Float glass transition roller cleaning method and transition roller for realizing float glass transition roller cleaning method

A float glass and transition roller technology, applied in glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc., can solve the problems of poor wiping effect, good cleaning effect, low labor intensity, etc., and save cleaning time and labor intensity. Low effect for precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

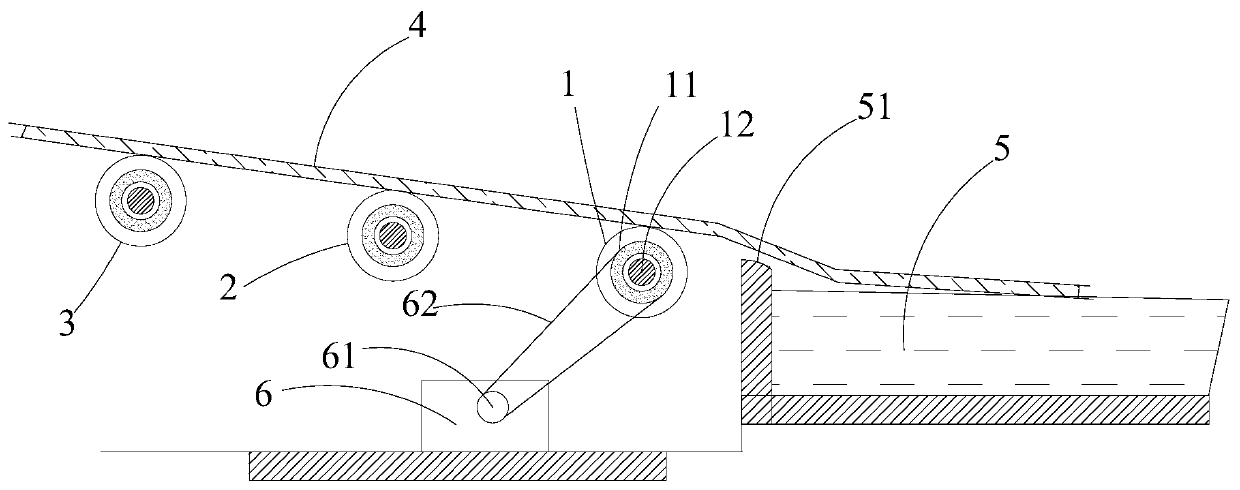

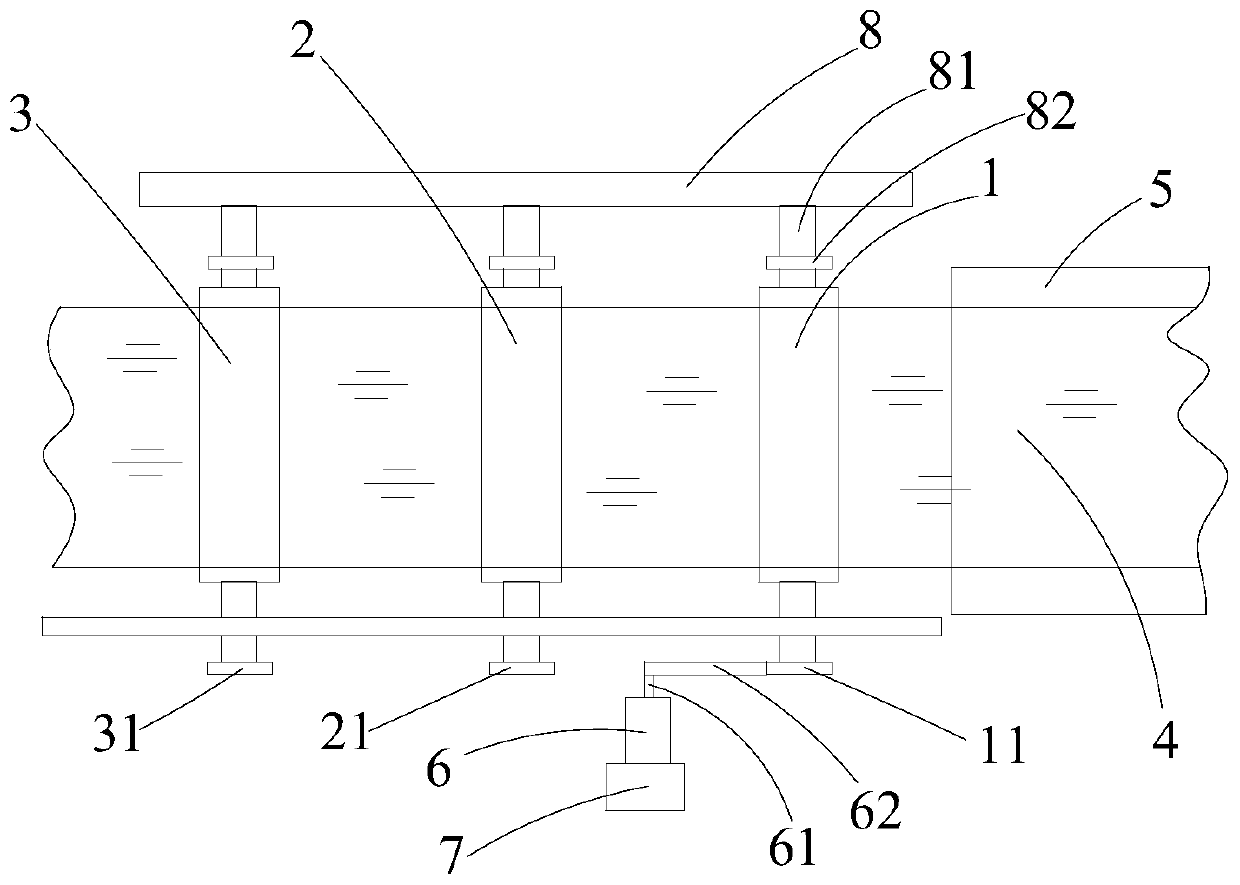

Image

Examples

Embodiment 1

[0067] This embodiment takes the production of SiCaNa white glass with a thickness of 4 mm as an example. The temperature at which the glass begins to soften is 552 ° C. The transition rolls include the first transition roll, the second transition roll, and the third transition roll that are successively away from the exit of the tin bath. The temperature at the tin notch is 610°C, the temperature at the first transition roll is 580°C, the temperature at the second transition roll position is 570°C, and the temperature at the third transition roll position is 560°C. The three transition rollers in this production line are respectively connected to the transmission device which drives independently. In order to realize the temperature rise of each transition roller, a heating device is provided for each transition roller in the transition roller slag box.

[0068] When cleaning the first transition roller, the steps are as follows:

[0069] S1 cleaning phase,

[0070] Increas...

Embodiment 2

[0075] This embodiment takes the production of SiCaNa white glass with a thickness of 4mm as an example. The temperature at which the glass begins to soften is 560°C. The transition rolls include the first transition roll, the second transition roll and the third transition roll which are successively away from the exit of the tin bath. The temperature at the tin notch is 610°C, the temperature at the first transition roll is 580°C, the temperature at the second transition roll position is 570°C, and the temperature at the third transition roll position is 560°C. The three transition rollers in this production line are respectively connected to the transmission device which drives independently. In order to realize the temperature rise of each transition roller, a heating device is provided for each transition roller in the transition roller slag box.

[0076] When cleaning the first transition roller, the steps are as follows:

[0077] S0 temperature adjustment stage,

[00...

Embodiment 3

[0085] The difference between this embodiment and Embodiment 2 is that the control parameters for the temperature of the first transition roll and the glass ribbon are slightly different, the ratio of the speed increase of the first transition roll and the running time are slightly different.

[0086] In this embodiment, in the S0 temperature adjustment stage, the temperature of the first transition roll is raised to 605°C, and the temperature of the glass ribbon at the tin notch is raised from 610°C to 615°C. Raise the height of the first transition roller by 3mm. In the S1 cleaning stage, increase the speed of the first transition roller by 5%. The cleaning time is 8 minutes.

[0087] In this embodiment, the degree of softening of the glass ribbon is higher than that in Embodiment 1. The speed should not be too fast to avoid breaking the board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com