Clamping traction separation mechanism for whole-stalk jute and ambary hemp peeling machine

A separation mechanism and peeling machine technology, which is applied in fiber mechanical separation, mechanical treatment, textiles and papermaking, etc., can solve the problems of disordered hemp skin, high bone content in fresh skin, complicated operation, etc., and achieve the elimination of broken bones on the hemp skin , the effect of strong tensile ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

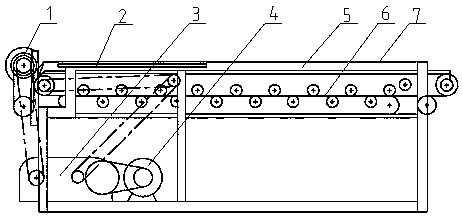

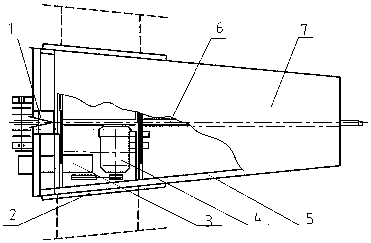

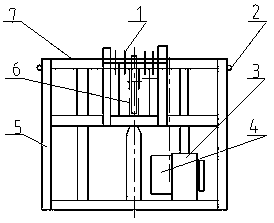

[0027] Machine such as figure 1 , figure 2 , image 3 As shown, it is composed of feeding and folding stalk mechanism 1, telescopic hemp releasing frame 2, transmission mechanism 3, power (electric motor is selected) 4, frame 5, clamping and pulling separation mechanism 6, and hemp releasing platform 7. The feeding stalk folding mechanism 1 is set directly above the machine, the clamping traction separation mechanism 6 is located at the lower back of the feeding stalk folding mechanism 1, the power (motor) 4 and the deceleration sub-box 3.2 of the transmission mechanism 3 are located at the lower right of the machine . Feeding the stalk folding mechanism cuts the middle part of the hemp stalk, breaks it, separates it, exposes the hemp bone at both ends, and sends it to the clamping traction separation mechanism 6, the upper clamping traction body 6.4 and the lower clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com