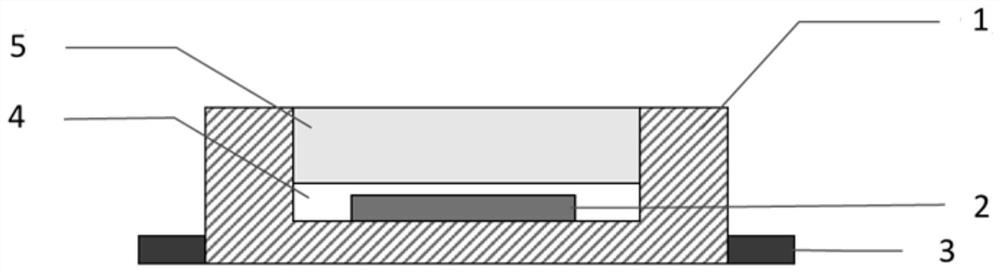

an optical device

An optical device and visible light technology, applied in the field of infrared optics, can solve the problems such as the difficulty of controllable adjustment of white light power and the difficulty of perfectly presenting visual effects, and achieve the effects of strong anti-interference ability, reduced packaging costs, and soft visual effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

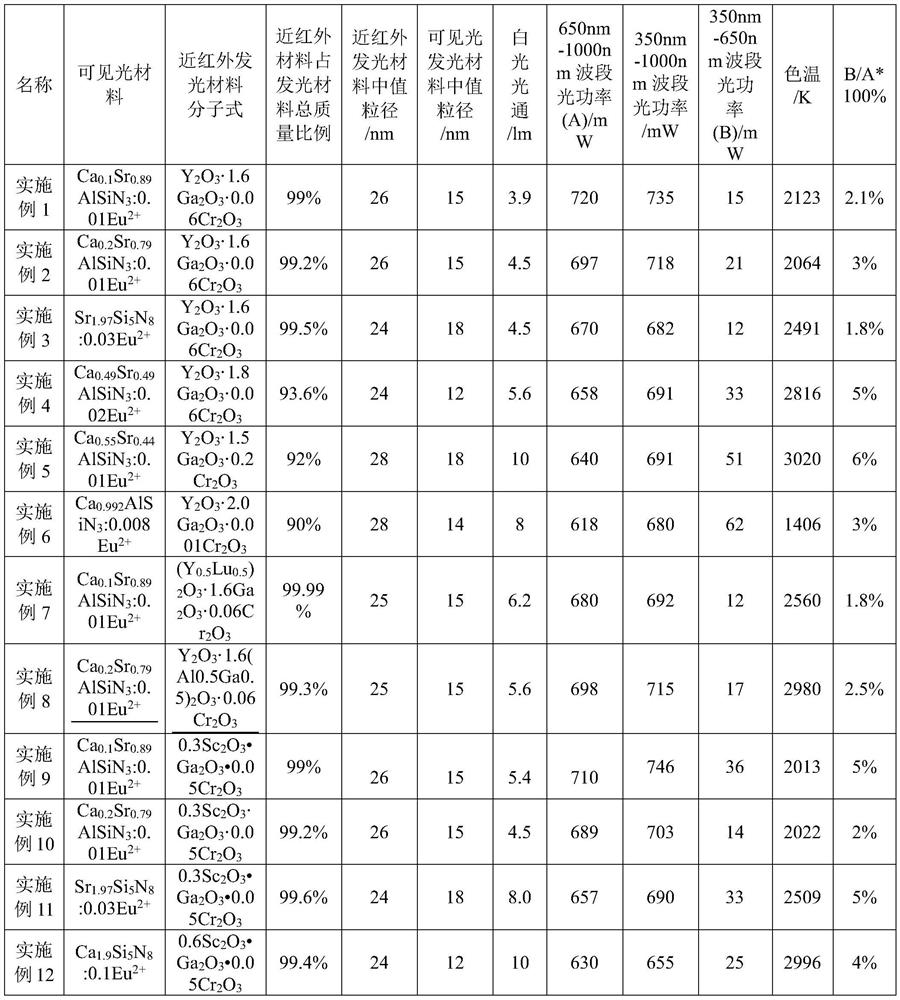

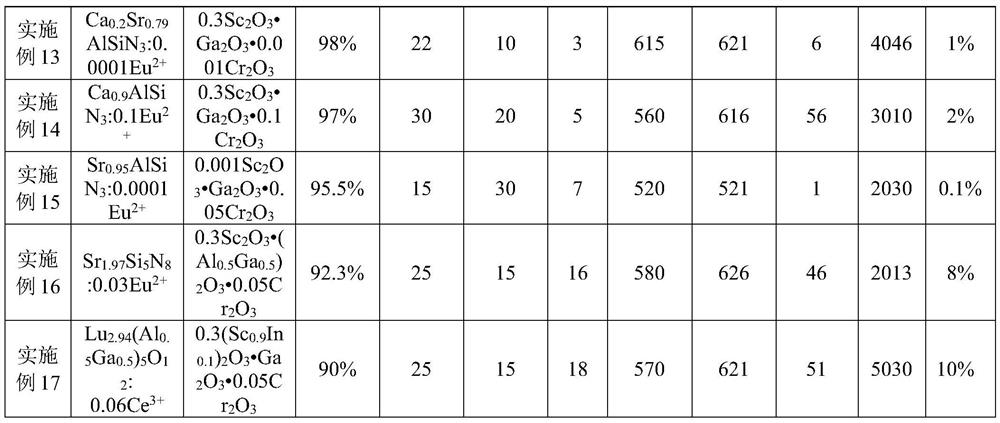

[0056] An optical device, the components of which are blue LED chips with a wavelength of 440nm and a molecular formula of Ca 0.1 Sr 0.89 AlSiN 3 :0.01Eu 2+ Visible light luminescent material, the molecular formula is Y 2 o 3 1.6Ga 2 o 3 0.06Cr 2 o 3 The near-infrared luminescent material; wherein the near-infrared luminescent material accounts for 99% of the total mass of the luminescent material, and the D50 particle size of the near-infrared luminescent material is 26 μm; the D50 particle size of the visible light luminescent material is 15 μm. Mix the visible light luminescent material and silica gel evenly in the present invention, stir and defoam to obtain the visible light fluorescence conversion layer mixture, and cover the mixture on the surface of the LED chip layer by coating, wherein the visible light luminescent material is on the light emitting surface of the LED chip The coating mass in the vertical direction accounts for 20% of the total mass of the vis...

Embodiment 4

[0059] An optical device, the components of which are blue LED chips with a wavelength of 460nm and a molecular formula of Ca 0.49 Sr 0.49 AlSiN 3 :0.02Eu 2+ Visible light luminescent material, the molecular formula is Y 2 o 3 1.8Ga 2 o 3 0.06Cr 2 o 3 The near-infrared luminescent material; wherein the near-infrared luminescent material accounts for 93.6% of the total mass of the luminescent material, and the D50 particle size of the near-infrared luminescent material is 24 μm; the D50 particle size of the visible light luminescent material is 12 μm. Mix the visible light luminescent material and silica gel evenly in the present invention, stir and defoam to obtain the visible light fluorescence conversion layer mixture, and cover the mixture on the surface of the LED chip layer by dispensing, wherein the visible light luminescent material is on the light emitting surface of the LED chip The coating mass in the vertical direction accounts for 10% of the total mass of t...

Embodiment 7

[0062] An optical device, the components of which are blue LED chips with a wavelength of 420nm and a molecular formula of Ca 0.1 Sr 0.89 AlSiN 3 :0.01Eu 2+ Visible light luminescent material, the molecular formula is (Y 0.5 Lu 0.5 ) 2o 3 1.6Ga 2 o 3 0.06Cr 2 o 3 The near-infrared luminescent material; wherein the near-infrared luminescent material accounts for 99.99% of the total mass of the luminescent material, and the D50 particle size of the near-infrared luminescent material is 25 μm; the D50 particle size of the visible light luminescent material is 15 μm. Mix the visible light luminescent material and silica gel evenly in the present invention, stir and defoam to obtain the visible light fluorescence conversion layer mixture, and cover the mixture on the surface of the LED chip layer by dispensing, wherein the visible light luminescent material is on the light emitting surface of the LED chip The coating mass in the vertical direction accounts for 10% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com