Aerated brick preparation method

A technology of aerated bricks and raw materials, which is applied in the field of building materials and can solve the problems of easy mold of aerated bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

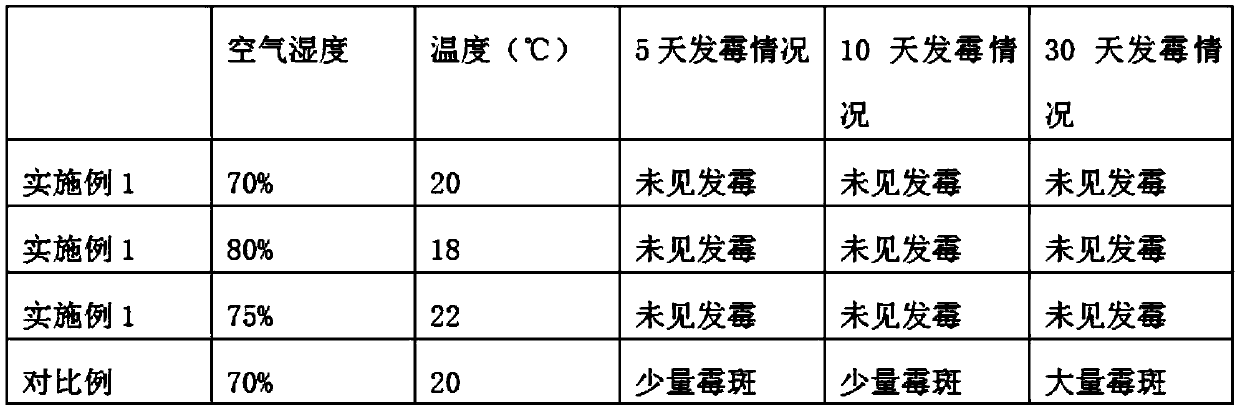

Image

Examples

Embodiment 1

[0018] A preparation method of firewood aerated brick, comprising the following steps:

[0019] Step 1. Grinding: The raw materials include the following components in parts by weight: 35 parts of fly ash, 10 parts of quicklime, 10 parts of diatomaceous earth, 5 parts of cement, 0.05 parts of aluminum powder, and 3 parts of gypsum. Put the above raw materials into the grinding Grinding in the machine, adding to the mixer after grinding, then adding water to the mixer and fully stirring to obtain the mixture;

[0020] Step 2, adding additives: Add 1 part of dry ice particles, 0.3 parts of sodium chloride and 0.5 parts of fluorosurfactant into the mixer and stir, the diameter of the dry ice particles is 1 cm;

[0021] Step 3. Heating: Pour the mixture into the mold for extrusion molding, and then move it into the drying room for drying. The temperature of the drying room is kept at 42°C, and the drying time is 1 hour to obtain rough bricks;

[0022] Step 4, steam curing: Put th...

Embodiment 2

[0024] A preparation method of firewood aerated brick, comprising the following steps:

[0025] Step 1. Grinding: The raw materials include the following components in parts by weight: 37 parts of fly ash, 13 parts of quicklime, 13 parts of diatomaceous earth, 7 parts of cement, 0.055 parts of aluminum powder, and 6 parts of gypsum. Put the above raw materials into the grinding Grinding in the machine, adding to the mixer after grinding, then adding water to the mixer and fully stirring to obtain the mixture;

[0026] Step 2, adding additives: add 1.5 parts of dry ice particles, 0.35 parts of sodium chloride and 0.6 parts of fluorosurfactant into the mixer and stir, the diameter of the dry ice particles is 1.2 cm;

[0027] Step 3. Heating: Pour the mixture into the mold for extrusion molding, then move it into the drying room for drying. The temperature of the drying room is kept at 42 ° C, and the drying time is 2 hours to obtain rough bricks;

[0028] Step 4, steam curing: ...

Embodiment 3

[0030] A preparation method of firewood aerated brick, comprising the following steps:

[0031] Step 1. Grinding: The raw materials include the following components in parts by weight: 40 parts of fly ash, 15 parts of quicklime, 15 parts of diatomaceous earth, 8 parts of cement, 0.06 parts of aluminum powder, and 8 parts of gypsum. Put the above raw materials into the grinding Grinding in the machine, adding to the mixer after grinding, then adding water to the mixer and fully stirring to obtain the mixture;

[0032] Step 2, adding additives: add 2 parts of dry ice particles, 0.4 parts of sodium chloride and 0.7 parts of fluorosurfactant into the mixer and stir, the diameter of the dry ice particles is 1.5cm;

[0033] Step 3. Heating: the mixture is poured into the mold for extrusion molding, and then moved into the drying room for drying. The temperature of the drying room is kept at 42°C, and the drying time is 3 hours to obtain rough bricks;

[0034] Step 4, steam curing: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com