High-voltage motor monitoring system based on optical fiber power supply and wireless communication

A high-voltage motor and optical fiber power supply technology, which is applied in the direction of motor generator testing, signal transmission system, measuring electricity, etc., can solve the problems of unsteady operation of testing equipment, laser production safety accidents, unstable optical power, etc., and reduce maintenance time and work risks, reduce the risk of link interruption, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Description will be made below in conjunction with the accompanying drawings.

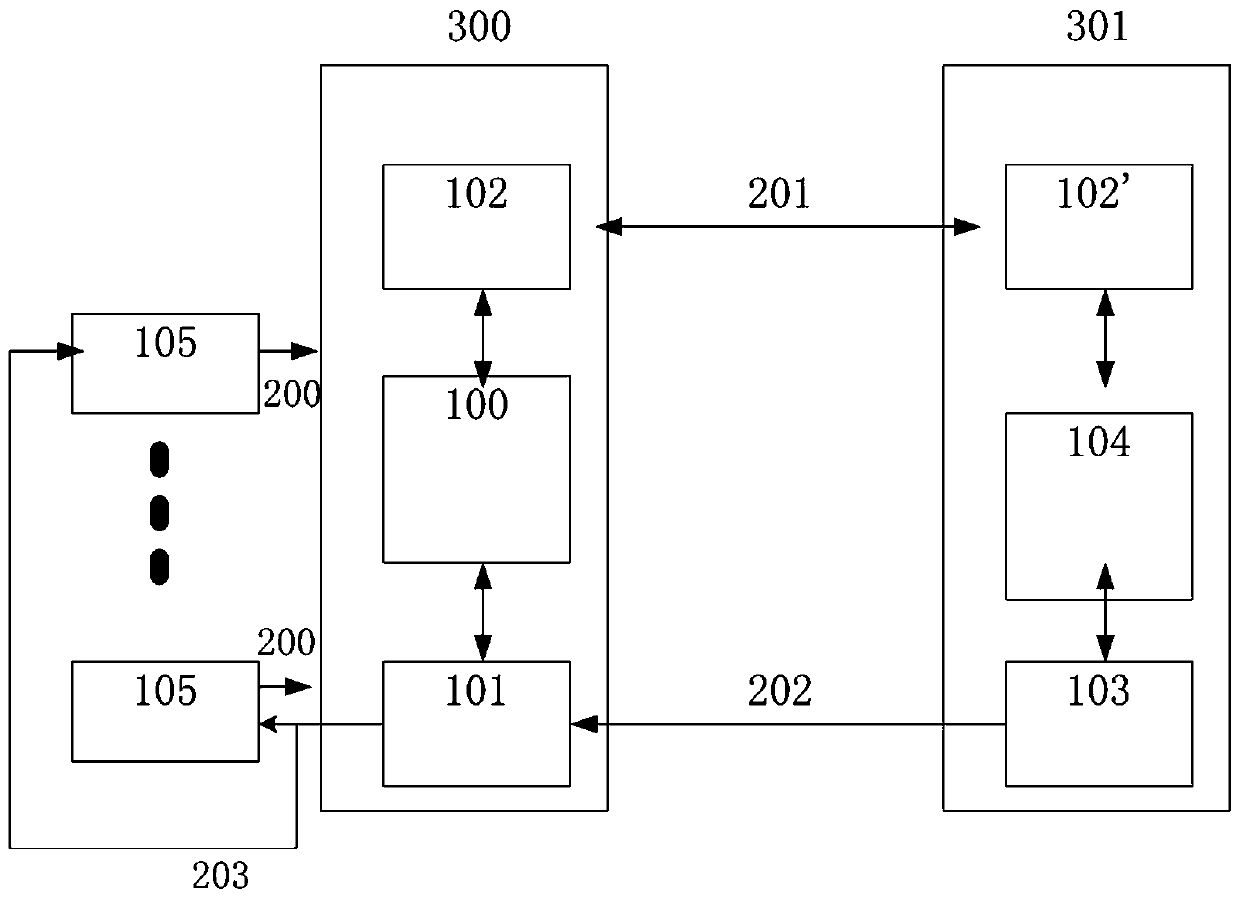

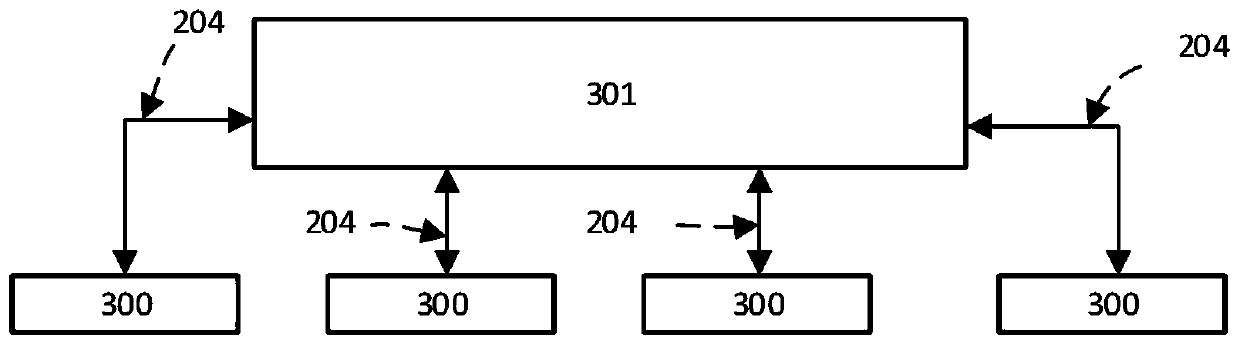

[0023] like figure 2 The high-voltage motor monitoring system includes a high-voltage motor management device and four high-voltage motor measurement devices (as other implementations, more high-voltage motor measurement devices or fewer high-voltage motor measurement devices can also be connected). A high-voltage motor management device 301 is connected to multiple high-voltage motor measuring devices 300 through a wireless data link and a power supply link 204, so as to monitor and manage multiple high-voltage motors.

[0024] like figure 1 As shown, the high-voltage motor measurement device includes a micro-power consumption MCU module 100 (such as MSP430 series microcontrollers, etc.), a power supply module 101, a wireless transceiver module 102, etc.; the high-voltage motor management device mainly includes a wireless transceiver module 102' (for measuring The wireless transceiver mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com