A Multifunctional Clamping Device for Calibration of Thin Film Thermocouple Sensors

A technology of thermocouple sensor and clamping device, which is applied to measuring devices, instruments, measuring heat, etc., to achieve the effects of improving reliability, reducing thermoelectric potential loss, and accurate and reliable calibration results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Clamping and positioning of sheet thin film thermocouple sensor:

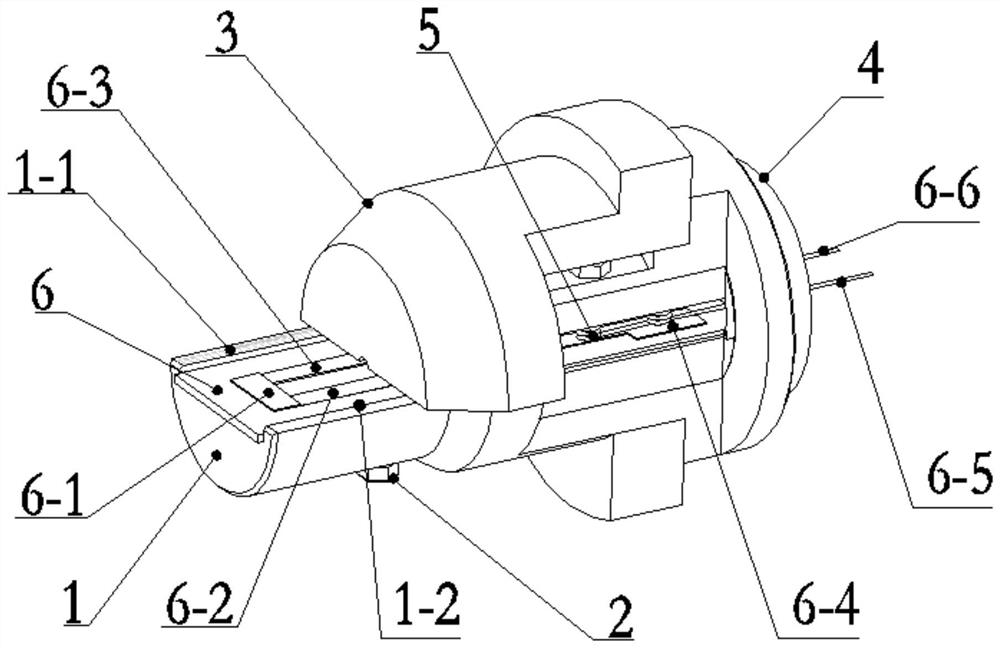

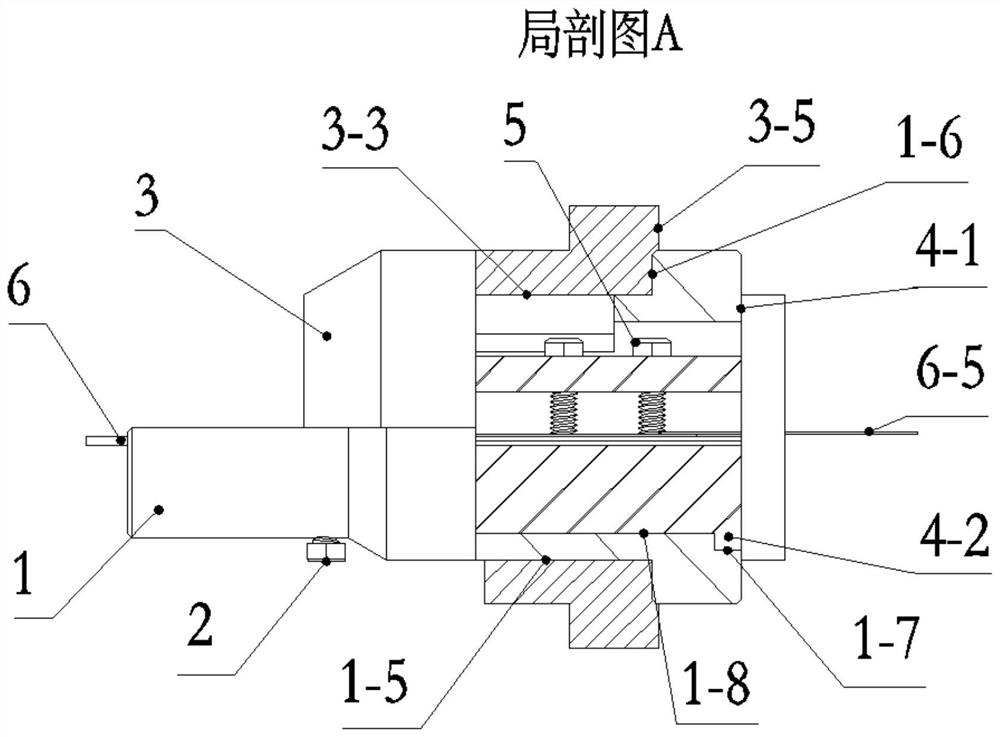

[0046] Such as Figure 8 As shown, the sheet-shaped thin-film thermocouple sensor 6 is mainly composed of a hot junction 6-1 (temperature measuring end / hot end), a thin-film thermal electrode 1 6-2, a thin-film thermal electrode 2 6-3, a cold junction (compensation end / cold end ) 6-4, a compensation wire 6-5, a compensation wire 2 6-6 and an insulating base 6-7. When calibrating, put the sheet-shaped thin-film thermocouple sensor 6 into the sensor slot 1-2 at the front end of the inner conical sleeve 1, and use the scale scale 1-1 at the right end of the sensor slot 1-2 for positioning to ensure that the sensor can be used in multiple calibration experiments. The temperature measurement point in the process is the same, or adjust the installation position of the sensor according to the need, so that it can be inserted into the designated position of the furnace for temperature measurement. After the po...

Embodiment 2

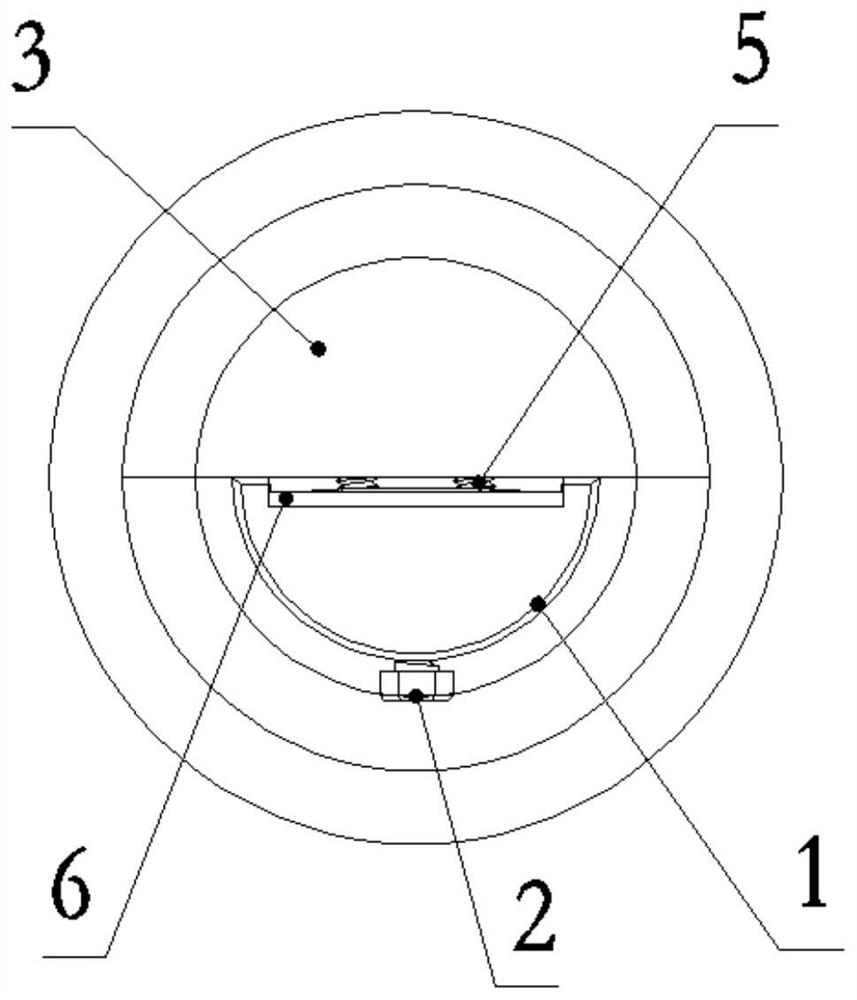

[0048] In order to make the temperature measurement of the thin-film thermocouple sensor more accurate, the temperature of the calibration furnace should be kept constant first. The overall diameter of the device is consistent with the inner diameter of the furnace. When calibrating, it is only necessary to insert the assembled fixture device into the furnace mouth so that the outer conical semicircle The outer surface of the sleeve is close to the furnace wall, and the insertion depth is until the outer conical semicircular sleeve snap ring 3-4 fits the furnace mouth, which realizes the heat preservation of the furnace simply and conveniently, making the ambient temperature of the thermocouple temperature measuring end ideal The required measurement temperature reduces experimental errors due to heat loss. In addition, in order to prevent the cold end (compensation end) 6-4 of the thermocouple sensor from being affected by the heat radiation of the furnace, it is necessary to ...

Embodiment 3

[0051] Sensor compensation wire connection:

[0052] Such as Figure 7 As shown, it is a three-dimensional schematic diagram of the sensor lead fixture tooling. The compensation wire of the sheet-shaped film thermocouple sensor 6 is installed and fixed by mechanical clamping method, and the thermocouples are placed in the thermocouple slots 4-5 of the fixture tooling. The short set screw 5 with the same length and diameter passes through the clamp threaded hole 4-4, so that the compensation wire 1 6-5 and the compensation wire 2 6-6 are respectively pressed on the surface of the pin 6-5 corresponding to the thermal electrode, and the completion The lead wires are connected so that the temperature measurement signal can be stably output to the instrument. Subsequently, the outer surface 4-3 of the fixture is inserted into the sleeve along the inner surface 1-8 of the inner conical sleeve. In order to prevent the relative displacement of the two during the calibration process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com