Cleaning system of solar power generating device

A technology of power generation device and cleaning system, which is applied to the cleaning method using tools, photovoltaic power generation, cleaning methods and appliances, etc., which can solve the problems affecting the quality of ash removal and achieve the effect of ensuring the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

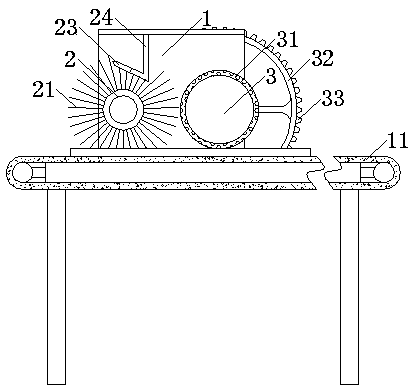

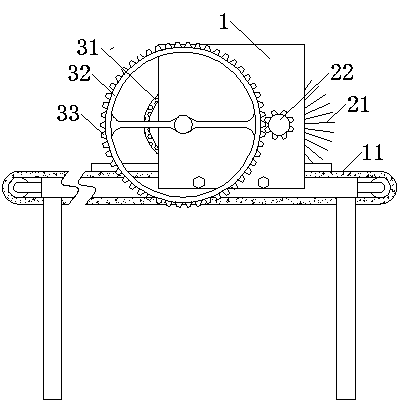

[0014] Such as Figures 1 to 2 As shown, a cleaning system for a solar power generation device includes a support plate 1, and the support plate 1 is set as two front and rear parallel upwards, and the two support plates 1 are fixed on the front and rear ends of the middle workbench, and the support plate 1 and the The worktables are connected by bolts, which is convenient for installation. A conveyor belt 11 is installed on the workbench. The conveyor belt 11 is driven by two left and right conveyor rollers. Connected by a crossbar.

[0015] Between the left sides of the two support plates 1, a drum 2 with soft bristles 21 is connected in rotation through two front and rear left rotation shafts; On the roller 3 at the top of the solar panel on the conveyor belt 11, the circumference of the roller 3 is bonded with a non-slip rubber layer 31 to increase friction and protect the solar panel. Connected, the transmission mechanism includes a gear 22 fixed on the rear end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com