Thickening method of petroleum and natural gas drill rod formed by thickening and extrusion

A technology of oil and gas extrusion molding, which is applied in the direction of metal extrusion control equipment, metal extrusion, metal extrusion dies, etc., can solve the problem that the size and shape are difficult to control, it is difficult to ensure the smoothness of the inner transition zone, and the drill pipe fatigue Low service life and other problems, to achieve long length, improve drill pipe performance and reduce non-production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

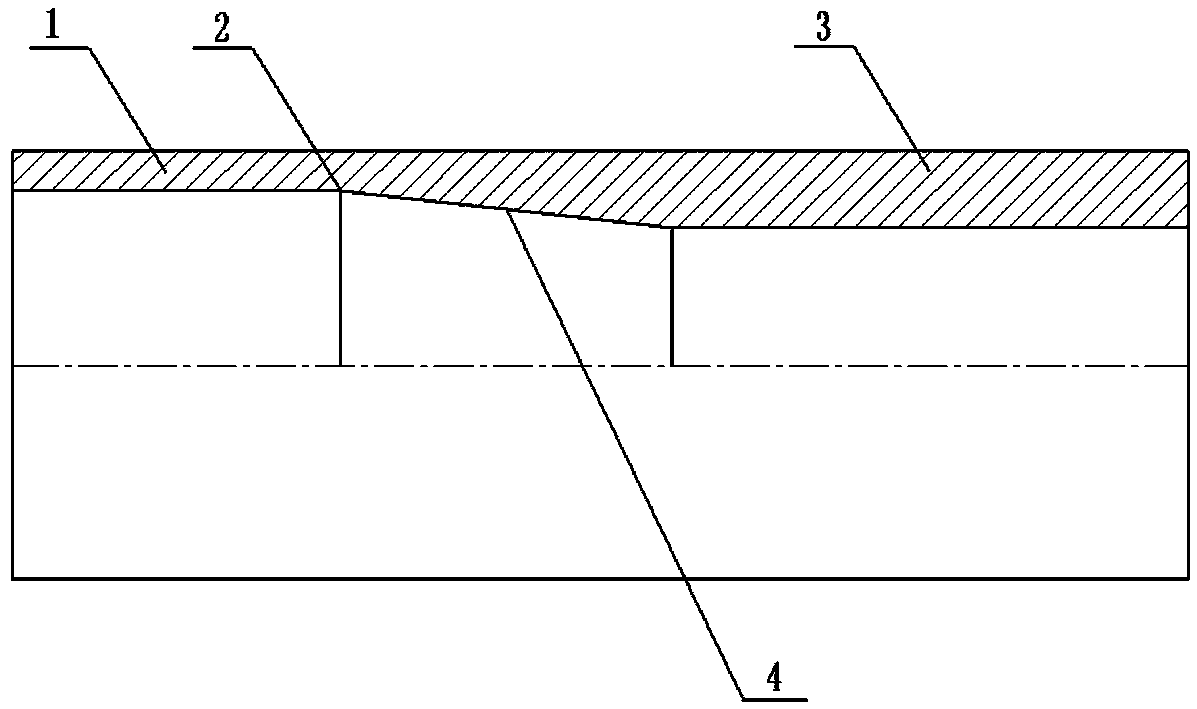

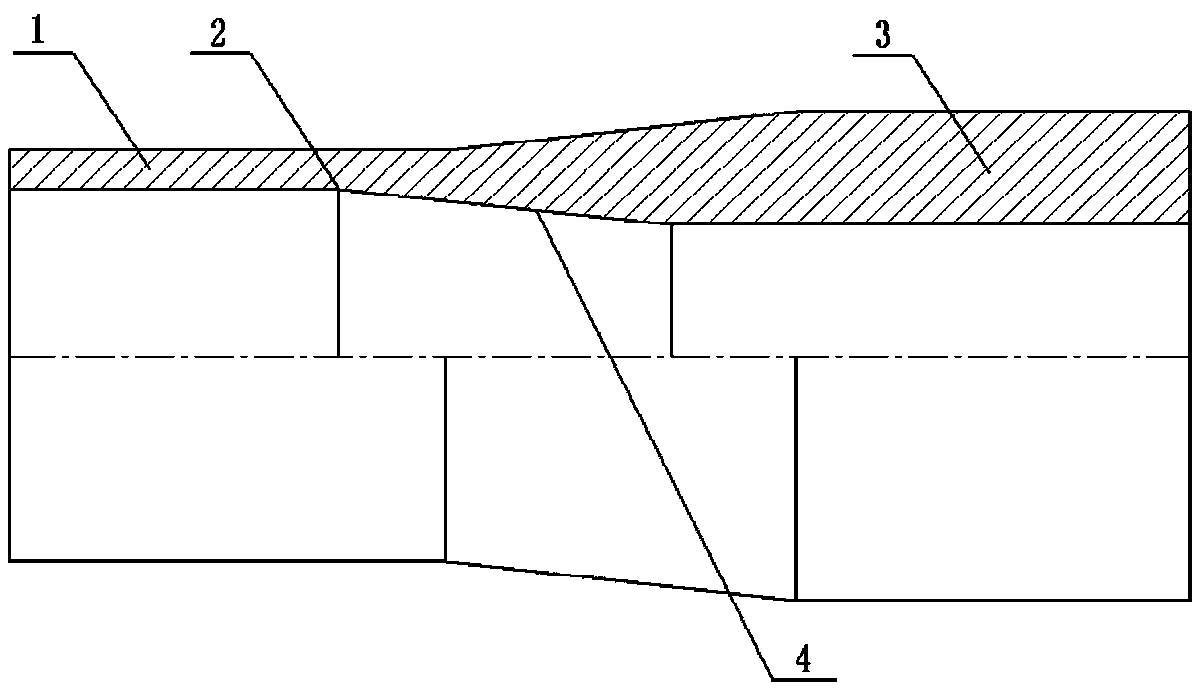

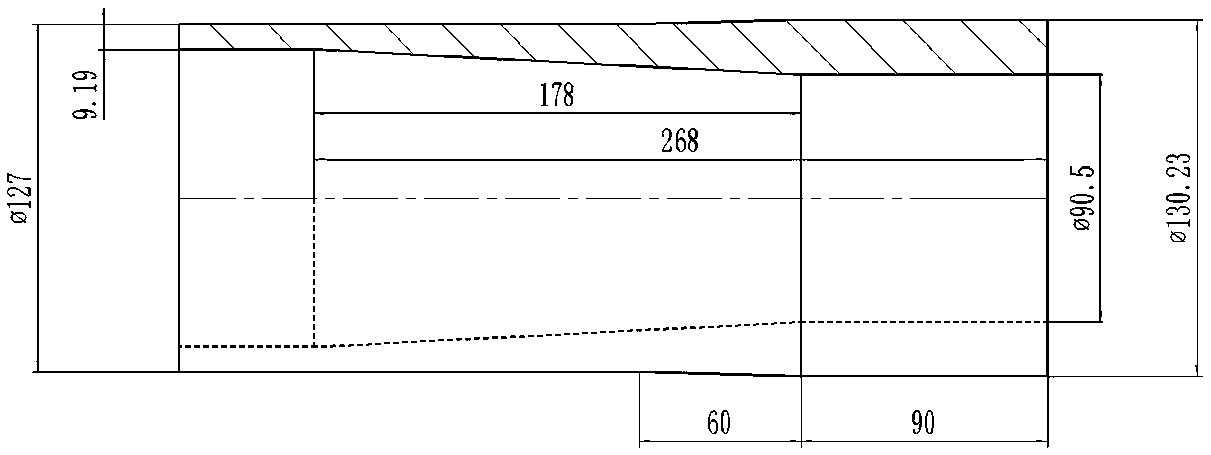

[0067] Take the most widely used drill pipe of 5 inches, wall thickness 9.19mm, S135 steel grade, IEU thickening form, and material as 4124M as an example, the oil and gas drill pipe thickening method combined with extrusion molding of the present invention can be The inner transition zone at the thickened end is more than 178mm. The implementation process is described in detail below.

[0068] The finished picture of the thickened end of this specification (that is, the picture after the thickened end is processed) is shown in image 3 . Except for the 178mm length of the thickened inner transition zone, which is far greater than the 76.2mm length specified by API 5DP, the rest of the dimensions meet the requirements of API 5DP.

[0069] The first step is the preparation before thickening and extrusion.

[0070] According to the finished product size of the thickened end of the drill pipe, the size of the cold forged part of the thickened end, the size of the cold blank be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com