MEMS piezoelectric ultrasonic transducer with Helmholtz resonant cavity

An ultrasonic transducer, piezoelectric ultrasonic technology, applied in the direction of fluid using vibration, etc., can solve the problems of large device size and low resonance frequency, and achieve the effect of increasing the resonance frequency and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

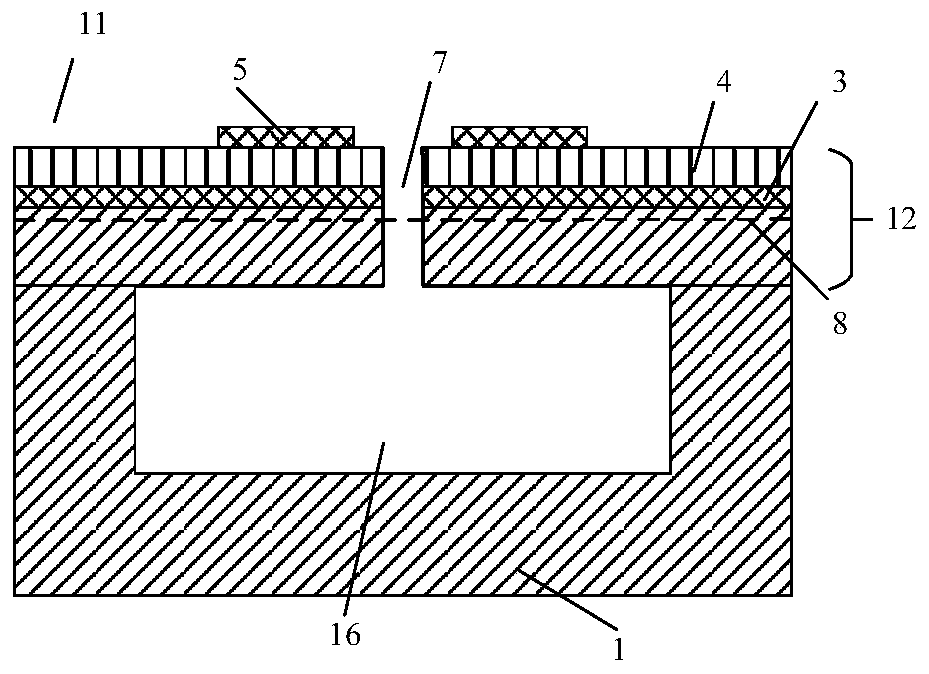

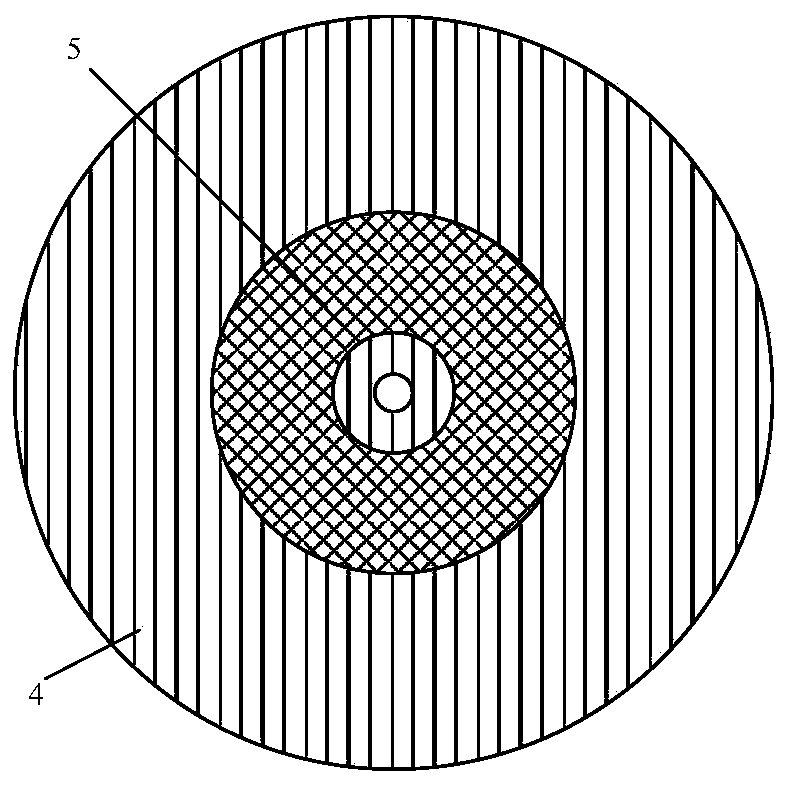

[0027] Such as figure 1 and figure 2 , the MEMS piezoelectric ultrasonic transducer includes a pMUT 11 and a Helmholtz resonant cavity 16 formed on the substrate layer 1 of silicon material, the resonant frequency of the Helmholtz resonant cavity 16 is consistent with the resonant frequency of the pMUT11, and the ultrasonic transducer The sound pressure of the sound wave emitted by the transducer will be greatly enhanced by the amplification of the Helmholtz resonant cavity 16, thereby improving the energy conversion efficiency of the ultrasonic transducer.

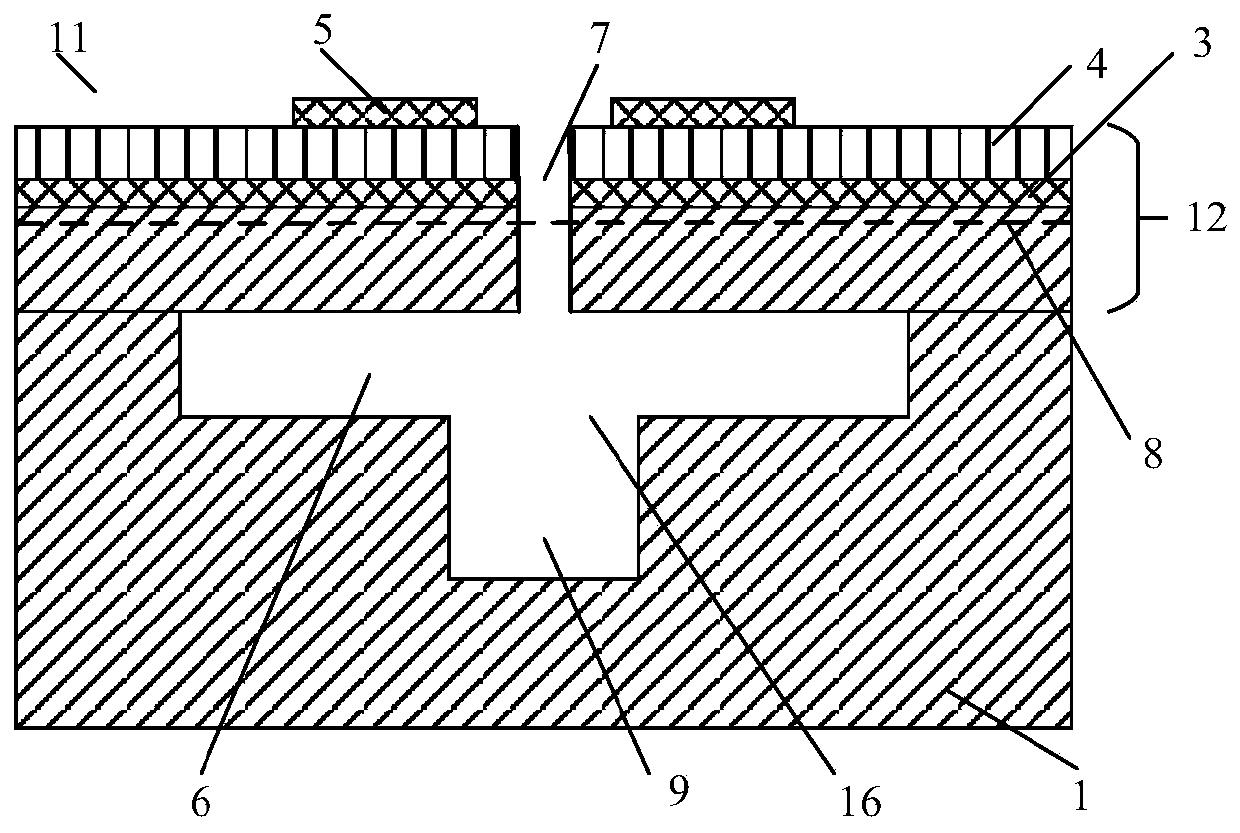

[0028] Such as Figure 3-6 , in order to reduce the volume of the Helmholtz resonator 16 to increase the resonance frequency of the Helmholtz resonator 16, the disclosure sets the height of the first cavity 6 of the Helmholtz resonator 16 to be greater than the MEMS pressure The maximum amplitude of the electro-ultrasonic transducer, and the middle part of the first cavity 6 sinks to form the second cavity 9 . In addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com