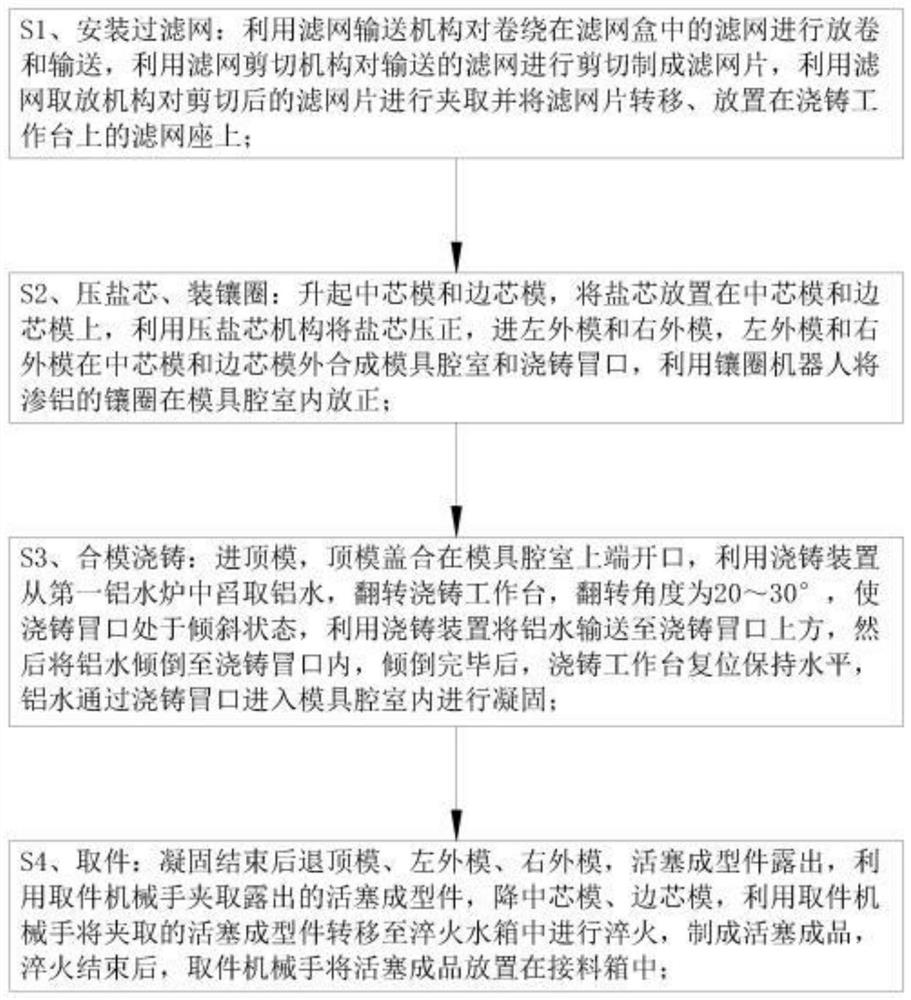

A piston automatic casting process

A piston and automatic technology, which is applied to casting molds, casting mold components, manufacturing tools, etc., can solve problems such as high risk, splashing of aluminum water, and safety of aluminum water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

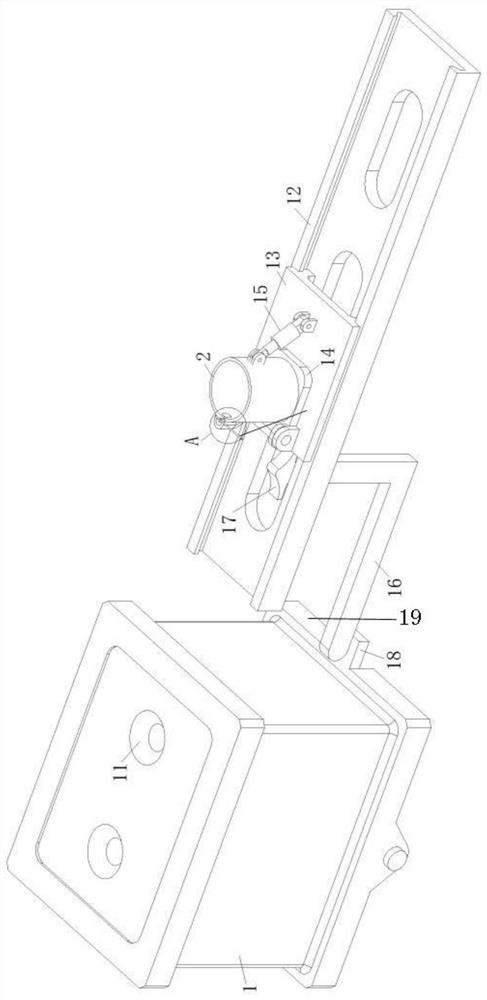

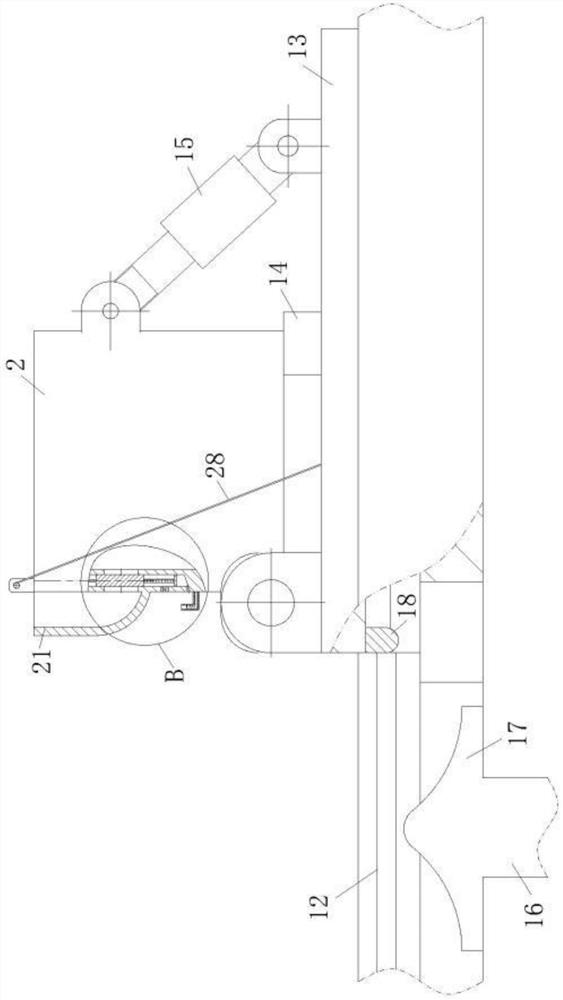

[0032] As an embodiment of the present invention, the wedge 17 is an upwardly protruding arc structure, and the arc wedge 17 reduces the impact on the movement of the casting trolley 13, and reduces the overflow of aluminum water from the aluminum pool 2; through the arc The wedge 17 makes the casting trolley 13 slowly and steadily push the wedge 17 and the ejector rod 16 to move downward during the movement, thereby reducing the impact of the wedge 17 on the speed of the casting trolley 13, reducing the sudden change in the speed of the casting trolley 13, and reducing the aluminum The overflow of the aluminum water in the pool 2 further increases the utilization rate of the aluminum water and increases the casting efficiency of the piston.

[0033] As an embodiment of the present invention, the communication hole 22 is lower than the liquid level of the aluminum water in the aluminum water pool 2; a chute 23 is provided at a position corresponding to the communication hole 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com