Continuous biological nitrogen and phosphorus removal recovery system and continuous biological nitrogen and phosphorus removal recovery technology

A technology for biological denitrification and phosphorus recovery, applied in sustainable biological treatment, biological water/sewage treatment, aerobic and anaerobic process treatment, etc. The problem of high cost, to achieve the effect of promoting enrichment, optimizing phosphorus removal performance, and improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

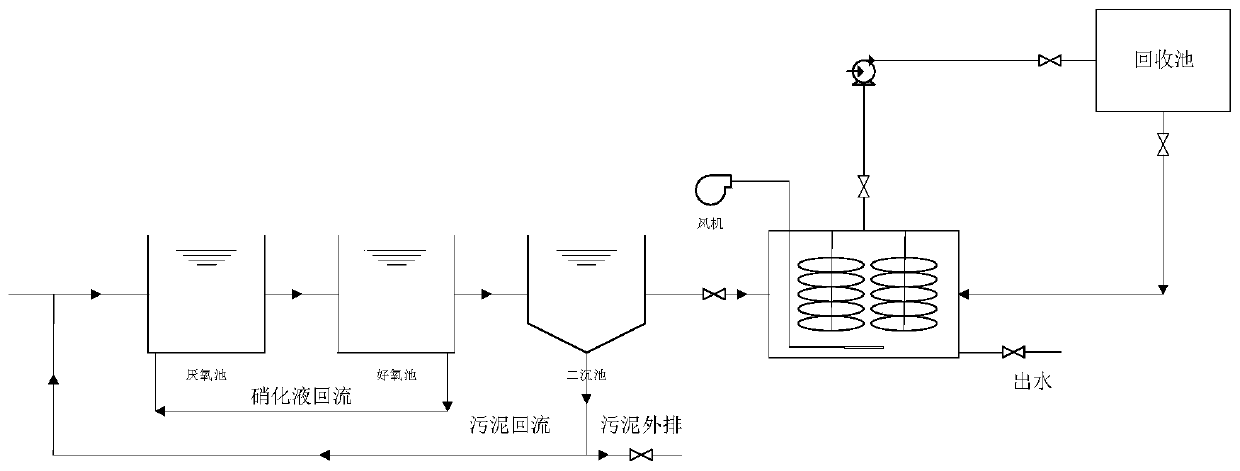

[0034] A continuous biological denitrification and phosphorus recovery process in this embodiment includes: A / O process (anaerobic tank, aerobic tank, secondary sedimentation tank) and biofilm process.

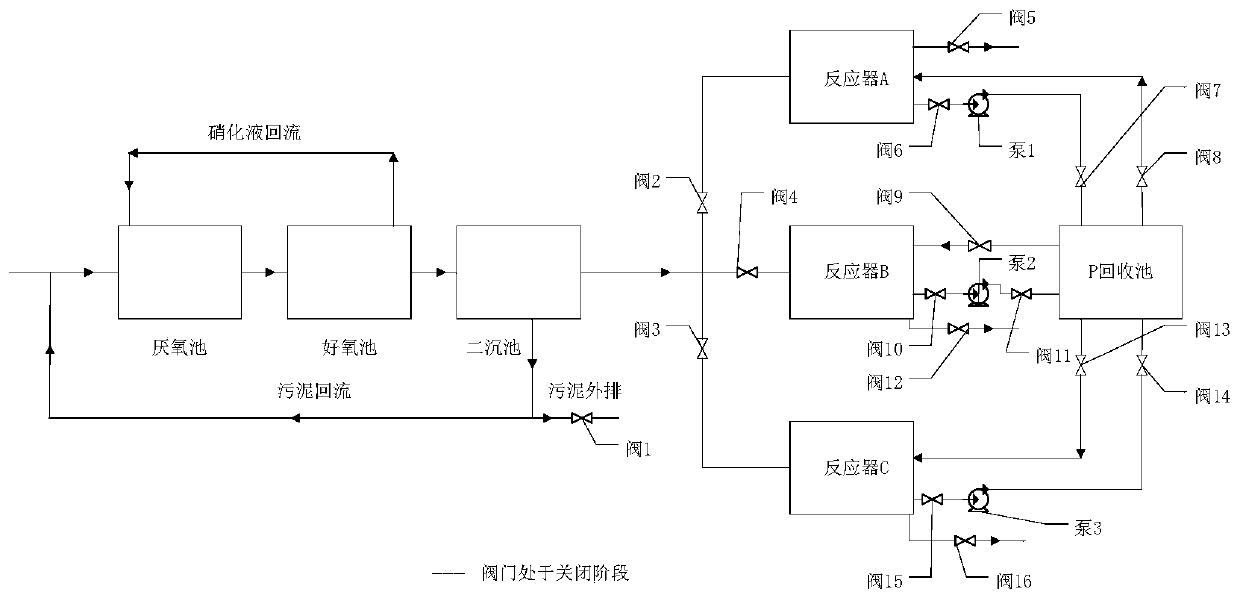

[0035] see figure 2 , in embodiment 1, there are at least 2 biofilm reactors running in parallel, below are example with 3 groups of identical biofilm reactors, have following three kinds of working conditions (dashed line represents valve is in closing stage).

[0036] image 3 The operating state of working condition 1 is shown, biofilm reactor A is in the water intake stage, biofilm reactor B is in the anaerobic recovery stage, and biofilm reactor C is in the aerobic stage. Open valve 2, phosphorus-containing wastewater from the A / O system enters biofilm reactor A equipped with aeration device; at the same time, biofilm reactor B is in the anaerobic recovery stage, open valve 9, due to gravity, The phosphorus-rich base solution in the high-level recovery tank flows direc...

Embodiment 2

[0042] The continuous biological denitrification and phosphorus recovery process of this embodiment includes: A / O process (anaerobic tank, aerobic tank, secondary sedimentation tank) and biofilm process.

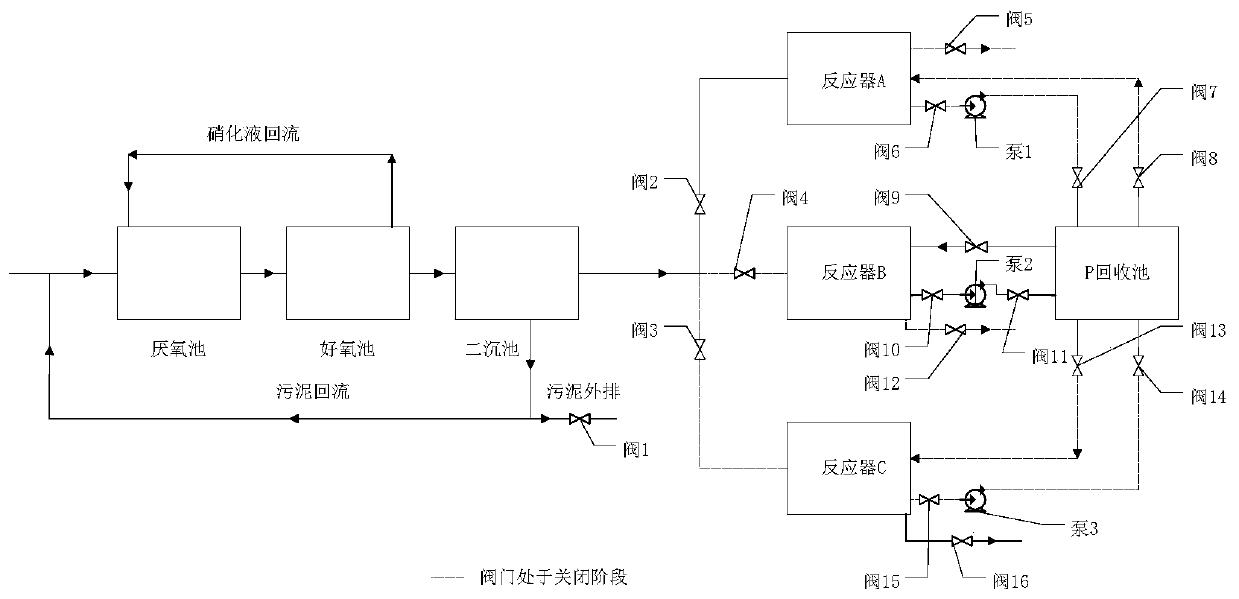

[0043] see Figure 7 As shown, in embodiment 2, there are at least 2 biofilm reactors running in parallel, and below are 3 groups of identical biofilm reactors as an example, with the following two working conditions (the dotted line represents the valve in the closed stage).

[0044] Figure 8 It shows the operating state of working condition 1, biofilm reactor A is in the water intake stage, biofilm reactor B is in the anaerobic recovery stage, and biofilm reactor C is in the aerobic stage. Open valve 2, the phosphorus-containing wastewater from the A / O system enters biofilm reactor A equipped with aeration device; at the same time, biofilm reactor B is in the anaerobic recovery stage, open valves 10 and 11, low-level The recovery solution in the recovery tank is pumped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com