Cooling tower cooling system based on flow change and application thereof

A cooling system and flow change technology, applied in water shower coolers, heat exchange equipment, fixed duct components, etc., can solve the problems of high energy consumption and low degree of automation of fans, simplify operation, prolong service life, and reduce the number of units Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

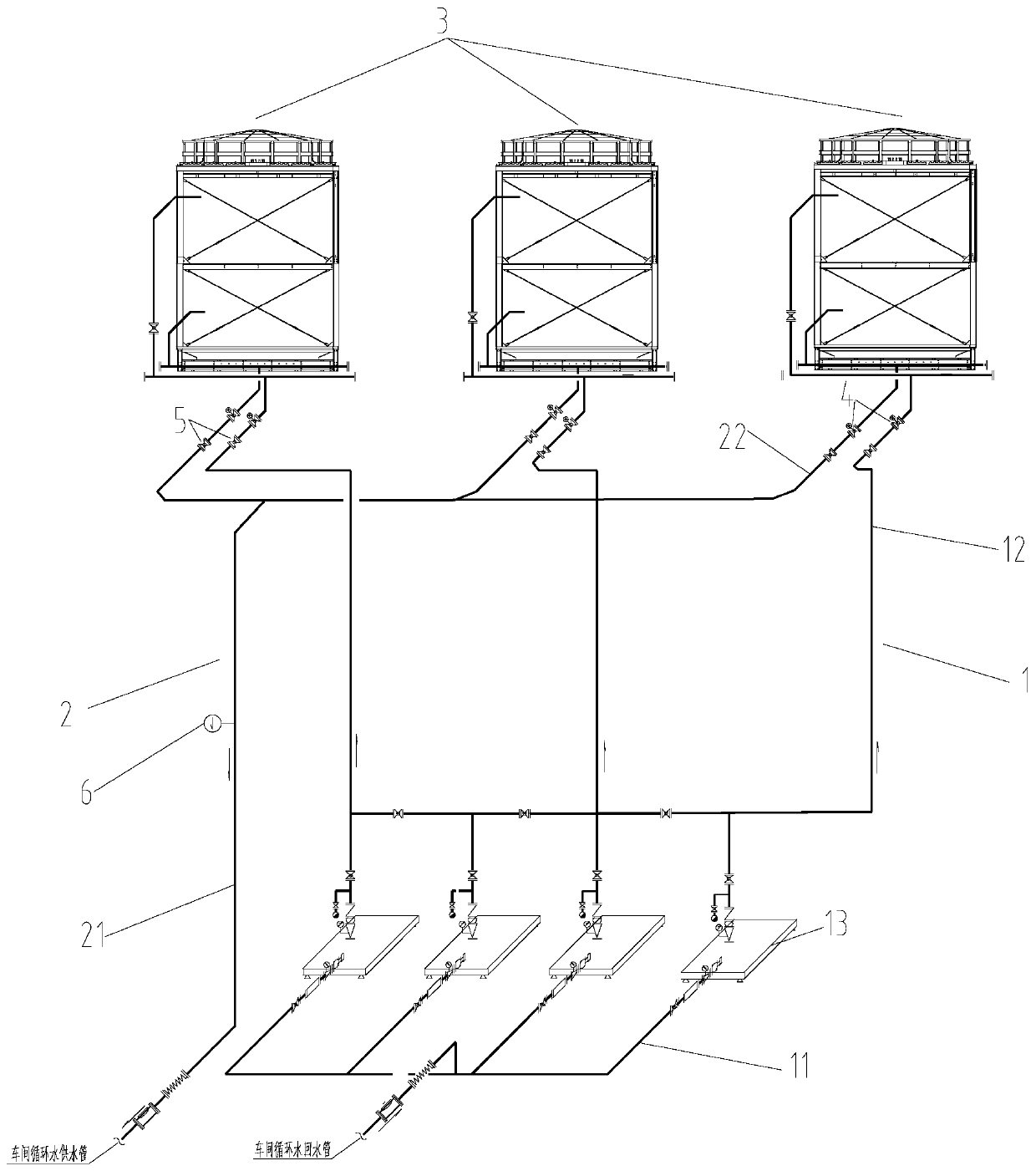

[0029] A cooling tower cooling system based on flow variation, such as figure 1 As shown, the cooling system of the cooling tower is connected with the circulating water of the workshop, including the water inlet pipeline 1, the closed cooling tower group and the water outlet pipeline 2 connected in sequence; the closed cooling tower group includes three closed cooling towers 3 connected in parallel , and the tower water flow ranges corresponding to the high energy efficiency intervals of the three closed cooling towers 3 are different. When in use, according to the size of the water flow to be treated, a matching closed cooling tower is selected for operation; and the fan in the closed cooling tower 3 The frequency of the motor is controlled using the wet bulb temperature. Such as figure 1 As shown by the middle arrow, when the system is working, the water passes through the main water inlet pipeline 11, the water pump 13, the water inlet branch pipeline 12, the closed cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com