A kind of sinusoidal stepped horn-shaped sound transducer and energy conversion method

An acoustic transducer and horn-shaped technology, which is applied in the field of sinusoidal stepped horn-shaped acoustic transducers, can solve the problems of low voltage emission response, large size, and large disc diameter, so as to avoid sound field destructive interference and voltage emission response. The effect of increasing and reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will now be further described in conjunction with the drawings and embodiments, but the present invention is not limited to the following implementation situations.

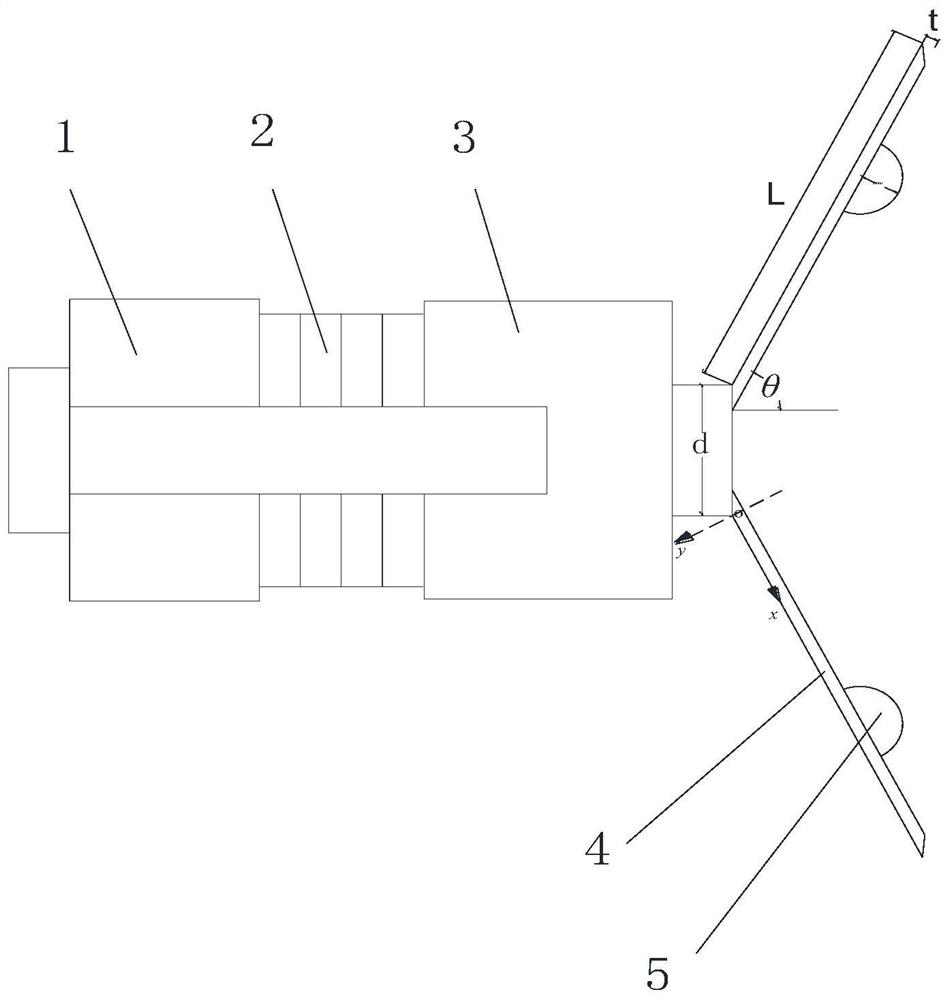

[0024] see figure 1 , the sinusoidal stepped horn-shaped acoustic transducer of the present invention comprises the rear cover plate 1, piezoelectric ceramic stack 2, front cover plate 3 and horn 4 that are arranged on the same axis in sequence, the rear cover plate 1, front cover plate 3 and horn 4 The material is 45# steel, the rear cover 1, the piezoelectric ceramic stack 2 and the front cover 3 are fixed by bolts passing through the central axis, the bottom end of the horn 4 is fixed on the front end of the front cover 3, and the length of the horn 4 is L 30~100mm, the opening angle θ is 30°~75°, the wall thickness t is 1.8~5.4mm, and the working frequency is 15~30kHz. An inwardly protruding circular sinusoidal step 5 is also provided on the inner side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com