Transfer, posture adjustment and docking device for cabin

A technology for docking devices and cabins, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of low assembly efficiency, uncontrollable quality, poor stability, etc., and achieve the effect of eliminating relative movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

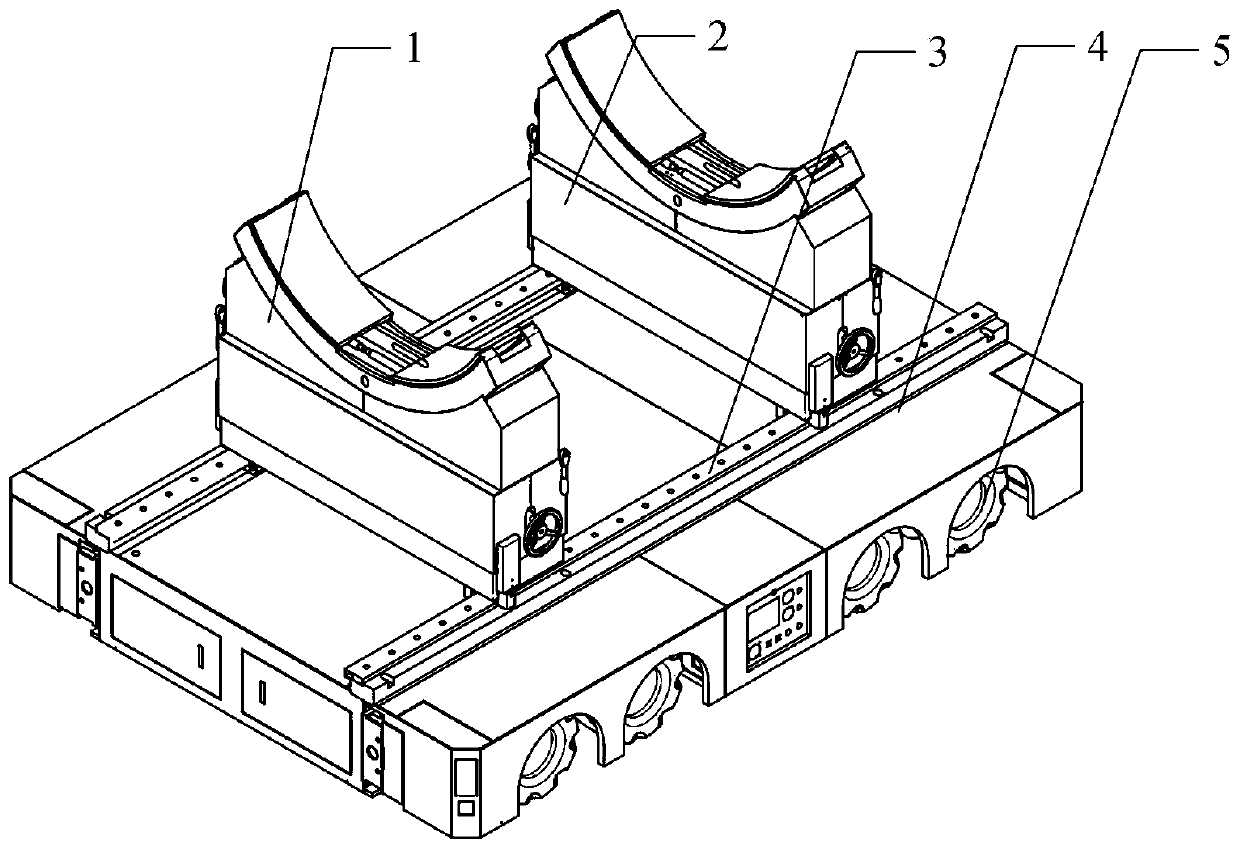

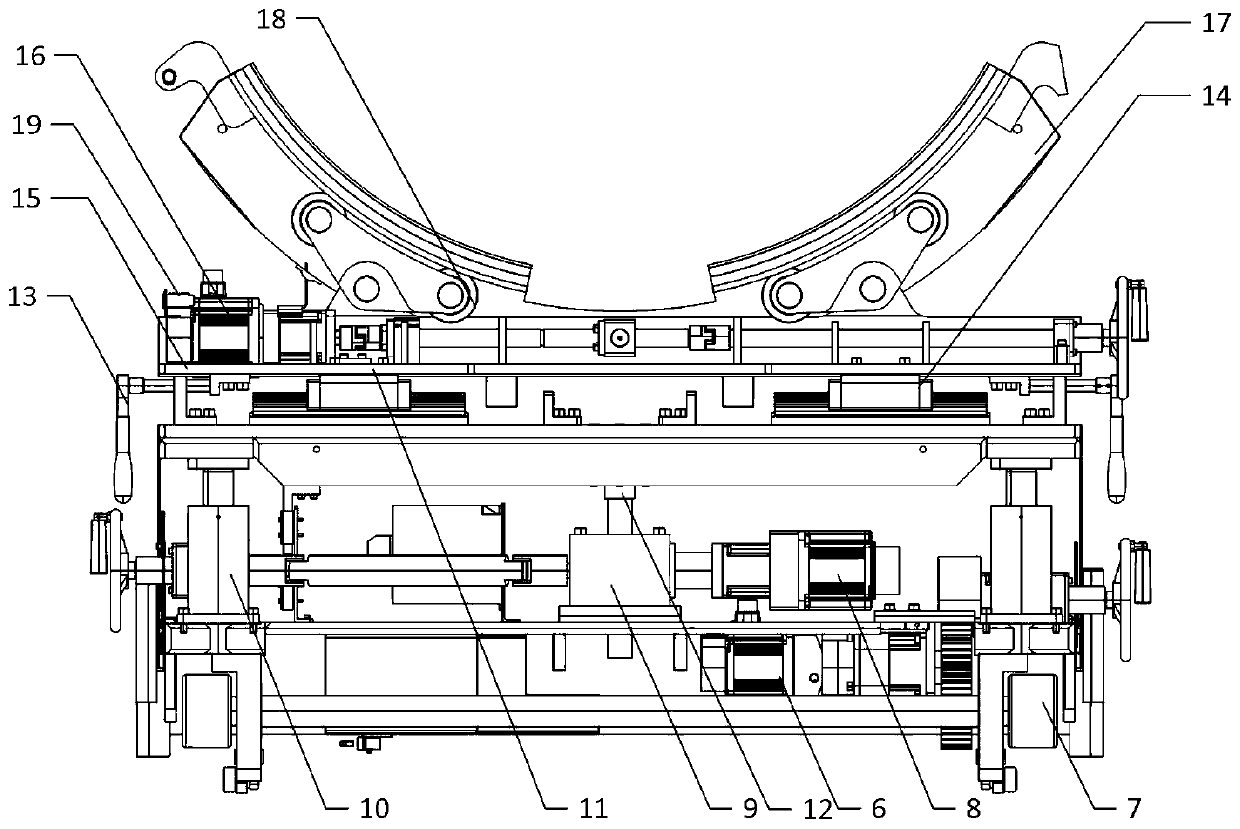

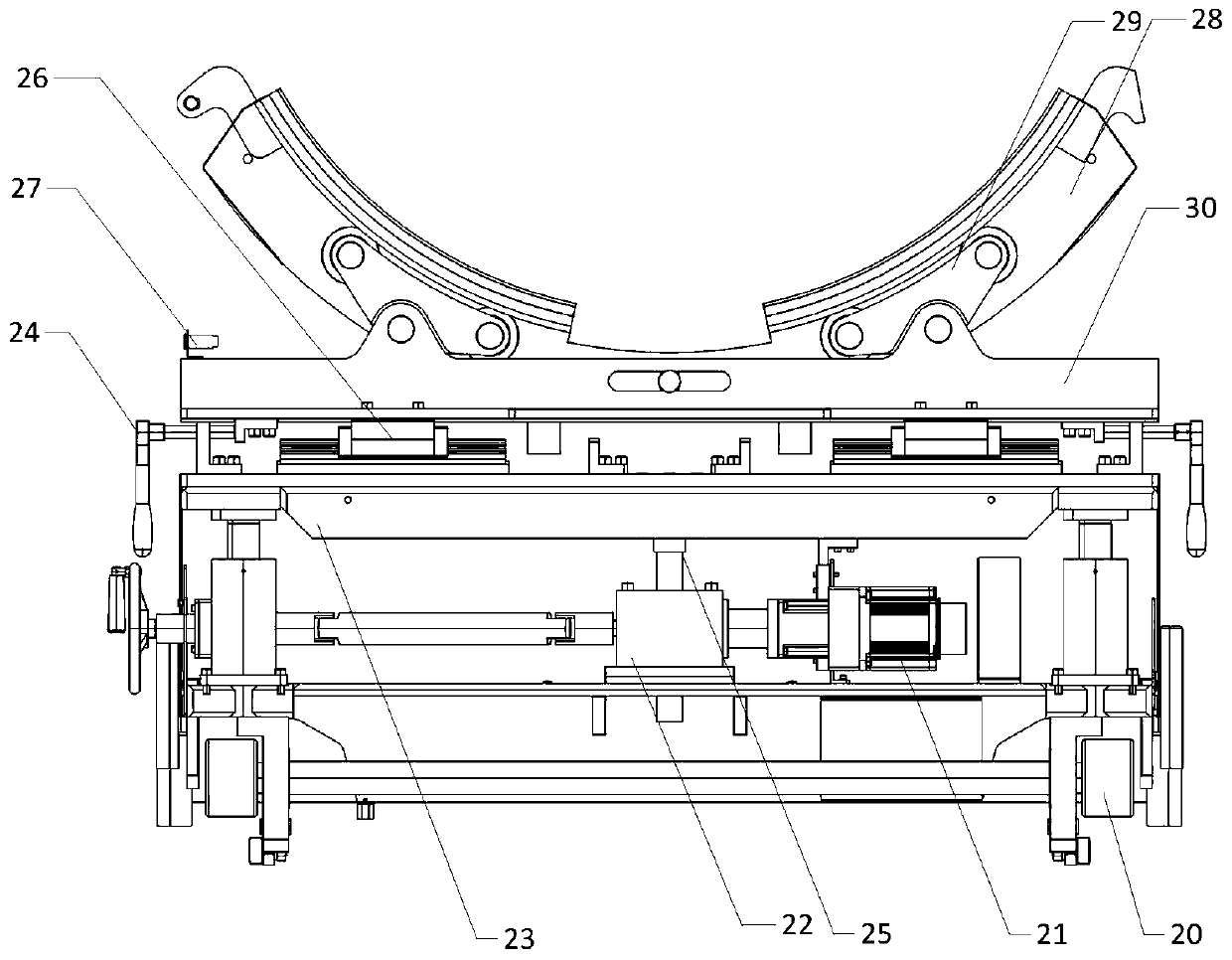

[0021] The invention proposes a device for transfer, attitude adjustment and docking of arc cabin sections. The front supporting trolley and the rear supporting trolley of the device are placed on the guide rail based on the mecanum wheel transfer vehicle, and both trolleys have the functions of walking, lifting, rolling and lateral movement. The movement and rollover of the rear support trolley take the initiative, and the front support trolley moves accordingly, moving and rolling in synchronization with the movement of the rear support trolley. The device can realize the high-precision attitude adjustment of the carrying arc cabin in six degrees of freedom, and also has the omnidirectional transfer function of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com