Transportation and guiding equipment for glass laser cutting

A technology of glass laser and equipment, which is applied in the field of transportation and conduction equipment for glass laser cutting. It can solve the problems of glass affecting economic benefits, easy to bump in handling, and no glass panel, so as to prevent offset and position deviation, and avoid inadvertent drop. , the effect of eliminating health and environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

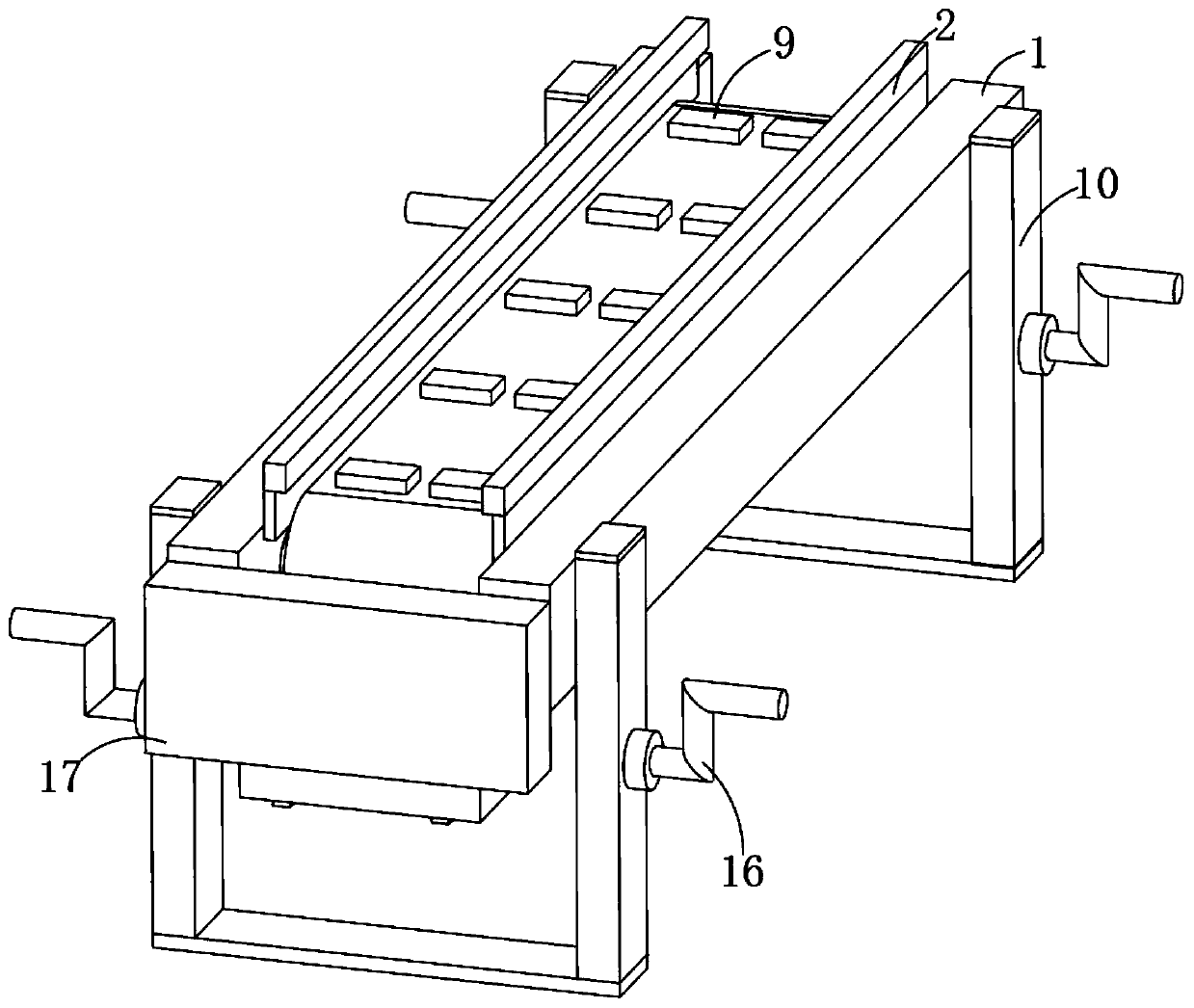

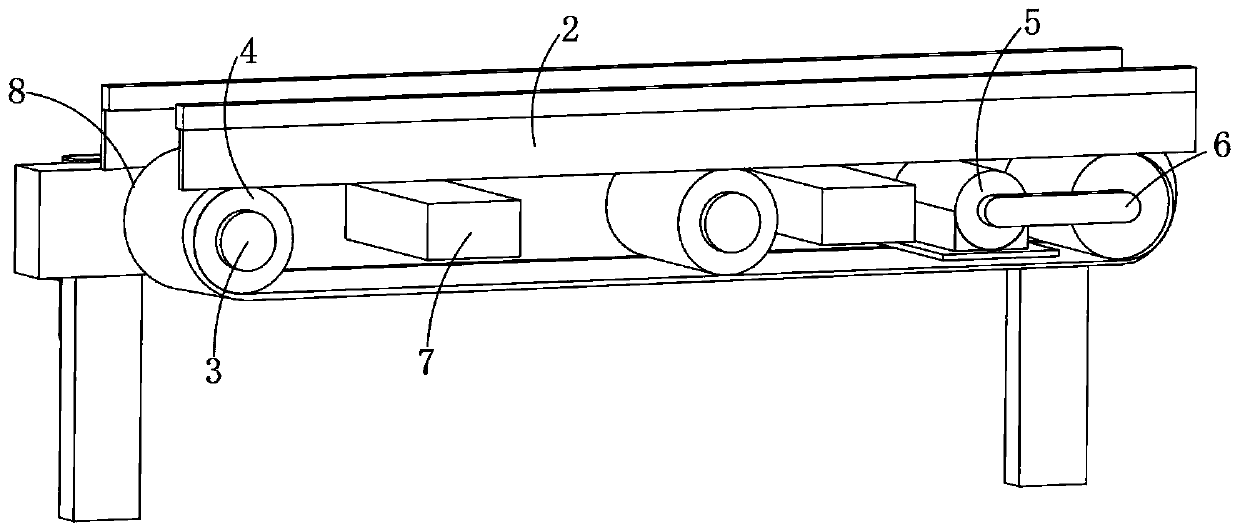

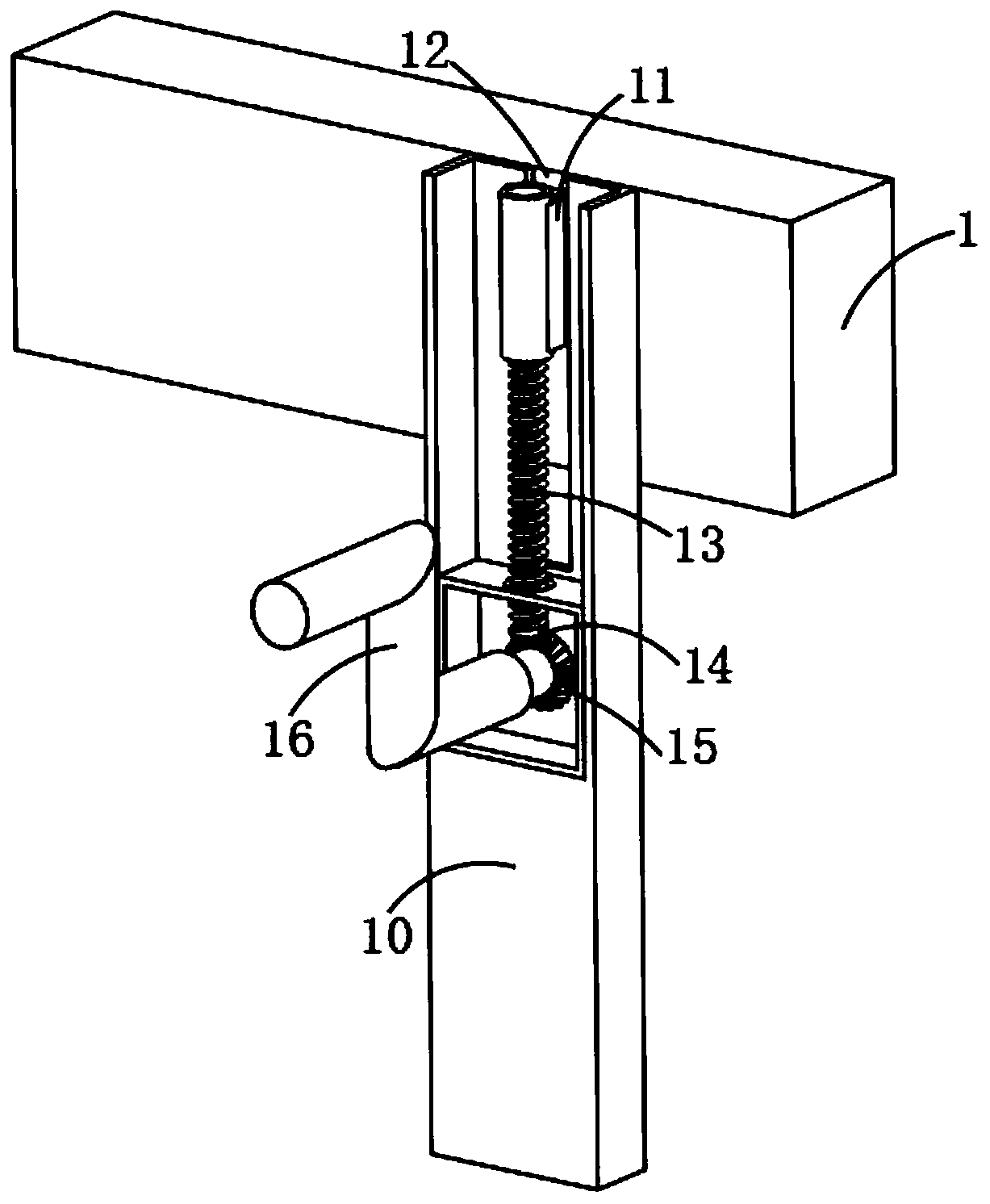

[0025] Example: such as Figure 1-4 As shown, the present invention provides a technical solution for transportation and conduction equipment for glass laser cutting, which includes a bracket 1, a partition plate 2 is welded on the top of one side of the bracket 1, and connecting rods 3 are equidistantly arranged in the middle of the inner side of the bracket 1, and the outer surface of the connecting rod 3 A drum 4 is sleeved, one end of the drum 4 is connected to a transmission shaft 6, and one end of the transmission shaft 6 is connected to a motor 5, the outer surface of the drum 4 is sleeved with a conveyor belt 8, and the outer surface of the conveyor belt 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com