Laser self-fluxing brazing method of aluminum alloy-stainless steel dissimilar metals

A technology of dissimilar metals and brazing methods, applied in metal processing equipment, welding equipment, welding media, etc., can solve the problems of micro-cracks, thick intermetallic compounds, inability to guarantee the quality of welded joints, etc., to avoid micro-cracks and energy distribution. Uniform, high stability and operability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

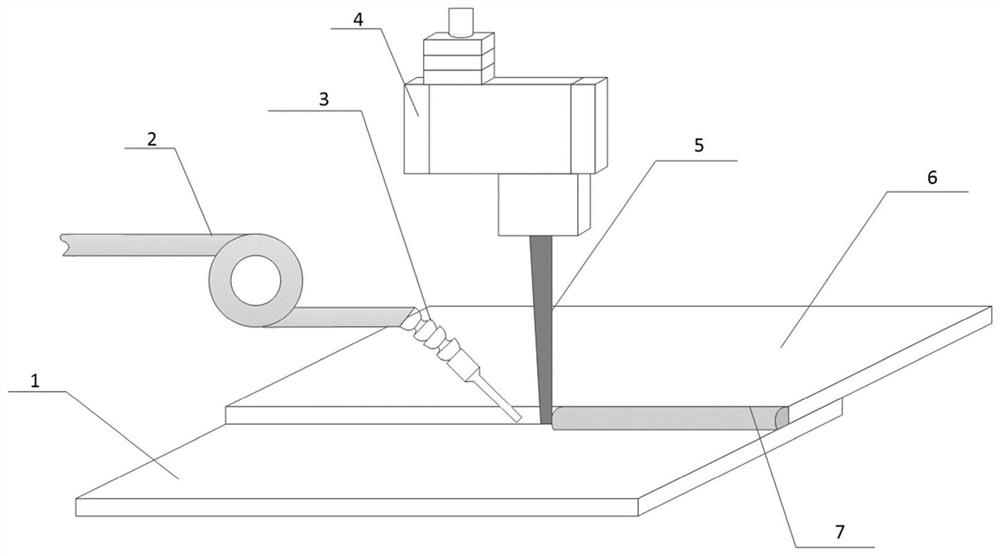

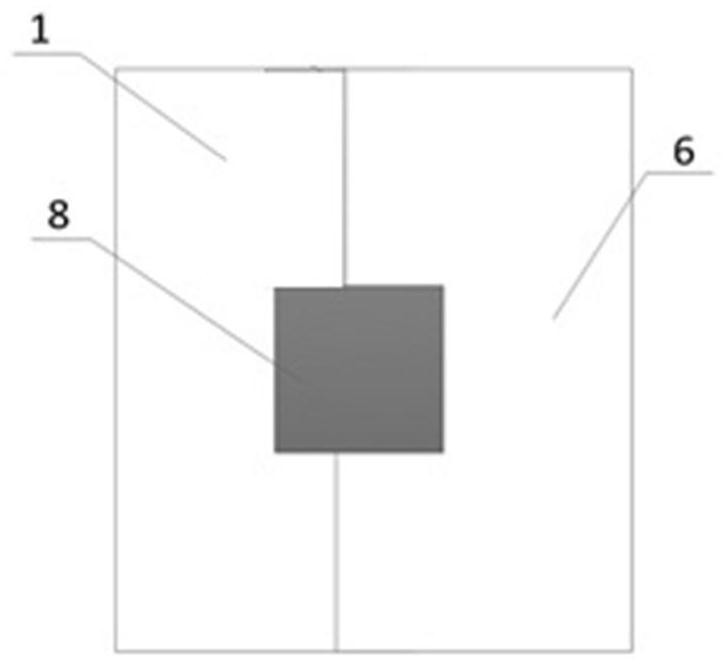

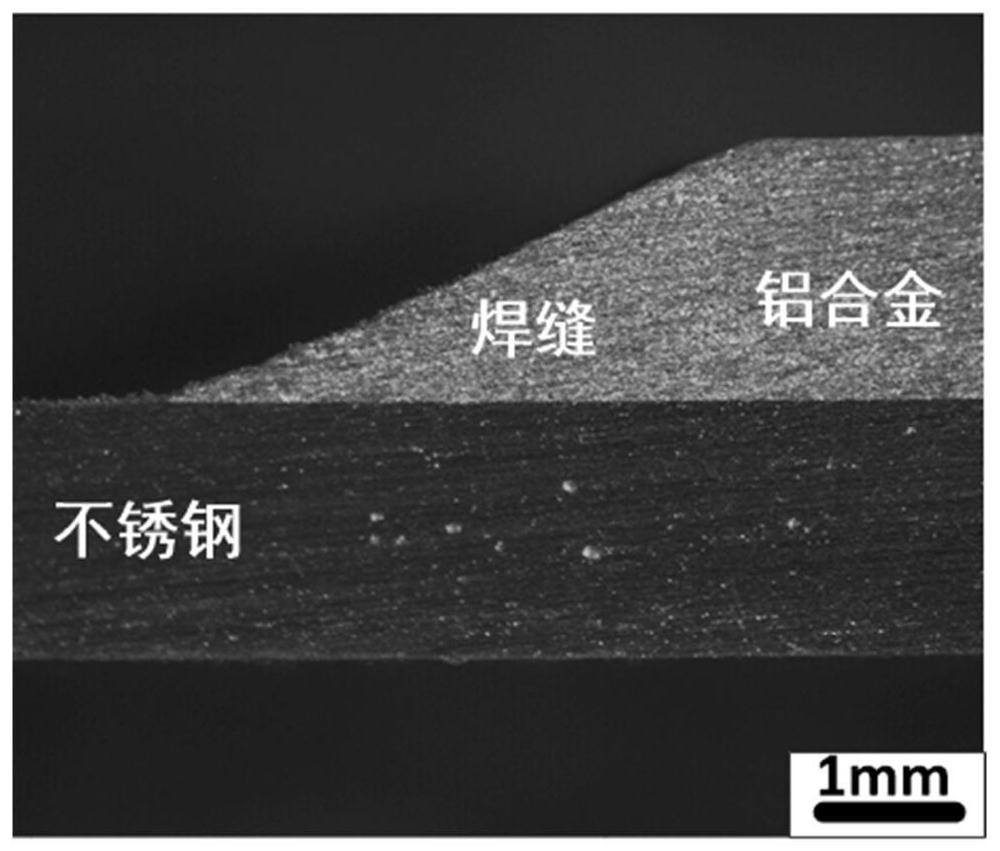

[0054] A laser self-fluxing brazing method of aluminum alloy-stainless steel dissimilar metals, the aluminum alloy plate to be welded is a 6061 aluminum alloy plate with a thickness of 1mm, the stainless steel plate to be welded is a 301L stainless steel plate with a thickness of 1mm, and the welding step as follows:

[0055] S1. Use 240-mesh sandpaper to grind the area to be welded on the aluminum alloy plate and stainless steel plate to be welded, then use acetone to scrub the area to be welded on the aluminum alloy plate, put the stainless steel plate in acetone for ultrasonic cleaning for 2 minutes, and use mass percentage 20%H 2 SO 4 The pickling solution composed of 15% HCl and 15% HCl is used to perform surface activation treatment on the area to be welded of the stainless steel plate at 45°C, and the surface activation treatment time is 60s;

[0056] S2, using the electroplating method, successively plate a Cu metal coating with a thickness of 8 μm and a Ni metal coa...

Embodiment 2

[0063] A laser self-fluxing brazing method of aluminum alloy-stainless steel dissimilar metals, the aluminum alloy plate to be welded is a 6063 aluminum alloy plate with a thickness of 2mm, the stainless steel plate to be welded is a 304 stainless steel plate with a thickness of 2mm, and the welding step as follows:

[0064] S1. Use 240-mesh sandpaper to grind the area to be welded on the aluminum alloy plate and stainless steel plate to be welded, then use acetone to scrub the area to be welded on the aluminum alloy plate, put the stainless steel plate in acetone for ultrasonic cleaning for 2 minutes, and use mass percentage 20%H 2 SO 4 The pickling solution composed of 15% HCl and 15% HCl is used to perform surface activation treatment on the area to be welded of the stainless steel plate at 55°C, and the surface activation treatment time is 60s;

[0065] S2, using electroplating, sequentially plate a Cu metal coating with a thickness of 11 μm and a Ni metal coating with a...

Embodiment 3

[0072] A laser self-fluxing brazing method of aluminum alloy-stainless steel dissimilar metals, the aluminum alloy plate to be welded is a 6063 aluminum alloy plate with a thickness of 4mm, the stainless steel plate to be welded is a 304 stainless steel plate with a thickness of 4mm, and the welding step as follows:

[0073] S1. Use 240-mesh sandpaper to grind the area to be welded on the aluminum alloy plate and stainless steel plate to be welded, then use acetone to scrub the area to be welded on the aluminum alloy plate, put the stainless steel plate in acetone for ultrasonic cleaning for 2 minutes, and use mass percentage 20%H 2 SO 4 The pickling solution composed of 15% HCl and 15% HCl is used to perform surface activation treatment on the area to be welded of the stainless steel plate at 60 °C, and the surface activation treatment time is 65s;

[0074] S2, using the electroplating method, sequentially plate a Cu metal coating with a thickness of 14 μm and a Ni metal co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com