Manufacturing method of wave-absorbing material and wave-absorbing material adhesive tape structure

A technology of a wave absorbing material and a manufacturing method, which is applied in the field of wave absorbing materials to achieve the effects of high viscosity, smooth and flat surface, and meeting rigid requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

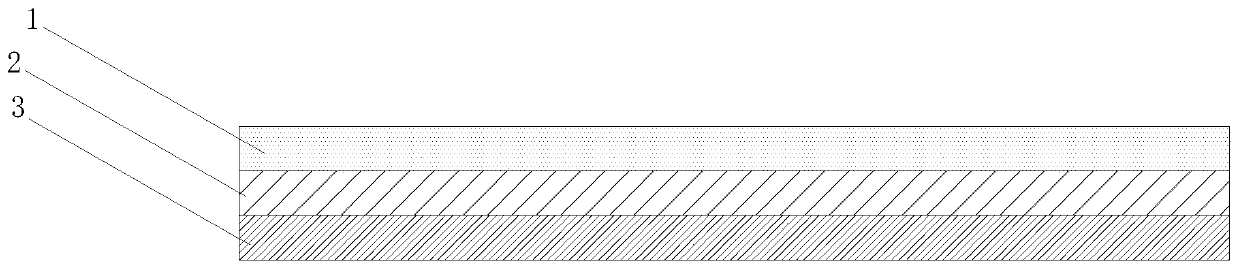

Image

Examples

Embodiment 1

[0030] Coating front stage: Use a glue melter to stir EPDM rubber and cyclohexanone at a ratio of 1:2 at a temperature of 70°C and a stirring speed of 100r / min until the colloid is fully dissolved;

[0031] After dissolving, let it stand at room temperature for 24 hours, then add BYK wetting and dispersing agent to EPDM rubber in a ratio of 0.8:1, flake sendust magnetic powder and EPDM rubber in a ratio of 6:1, and then add Cyclohexanone, add cyclohexanone until the total amount of cyclohexanone added is 1 time of the total weight of EPDM rubber and sheet sendust magnetic powder, stir at room temperature for 1 hour, the stirring speed is 100r / min, stir After the completion, it can be coated on the machine;

[0032] Coating and vulcanization process: The release film with a thickness of 0.05um is used as the base material, and the coating process is adopted. The temperature of each section of the oven is set at 85°C, and the speed is 0.5M / min. A uniform layer is formed on the r...

Embodiment 2

[0034] Coating front stage: Use a melter to mix polyurethane and methyl ethyl ketone at a ratio of 1:3 at a temperature of 80°C and a stirring speed of 90r / min until the colloid is fully dissolved;

[0035] After dissolving, let stand at room temperature for 30 hours, then add BYK Wetting and Dispersing Agent to polyurethane at a ratio of 0.9:1, flake sendust magnetic powder and polyurethane at a ratio of 10:1, then add methyl ethyl ketone, and add methyl ethyl ketone to The total amount of methyl ethyl ketone added is 1.2 times the total weight of polyurethane and flaky sendust magnetic powder. Stir at room temperature for 1 hour at a stirring speed of 300r / min. After the stirring is completed, it can be coated on the machine;

[0036] Coating and vulcanization process: The release film with a thickness of 0.05um is used as the base material, and the coating process is adopted. The temperature of each section of the oven is set at 120°C, and the speed is 1.5M / min. A uniform la...

Embodiment 3

[0038] Coating front stage: Use a melter to mix polyurethane and xylene at a ratio of 1:5, at a temperature of 90°C, and at a stirring speed of 95r / min until the colloid is fully dissolved;

[0039] After dissolving, let stand at room temperature for 48 hours, then add BYK Wetting and Dispersing Agent to polyurethane at a ratio of 0.9:1, flake sendust magnetic powder and polyurethane at a ratio of 8:1, then add xylene, and add xylene to The total amount of xylene added is 1.2 times the total weight of polyurethane and flaky sendust magnetic powder. Stir at room temperature for 1 hour at a stirring speed of 500r / min. After the stirring is completed, it can be coated on the machine;

[0040] Coating and vulcanization process: use the release film with a thickness of 0.05um as the base material, adopt the coating process, set the temperature of each section of the oven at 135°C, and the speed of 1.3M / min to form a uniform layer on the release surface of the release layer However,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com