BOPBT thin film and preparation method thereof

A film and surface layer technology, applied in the field of BOPBT film and its preparation, to achieve excellent weather resistance, cost reduction, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

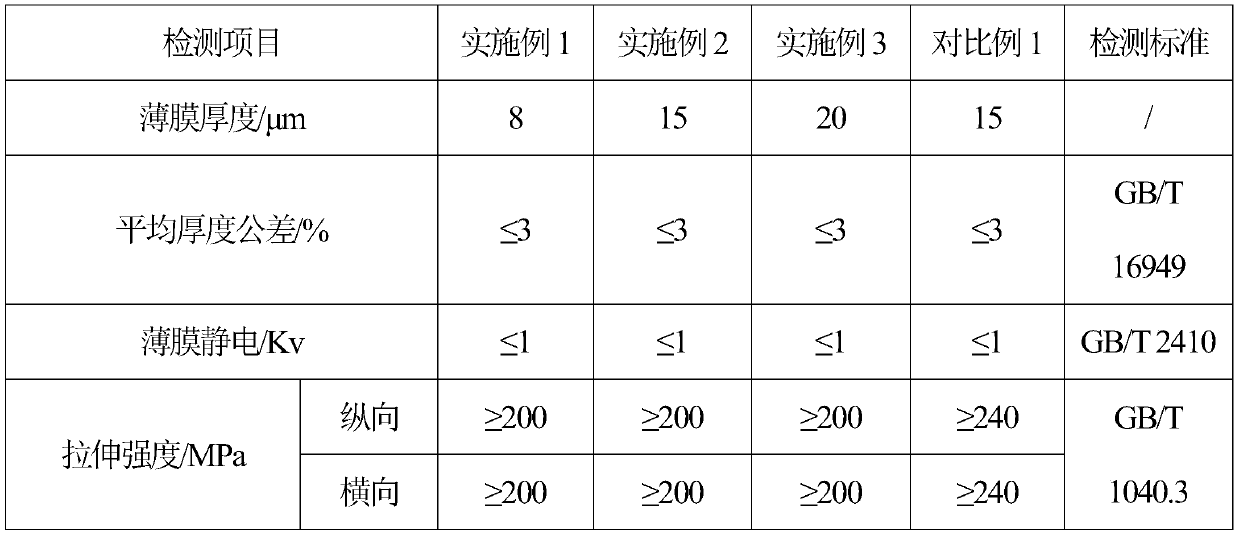

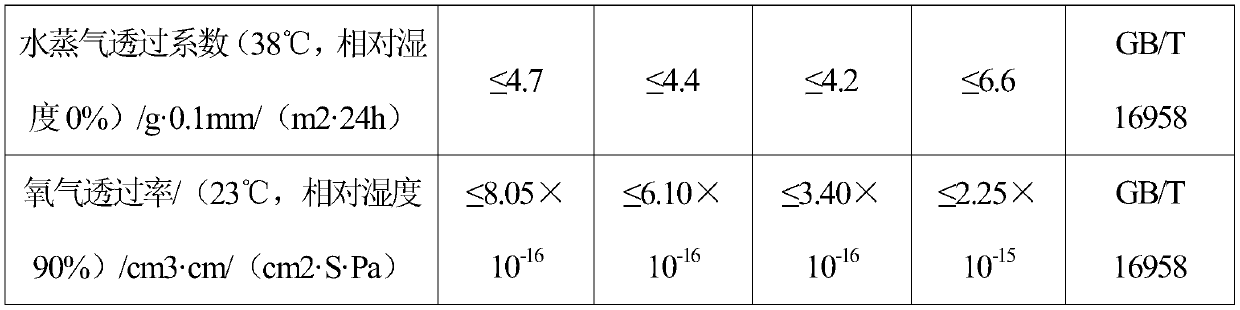

Examples

Embodiment 1

[0021] A kind of BOPBT film, is made of upper surface layer, core layer, lower surface layer successively; Described core layer is PBT polyester chip, and the raw material of upper surface layer and lower surface layer is all by weight percentage by 70% PBT polyester chip and 30% Composed of PBT polyester masterbatch; the thickness of the upper surface layer accounts for 10% of the total thickness of the BOPBT film, the thickness of the lower surface layer accounts for 10% of the total thickness of the BOPBT film, and the thickness of the core layer accounts for 80% of the total thickness of the BOPBT film.

[0022] The preparation method of above-mentioned BOPBT film, comprises the steps:

[0023] S1. Take the PBT polyester chips and dry them at 110-120°C for 2-3 hours, heat and melt them in a single-screw extruder, and filter to obtain the core layer melt; Vacuum, remove water and impurities to obtain the upper surface melt; remove the surface material and heat and melt it i...

Embodiment 2

[0027] A kind of BOPBT film, is made of upper surface layer, core layer, lower surface layer successively; Described core layer is PBT polyester chip, and the raw material of upper surface layer and lower surface layer is all by weight percentage by the PBT polyester chip of 73% and 27% Composed of PBT polyester masterbatch; the thickness of the upper surface layer accounts for 11% of the total thickness of the BOPBT film, the thickness of the lower surface layer accounts for 11% of the total thickness of the BOPBT film, and the thickness of the core layer accounts for 78% of the total thickness of the BOPBT film.

[0028] The preparation method of above-mentioned BOPBT film, comprises the steps:

[0029] S1. Take the PBT polyester chips and dry them at 110-120°C for 2-3 hours, heat and melt them in a single-screw extruder, and filter to obtain the core layer melt; Vacuum, remove water and impurities to obtain the upper surface melt; remove the surface material and heat and me...

Embodiment 3

[0033] A kind of BOPBT film, is made of upper surface layer, core layer, lower surface layer successively; Described core layer is the PBT polyester chip, and the raw material of upper surface layer and lower surface layer is by weight percentage all by the PBT polyester chip of 76% and 24% Composed of PBT polyester masterbatch; the thickness of the upper surface layer accounts for 12% of the total thickness of the BOPBT film, the thickness of the lower surface layer accounts for 12% of the total thickness of the BOPBT film, and the thickness of the core layer accounts for 76% of the total thickness of the BOPBT film.

[0034] The preparation method of above-mentioned BOPBT film, comprises the steps:

[0035] S1. Take the PBT polyester chips and dry them at 110-120°C for 2-3 hours, heat and melt them in a single-screw extruder, and filter to obtain the core layer melt; Vacuum, remove water and impurities to obtain the upper surface melt; remove the surface material and heat an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com