Double-spiral-groove combined type single-excitation three-dimensional curved surface ultrasonic-assisted turning device

A three-dimensional curved surface, ultrasonic-assisted technology, applied in the direction of turning equipment, turning equipment, metal processing equipment, etc., can solve the problems that ordinary turning cannot meet the required precision, cannot cut difficult-to-machine materials, and is difficult to meet practical requirements, etc. The vibration effect is obvious , easy control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

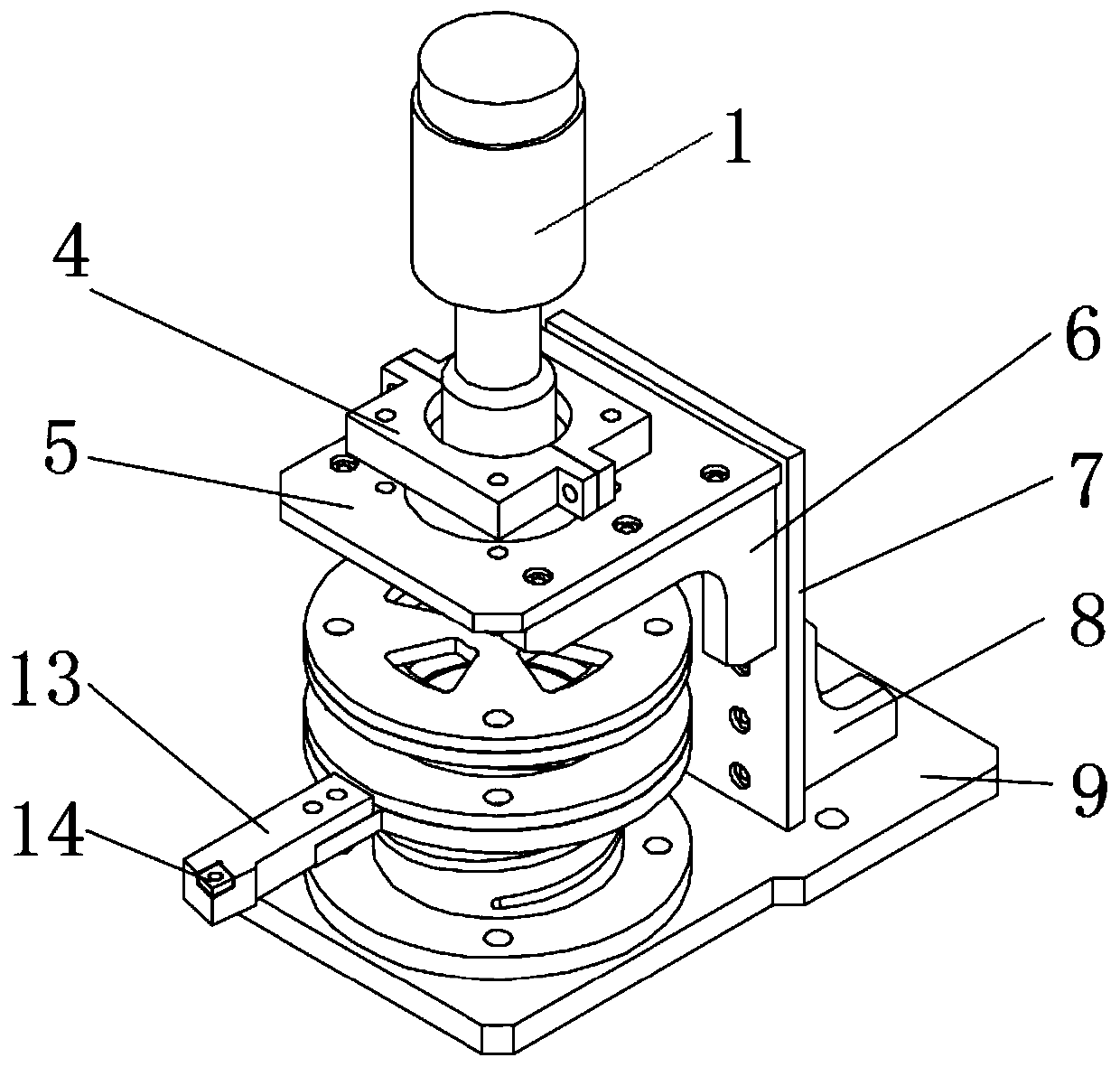

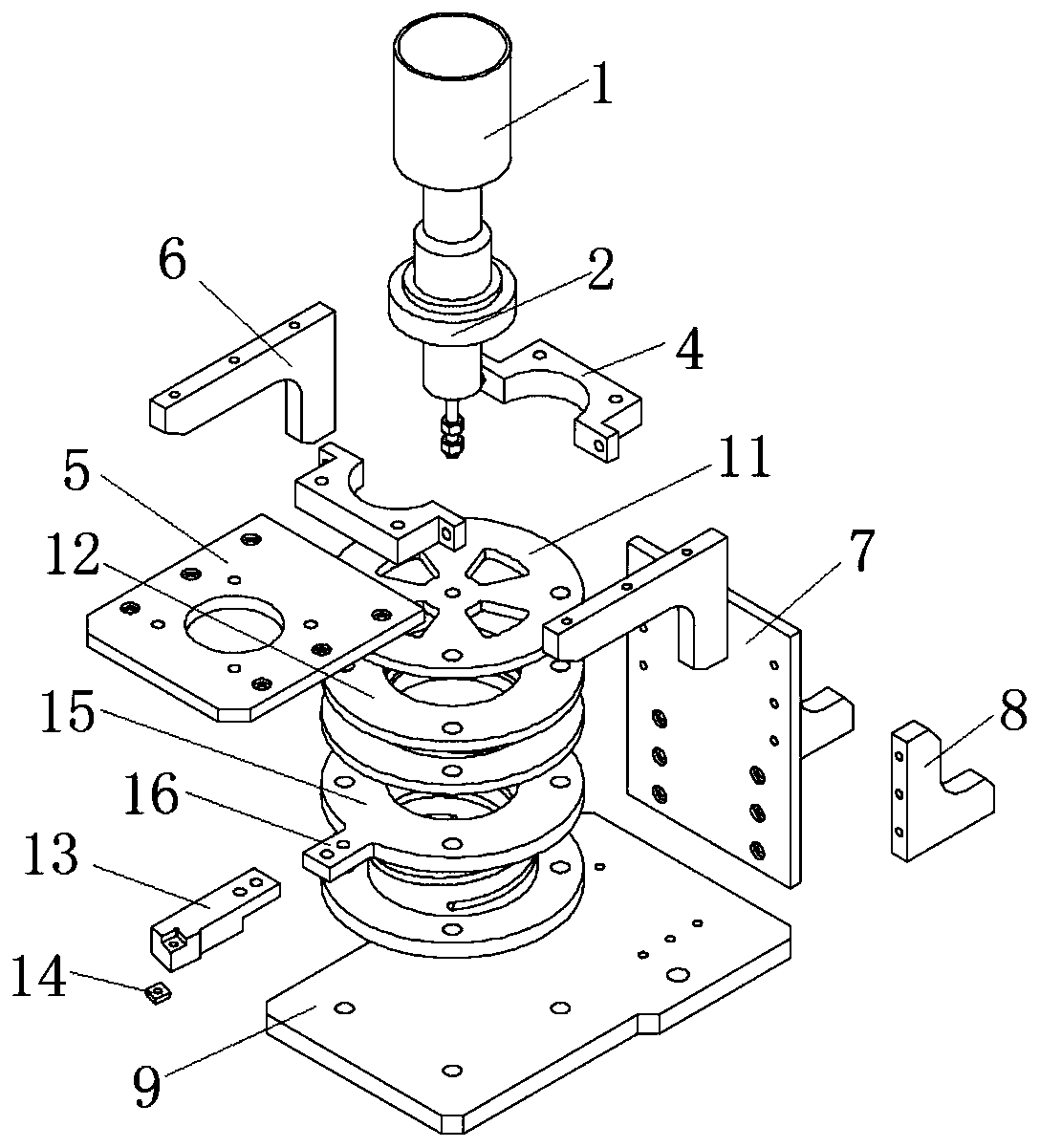

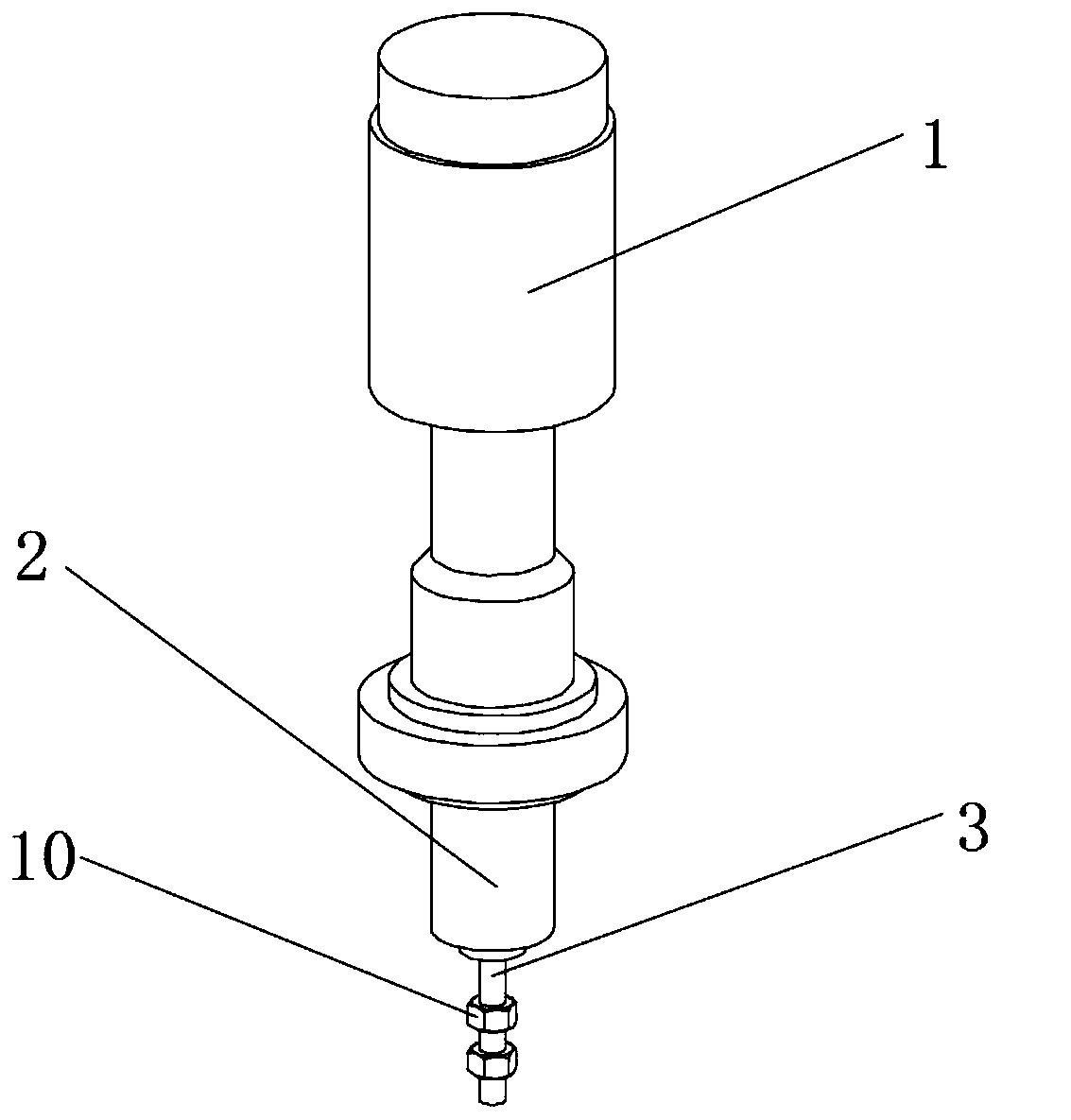

[0031] Such as figure 1 , figure 2 with Figure 5As shown, a double-helical groove combined single-excitation three-dimensional curved surface ultrasonic assisted turning device includes an ultrasonic excitation device, a double-helical groove combined pressing and twisting device and a fixing frame. The fixing frame adopts a symmetrical design to facilitate the installation of the entire device. Used on a lathe, the fixed frame includes a base 9, six light holes and six threaded holes are processed on the base 9, and the six threaded holes are arranged in three rows and two columns, and the upper surface of the base 9 is One end is connected to the lower side rib 8 through bolts and threaded holes, the lower side rib 8 is connected to one end of the vertical plate 7 through bolts, the other end of the vertical plate 7 is connected to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com