Whole-stalk hemp fiber peeling device

A technology of hemp and fiber, applied in the field of agricultural machinery, can solve the problems of low work efficiency, unfavorable utilization of hemp bone, blank space, etc., and achieve the effects of reducing power consumption, improving the benefit of hemp farmers, and low unit energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

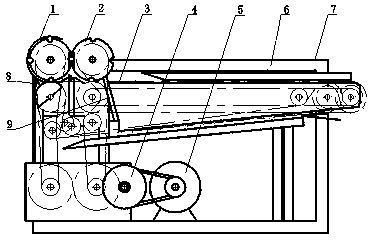

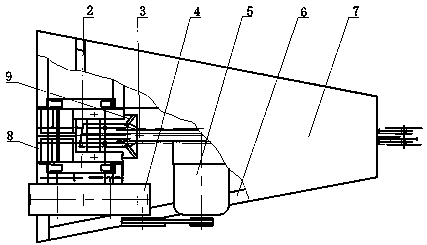

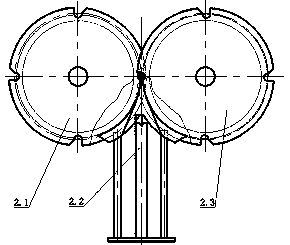

[0047] figure 1 , figure 2 It is a schematic diagram of the whole machine for bone-setting hemp fiber stripping equipment used for fixed operations on the field, including a safety cover 1, feeding and breaking mechanism 2, traction and separation mechanism 3, transmission mechanism 4, power (motor) 5, machine Frame 6, put hemp platform 7, horizontal hemp scraper 8, vertical hemp scraper 9.

[0048] The feeding and breaking mechanism 2 is arranged directly above the whole machine, the traction and separation mechanism 3 is located at the lower rear of the feeding and breaking mechanism 2, and the deceleration reverse gear box 4.2 of the power 5 and the transmission mechanism 4 is located at the lower right of the whole machine. The rotation speed of the traction sprocket of the traction separation mechanism 3 is twice that of the hemp feeding tray of the stalk breaking mechanism 2, and the number of feeding hemp openings on the hemp feeding tray is twice the number of workin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com