Method for determining hole closing temperature of diaphragm

A closed-cell temperature and measurement method technology, which is applied in the investigation stage/state change, etc., can solve the problems of high sealing requirements, long measurement time, and leakage of conductive liquid, so as to increase test efficiency, save test time, and avoid The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

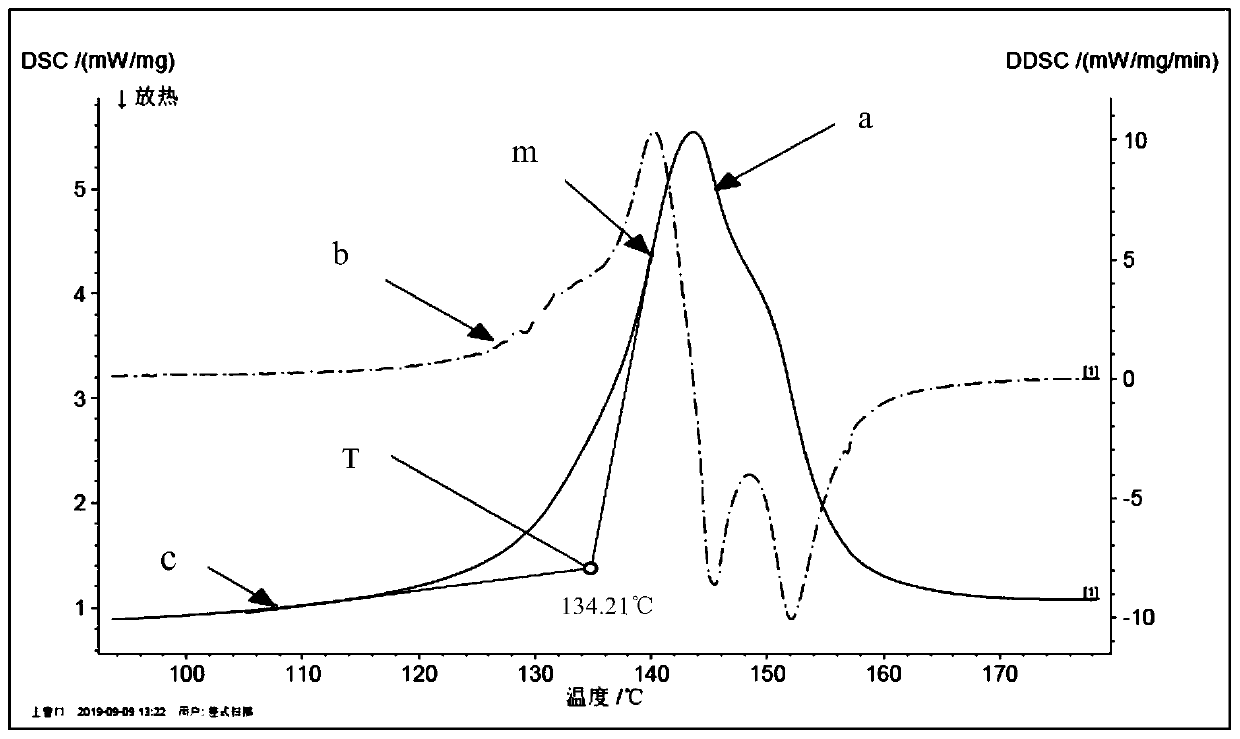

[0024] A method for measuring the closed cell temperature of a diaphragm. During the temperature rise process, the heat flow difference between the diaphragm sample and the reference object is measured to characterize all physical and chemical changes related to thermal effects, and the DSC curve of the diaphragm sample is calculated. The first-order derivative forms a first-order derivative curve. The temperature corresponding to the highest point of the first-order derivative curve is the fastest heat absorption temperature. At this time, the heated contact area of the diaphragm is the largest, and the diaphragm is completely closed, so this temperature is the complete closed-cell temperature of the diaphragm.

Embodiment 2

[0026] The following uses a differential scanning calorimeter to specifically describe the measurement steps of the closed cell temperature of the diaphragm:

[0027] Step 1. Sample pretreatment: place a diaphragm in an environment with a temperature of 23±2°C and a relative humidity of 50±10% for no less than 4 hours.

[0028] Step 2. Sampling and weighing: Use scissors to cut a piece of diaphragm sample from the geometric center of the diaphragm, use a puncher to punch out a disc with a diameter slightly smaller than the inner diameter of the sample crucible, and take about 5-10 mg of diaphragm sample, accurately to 0.1 mg, spread the diaphragm sample in the sample crucible, cover it, and pierce the center of the cover with a steel needle; weigh the weight of the sample crucible after placing the diaphragm sample, accurate to 0.01 mg.

[0029] Step 3. Temperature scan:

[0030] 3.1 At room temperature, put the sample crucible and reference crucible into the sample chamber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com