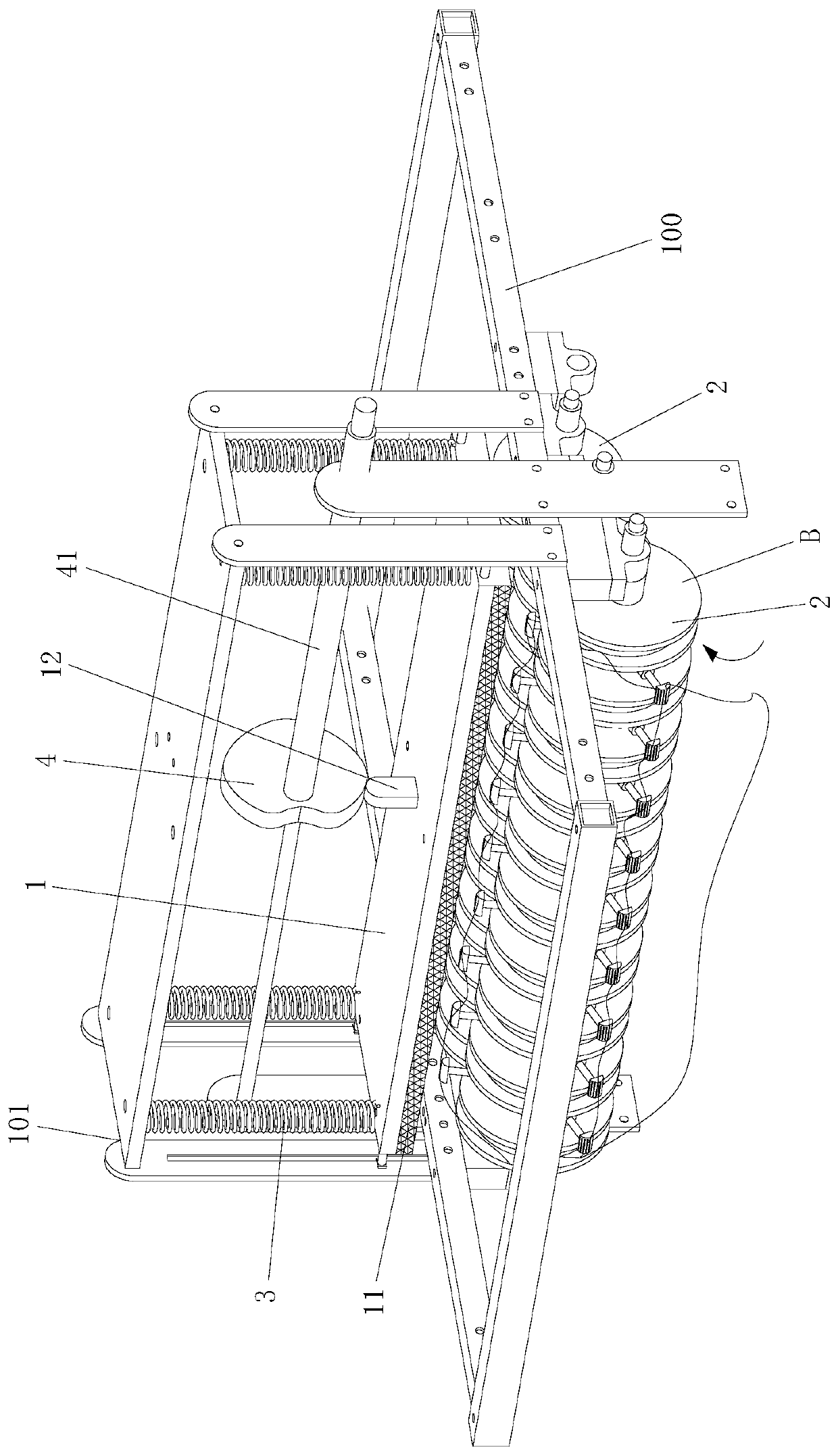

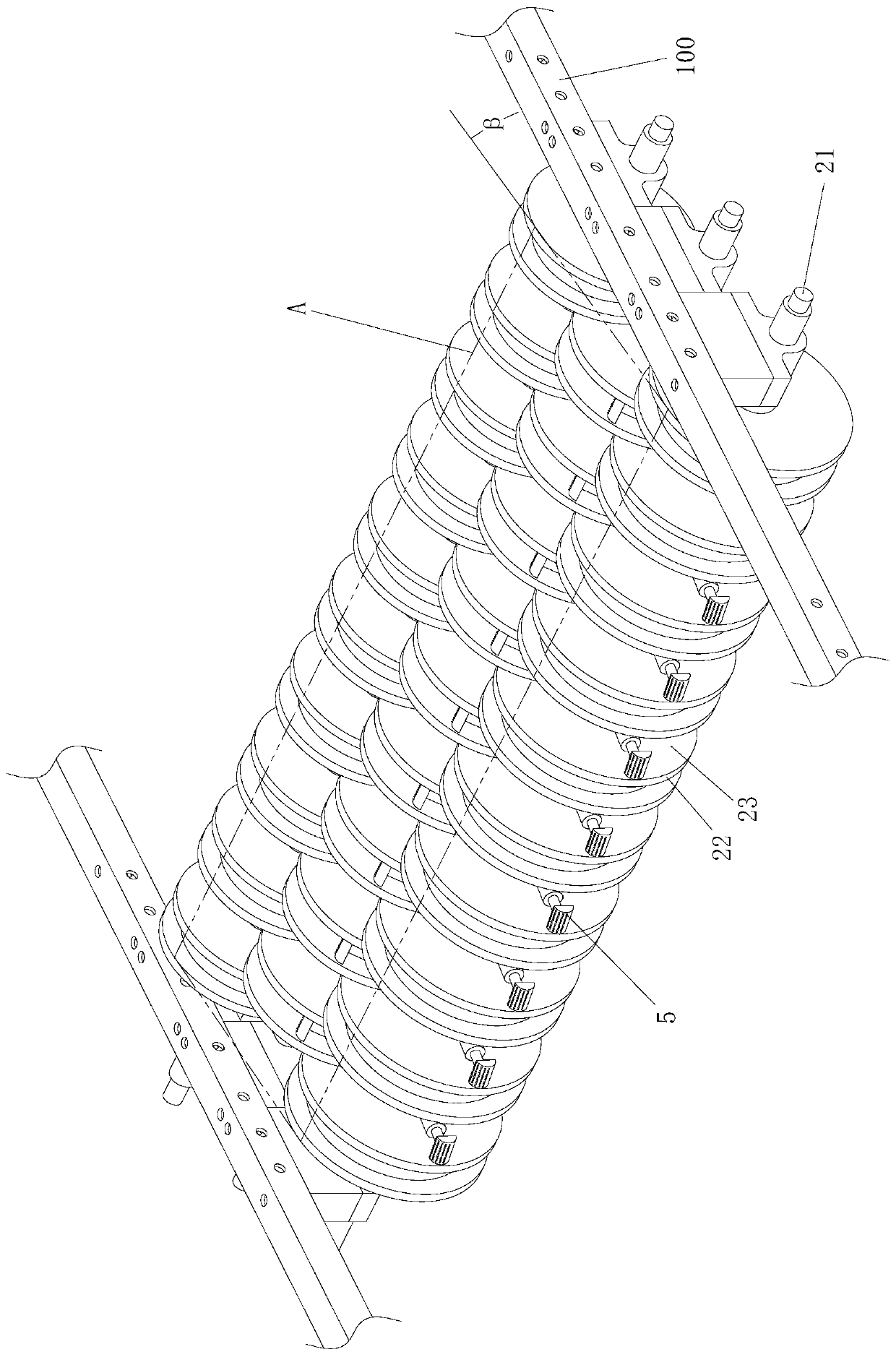

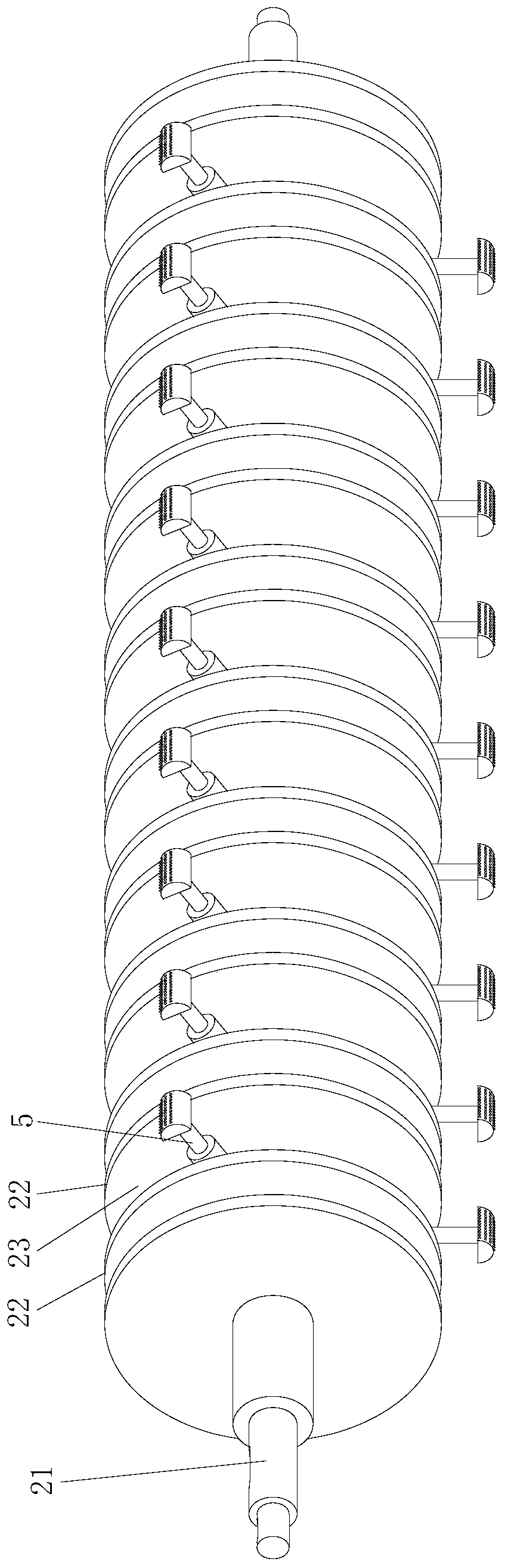

[0028] like figure 1 and figure 2 As shown, the membrane soil separation device for the recovery of farmland residual membranes in this embodiment includes a frame 100, a lamination plate 1 and three separation drums 2 (in other embodiments, there may be two or more than four), The three separation rollers 2 are installed on the frame 100 at intervals and arranged side by side. The lamination plate 1 is connected to a lift drive assembly and is driven by the lift drive assembly to reciprocate up and down to press down the three separation rollers 2 intermittently. The separation device also includes a rotary drive assembly for driving all the separation drums 2 to rotate in the same direction. When the membrane-soil separation device is in operation, all the separation drums 2 are driven by the rotary drive assembly to rotate in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com