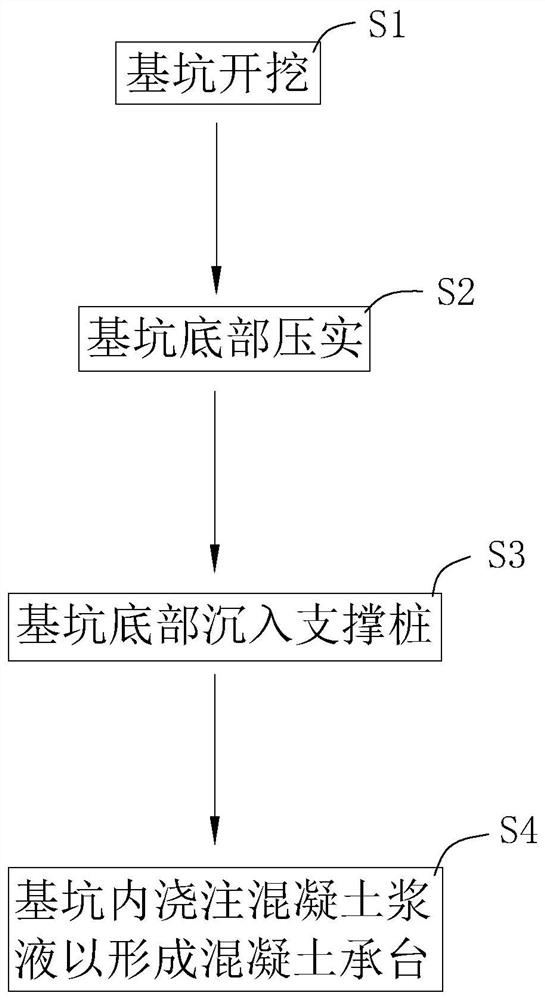

Construction method of municipal soft soil subgrade

A soft soil subgrade and construction method technology, applied in roads, roads, buildings, etc., can solve the problems of subgrade structural stability degradation, affecting road safety, easy bending and fracture, etc., to reduce fine lines, ensure road safety, The effect of not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

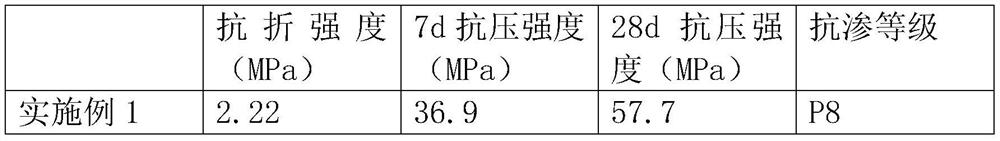

Embodiment 1

[0069] A kind of concrete slurry, the preparation method of concrete slurry is as follows:

[0070] a. Add 100kg of Portland cement, 90kg of water, and 11kg of water reducing agent into the stirring tank at a speed of 80r / min, and stir for 5min to form cement slurry;

[0071] b. Add 1 kg of tetraphenylmethane to the cement slurry, rotate at a speed of 80 r / min, and stir for 5 minutes to form a primary mixture;

[0072] c. Add 15kg of glass fiber and 50kg of residual mud to the primary mixture at a speed of 70r / min and stir for 8min to form a secondary mixture;

[0073] d. Add 200kg of coarse aggregate and 100kg of fine aggregate to the secondary mixture, and stir at a speed of 45r / min for 15 minutes to form a concrete slurry at a speed of 20r / min, and continue to stir until it is used up.

[0074] The length of the glass fiber is 2 cm.

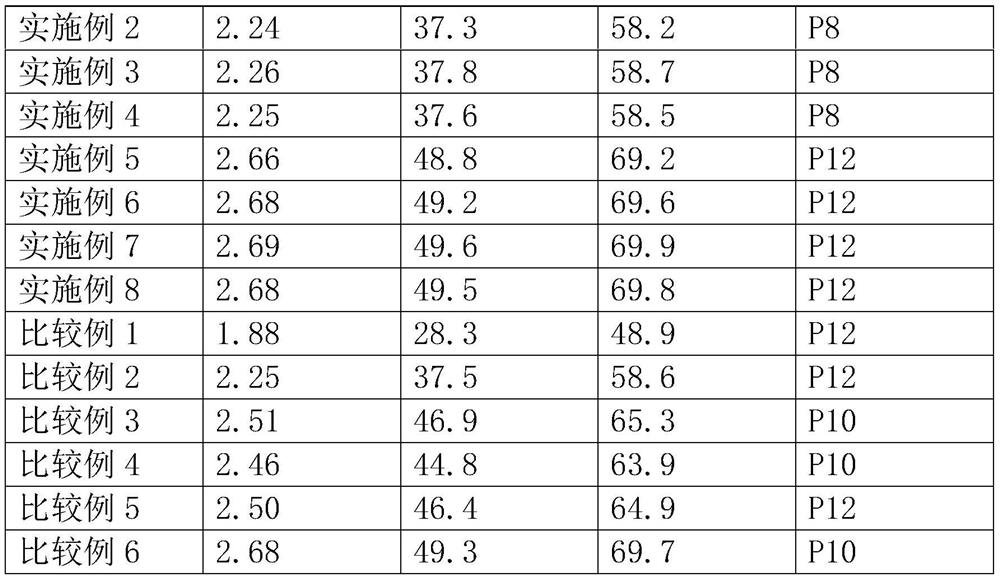

Embodiment 2

[0076] A kind of concrete slurry, the preparation method of concrete slurry is as follows:

[0077] a. Add 100kg of Portland cement, 100kg of water, and 10kg of water reducing agent into the stirring tank at a speed of 80r / min, and stir for 5min to form cement slurry;

[0078] b. Add 2kg of tetraphenylmethane into the cement slurry, rotate at a speed of 80r / min, and stir for 5min to form a primary mixture;

[0079] c. Add 22.5kg of glass fiber and 75kg of sludge to the primary mixture, and stir at a speed of 70r / min for 8 minutes to form a secondary mixture;

[0080] d. Add 225kg of coarse aggregate and 125kg of fine aggregate to the secondary mixture, and stir at a speed of 45r / min for 15 minutes to form a concrete slurry at a speed of 20r / min, and continue to stir until it is used up.

[0081] The length of the glass fiber is 3 cm.

Embodiment 3

[0083] A kind of concrete slurry, the preparation method of concrete slurry is as follows:

[0084] a. Add 100kg of Portland cement, 110kg of water, and 9kg of water reducing agent into the stirring tank at a speed of 80r / min, and stir for 5min to form cement slurry;

[0085] b. Add 3kg of tetraphenylmethane to the cement slurry, rotate at a speed of 80r / min, and stir for 5min to form a primary mixture;

[0086] c. Add 30kg of glass fiber and 100kg of residual sludge to the primary mixture at a speed of 70r / min and stir for 8min to form a secondary mixture;

[0087] d. Add 250kg of coarse aggregate and 150kg of fine aggregate to the secondary mixture, and stir at a speed of 45r / min for 15 minutes to form a concrete slurry at a speed of 20r / min, and continue to stir until it is used up.

[0088] The length of the glass fibers is 5 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com