Multi-station workbench

A workbench, multi-station technology, applied in workbenches, manufacturing tools, multi-purpose machinery, etc., can solve problems such as only one placement method of materials, unreasonable workbench design, and incompatibility with the development direction, saving materials. , Conducive to processing, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

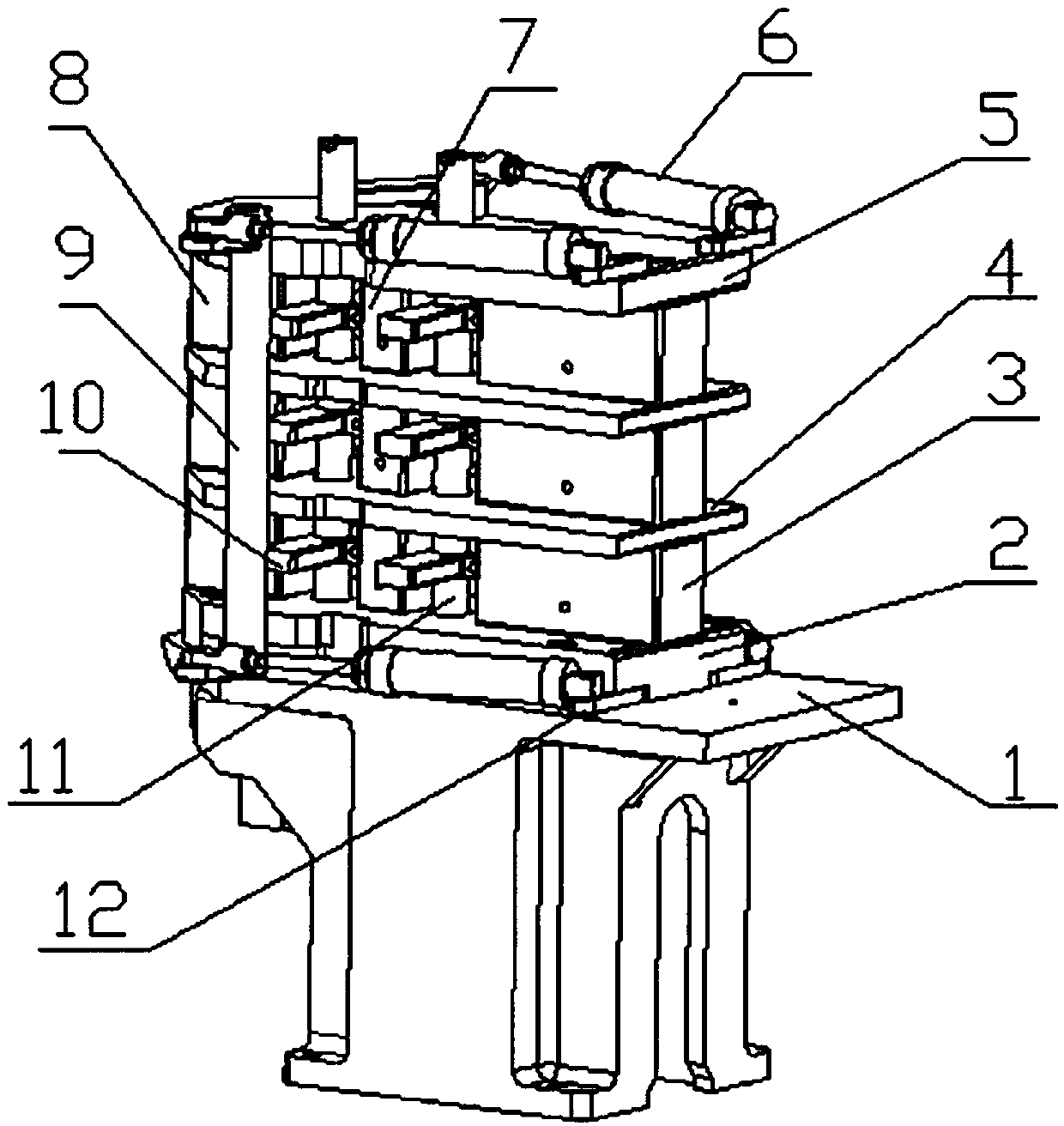

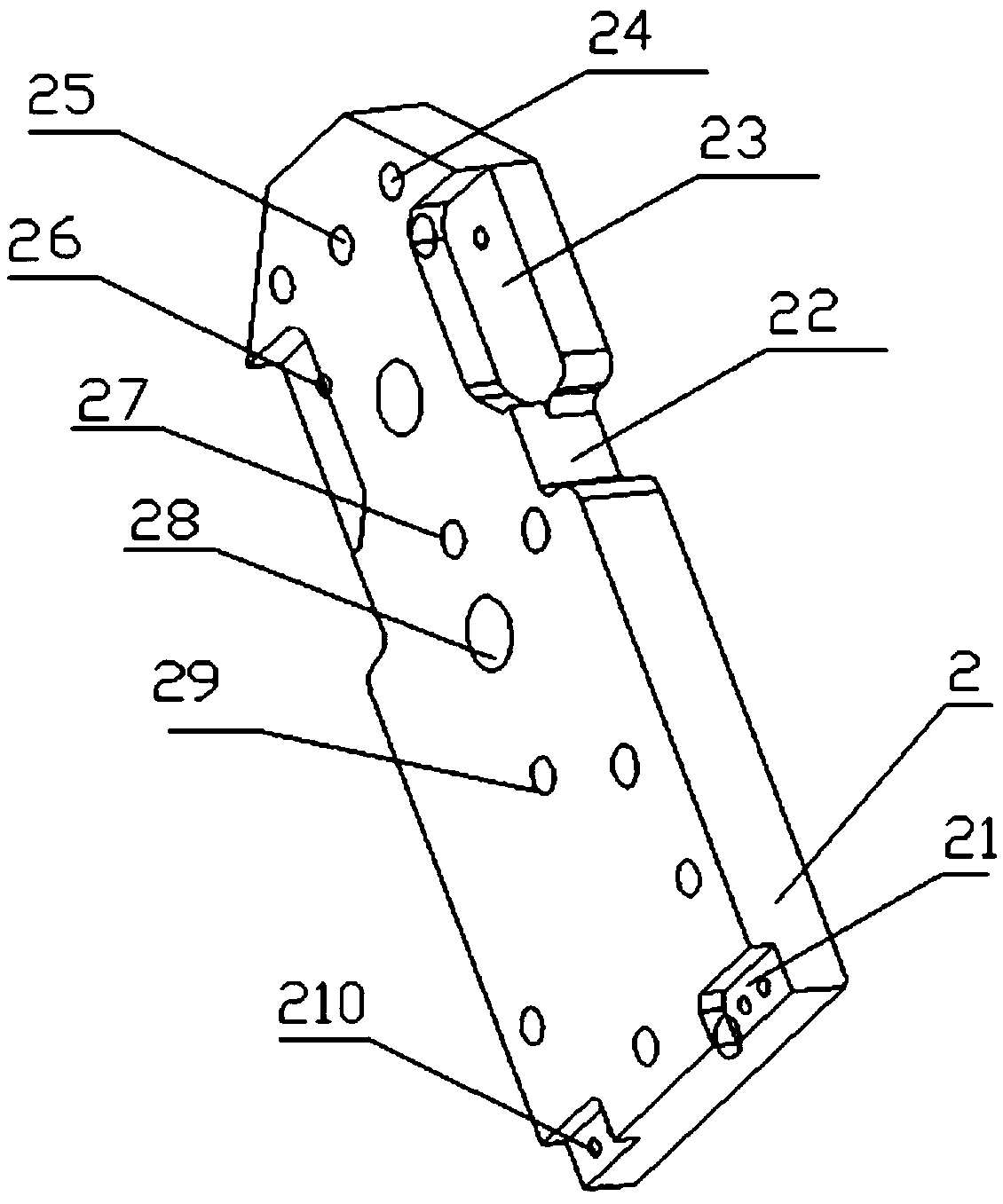

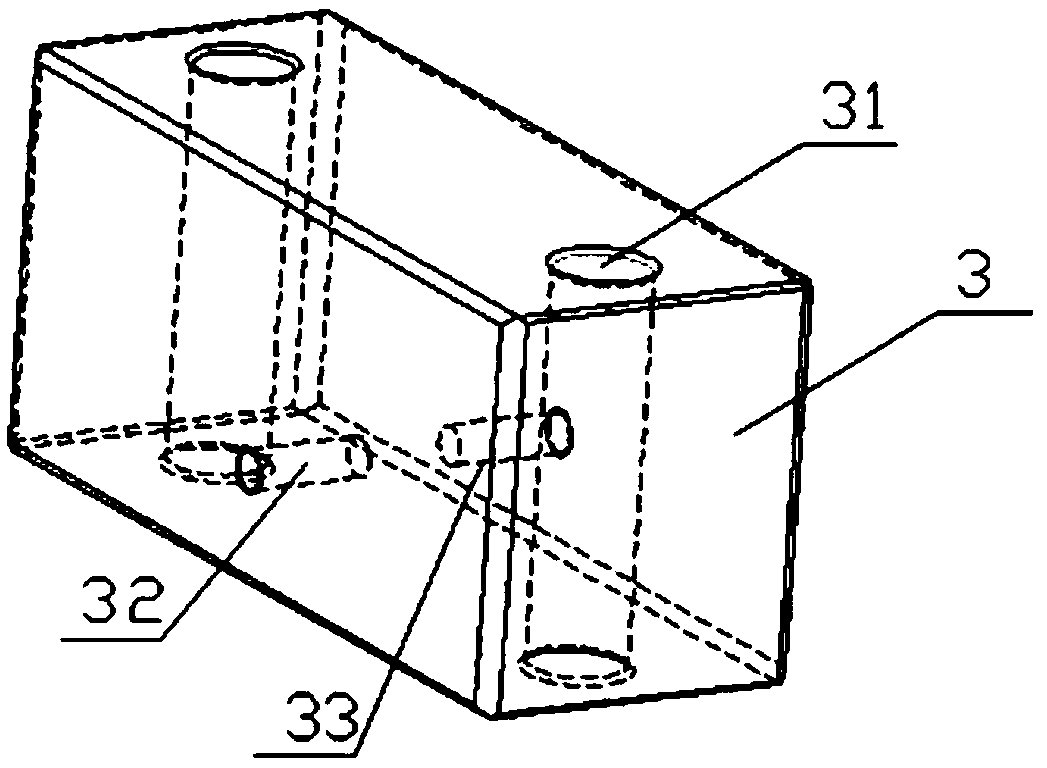

[0039] The invention discloses a multi-station workbench. The multi-station workbench includes a work base 1, a bottom plate 2, a middle plate 4, an upper plate 5, a cylinder 6, a middle backer, a two-way pressure plate 10, a cylinder 6 and a guide rod 11, The rear connection plate 12 of the cylinder, the bottom plate 2 are installed on the working base 1, several middle plates 4 are arranged at intervals above the bottom plate 2, and the upper plate 5 is on the uppermost middle plate 4 and there is a space between the middle plate 4 Between the upper plate 5 and the uppermost middle plate 4, between several middle plates 4, between the lowermost middle plate 4 and the bottom plate 2, a middle backer and a two-way pressure plate 10 are arranged respectively, and the middle backer is located in the middle position in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com