Double-sided sand-blasting device for art glass acid corrosion etching

An art glass and sandblasting device technology, which is applied to used abrasive processing devices, abrasive jetting machine tools, abrasives, etc., can solve the problems of low sandblasting operation efficiency, shaking and increasing waste, increasing waste, etc., to reduce repeated spraying. Sand area, preventing glass from shaking and breaking easily, reducing the effect of manual use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

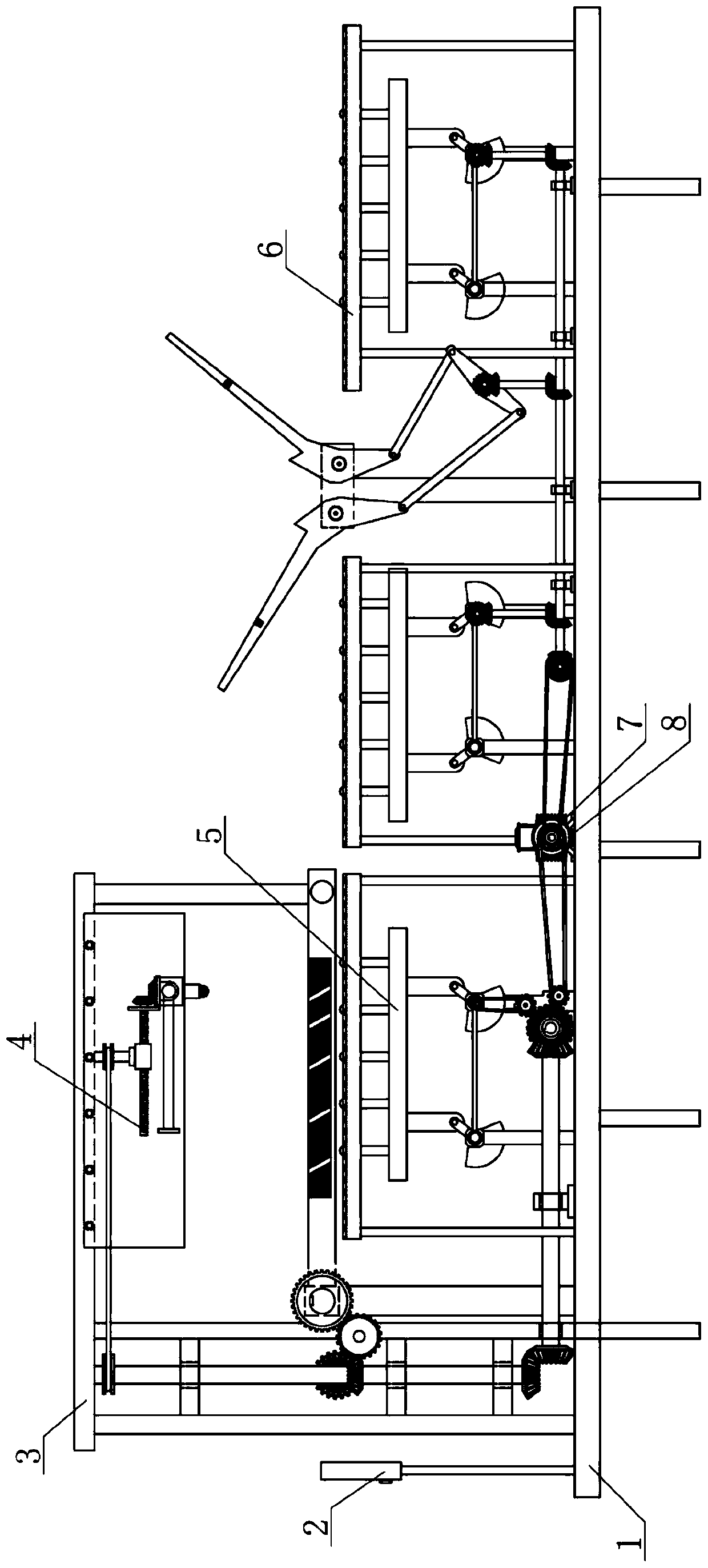

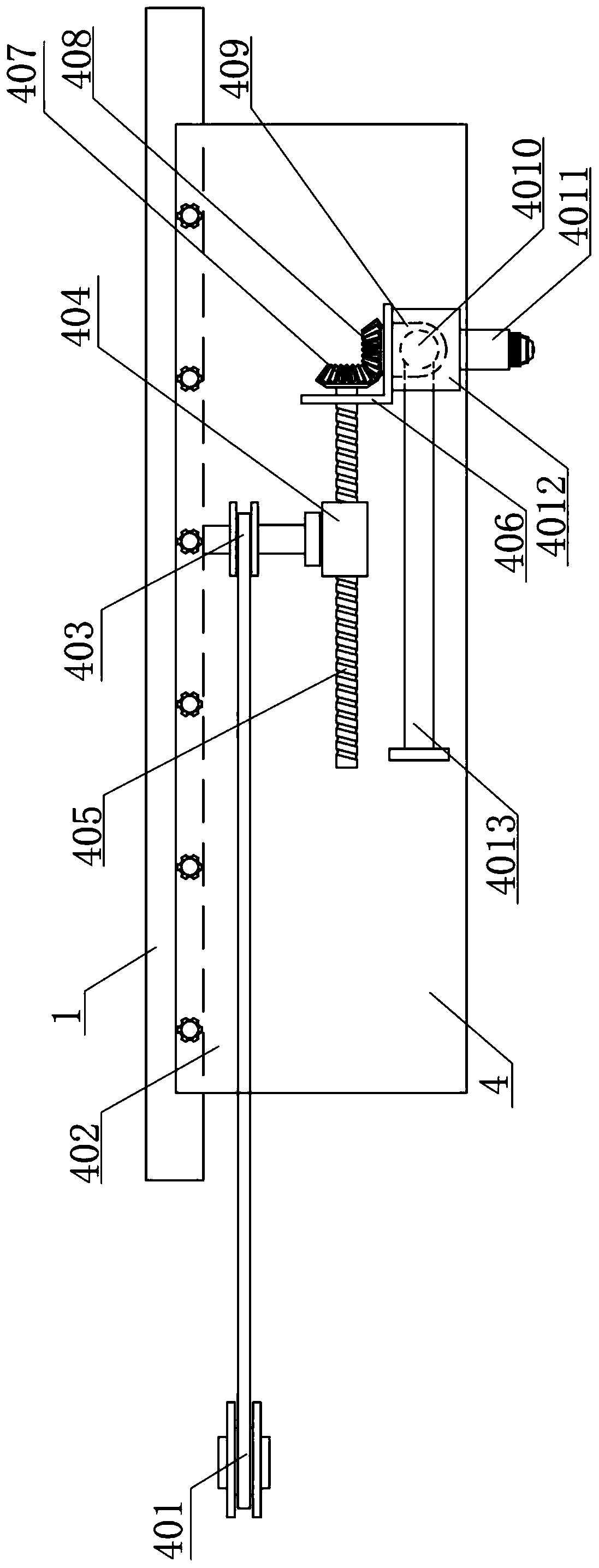

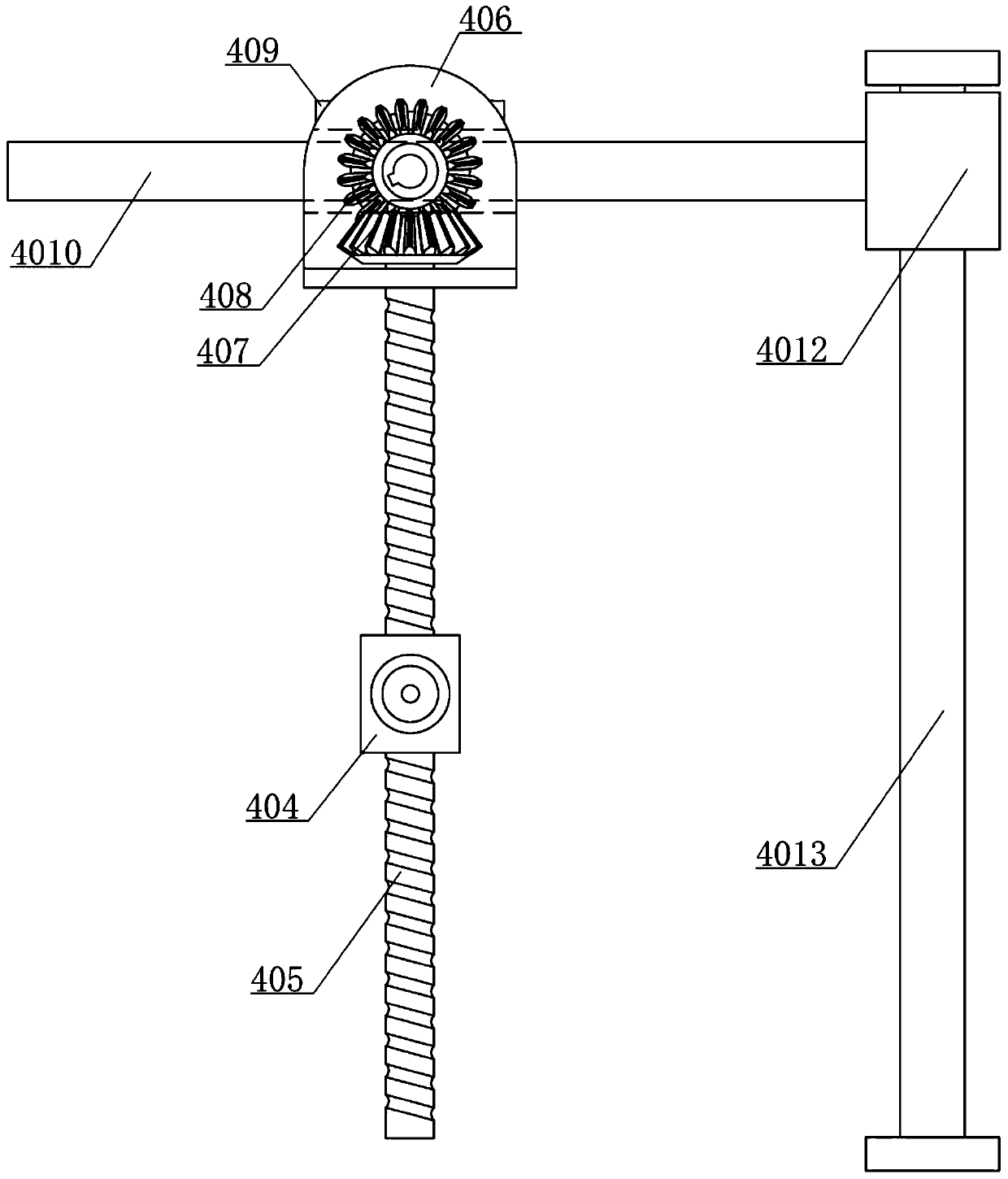

[0029] A double-sided sandblasting device for acid etching of art glass, such as Figure 1-7 As shown, it includes a support base 1, a control display 2, a gantry hanger 3, a screw-in sandblasting mechanism 4, a transfer stabilization mechanism 5, a turning mechanism 6, a stepping motor 7 and a first transmission wheel 8; the top left of the support base 1 The side is welded with the control display 2; the left part of the top of the support chassis 1 is welded with the gantry hanger 3, and the gantry hanger 3 is located on the right side of the control display 2; the left middle part of the top of the support chassis 1 is welded with the transfer stabilization mechanism 5, and The right part of the top of the transfer stabilization mechanism 5 is connected with the gantry hanger 3; the top right part of the support chassis 1 is provided with a turning mechanism 6; the middle part of the top of the support chassis 1 is connected with the stepper motor 7 by bolts; A screw-in sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com