Micro-bubble hydrogenation reactor and application thereof

A hydrogenation reactor and hydrogenation reaction technology, applied in chemical instruments and methods, hydrocarbon oil cracking, petroleum industry, etc., can solve the problem of blockage of microporous metal-containing precipitates on the tube, insufficient gas-liquid reaction space, and gas-liquid mixing Small chamber volume and other issues, to avoid local overheating and deactivation, high industrial application value, and promote the effect of gas-liquid mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

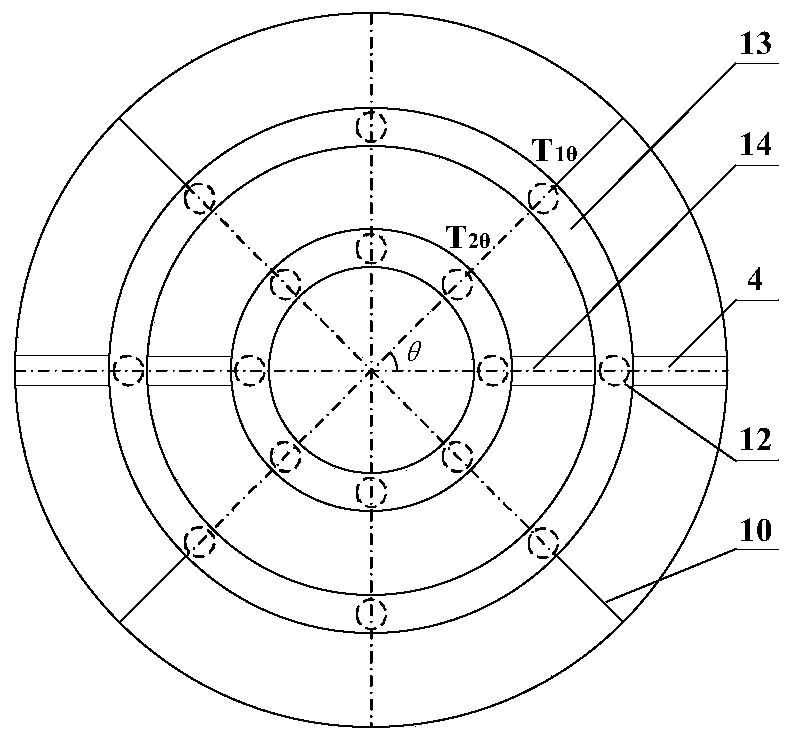

[0120] This embodiment provides a kind of upflow type micro-bubble hydrogenation reactor, such as Figure 4 As shown, the reactor includes a reactor main body and a membrane tube microbubble generating device 5;

[0121] The reactor body includes a cylindrical reactor shell 2 with an inner diameter of 280mm arranged on the outermost side of the reactor. The inside of the reactor shell 2 is sequentially provided with a gas-liquid distributor 3, a gas injection pipe 4, Catalyst bed 6 and metal screen 7, the gas injection pipe 4 is located on both sides of the lower part of the catalyst bed 6, a feed inlet 1 is provided directly below the reactor shell 2, and a feed port 1 is provided directly above the reactor shell 2 There is an exhaust port 8, and a discharge port 9 is provided on the upper side; the reactor shell 2 is made of plexiglass, and the catalyst bed 6 includes catalyst particles required for hydrogenation reaction, and the gas-liquid distribution The device 3 is a s...

Embodiment 2

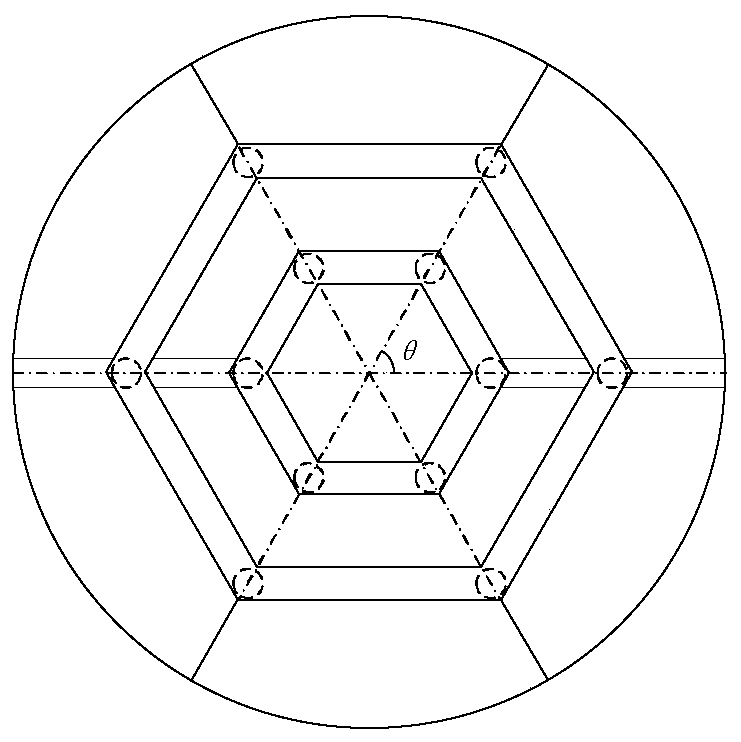

[0129] This embodiment provides an upflow micro-bubble hydrogenation reactor, which includes a reactor body and a membrane tube micro-bubble generating device 5;

[0130] The reactor body includes a cylindrical reactor shell 2 with an inner diameter of 280mm arranged on the outermost side of the reactor. The inside of the reactor shell 2 is sequentially provided with a gas-liquid distributor 3, a gas injection pipe 4, Catalyst bed 6 and metal screen 7, the gas injection pipe 4 is located on both sides of the lower part of the catalyst bed 6, a feed inlet 1 is provided directly below the reactor shell 2, and a feed port 1 is provided directly above the reactor shell 2 There is an exhaust port 8, and a discharge port 9 is provided on the upper side; the reactor shell 2 is made of plexiglass, and the catalyst bed 6 includes catalyst particles required for hydrogenation reaction, and the gas-liquid distribution The device 3 is a sieve plate distributor, the aperture of the sieve h...

Embodiment 3

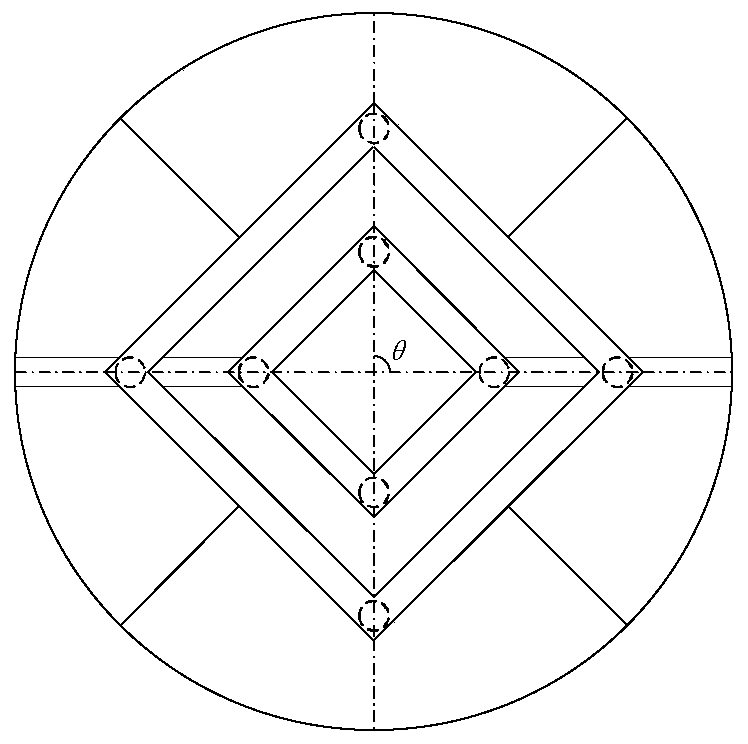

[0135] This embodiment provides an upflow micro-bubble hydrogenation reactor, which includes a reactor body and a membrane tube micro-bubble generating device 5;

[0136] The reactor body includes a cylindrical reactor shell 2 with an inner diameter of 400 mm arranged on the outermost side of the reactor. The inside of the reactor shell 2 is sequentially provided with a gas-liquid distributor 3, a gas injection pipe 4, Catalyst bed 6 and metal screen 7, the gas injection pipe 4 is located on both sides of the lower part of the catalyst bed 6, a feed inlet 1 is provided directly below the reactor shell 2, and a feed port 1 is provided directly above the reactor shell 2 There is an exhaust port 8, and a discharge port 9 is provided on the upper side; the reactor shell 2 is made of plexiglass, and the catalyst bed 6 includes catalyst particles required for hydrogenation reaction, and the gas-liquid distribution The device 3 is a sieve plate distributor, the aperture of the sieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fill height | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com