Large and medium-sized machine tool special-shaped plate piece stamping equipment for machining

A technology of mechanical processing and stamping equipment, applied in metal processing equipment, safety equipment, forming tools, etc., can solve the problems of workpiece damage, inability to allow efficient extension of plates, and inability to make workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

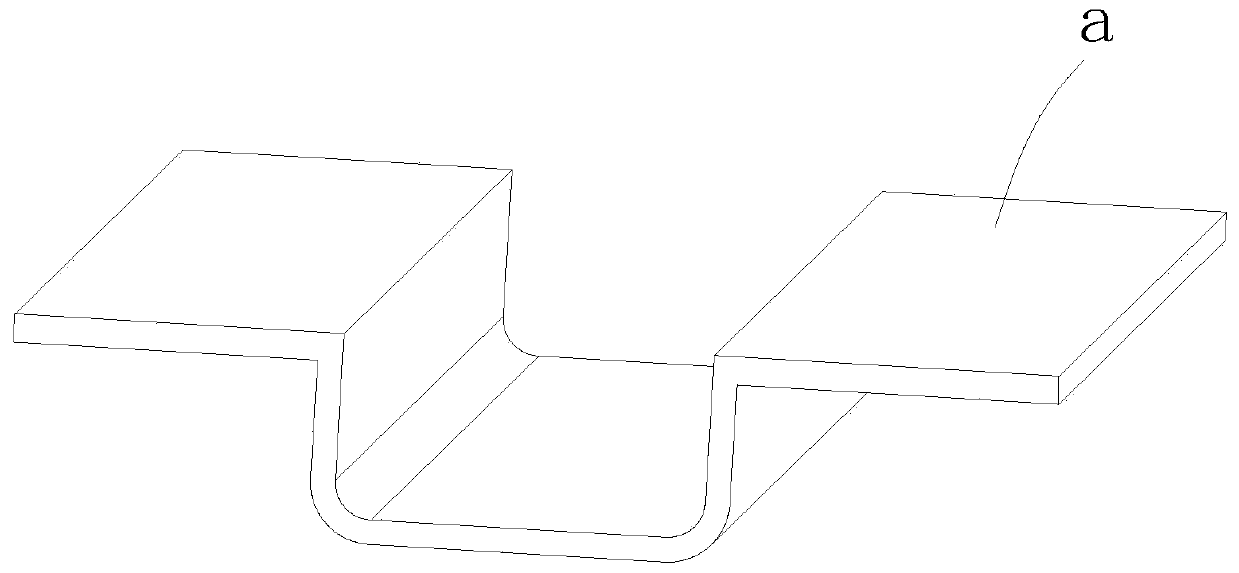

[0047] A stamping equipment for large and medium-sized machine tool special-shaped plate parts for mechanical processing, such as image 3 As shown, the special-shaped plate a has a bottom wall with a shallow U-shaped structure and side portions formed by extending vertically outward from both sides of the upper end of the shallow U-shaped bottom wall;

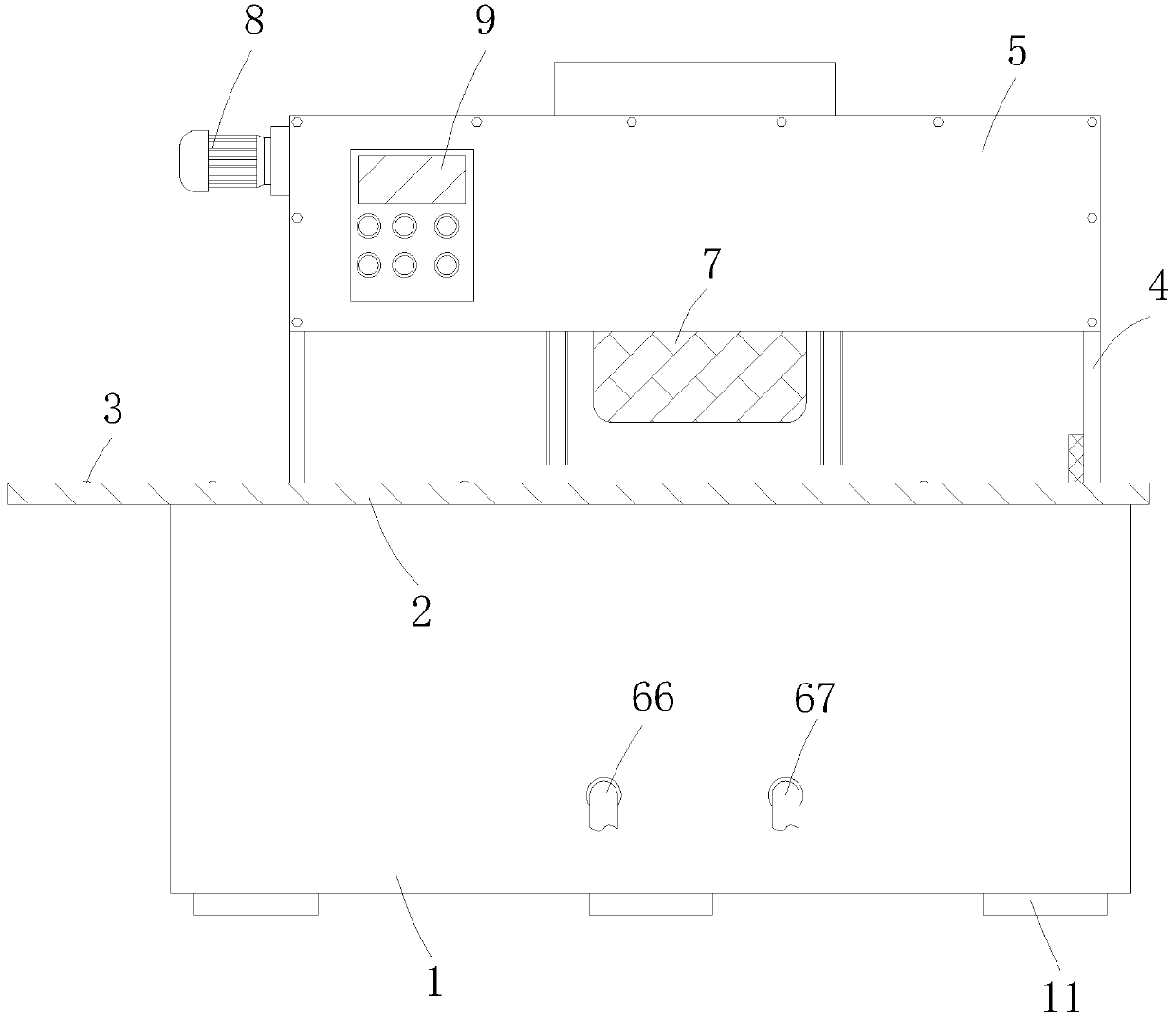

[0048] The stamping equipment comprises a base box 1, a plurality of supporting feet 11 installed at the lower end of the base box 1, and a processing platform 2 installed at the upper end of the base box 1. The upper end of the processing platform 2 is provided with a processing chamber 4 with a front opening, and The upper end of the front wall is equipped with a front sealing plate 5 through screws, which plays a good protective role. The inner cavity of the processing chamber 4 is provided with an upper mold assembly 7, and the lower part of the upper mold assembly 7 is equipped with a stamping plate for special-shaped plat...

Embodiment 2

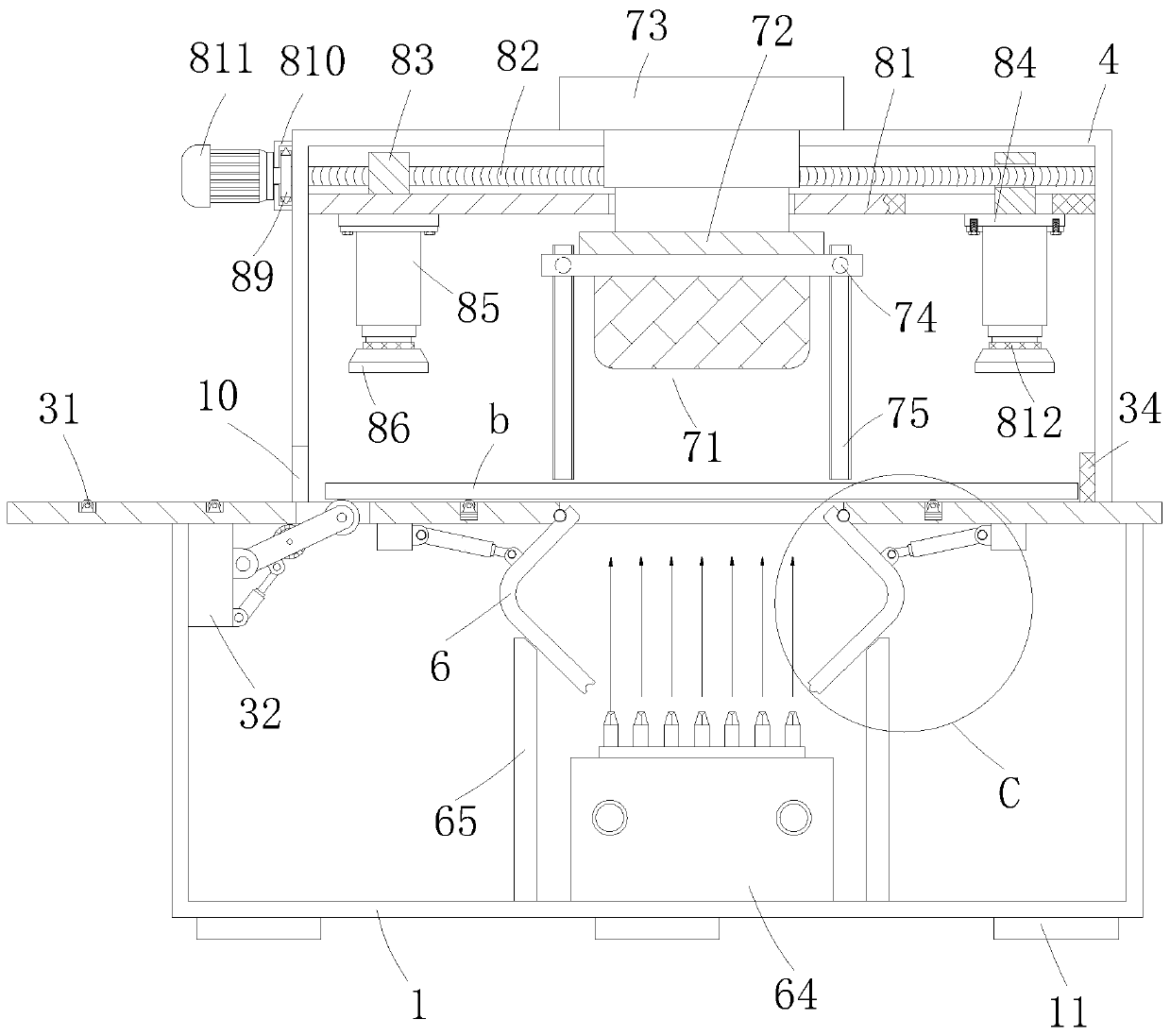

[0062] The difference between this embodiment and embodiment 1 is that, as figure 2 As shown, the upper end surface of the processing platform 2 is provided with a transmission mechanism 3 for feeding the sheet material b to be processed. The transmission mechanism 3 includes a plurality of Rotate the set transmission wheel 31;

[0063]The elastic member 33 arranged at the lower end of the transmission wheel 31 can be understood that the elastic member 33 can be a polyurethane elastic layer. After pre-adjustment, when the plate b to be processed is placed on the transmission wheel 31, the transmission wheel 31 shrinks downward Finally, the rotation transmission of the transmission wheel 31 can be realized; at the same time, after the electric push rod III 85 extends downward to press the plate b to be processed, the transmission wheel 31 can continue to shrink downwards, ensuring that the plate b to be processed is placed flatly on the processing The upper end of platform 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap