A wear-resistant glaze for preparing sanitary ceramics and a method for preparing sanitary ceramics

A technology of sanitary ceramics and glazes, applied in the field of sanitary ceramics, can solve the problems of glazed surface gloss reduction, color fading, dirt infiltration, etc., and achieve the effect of reducing glaze wear, smooth and delicate surface, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

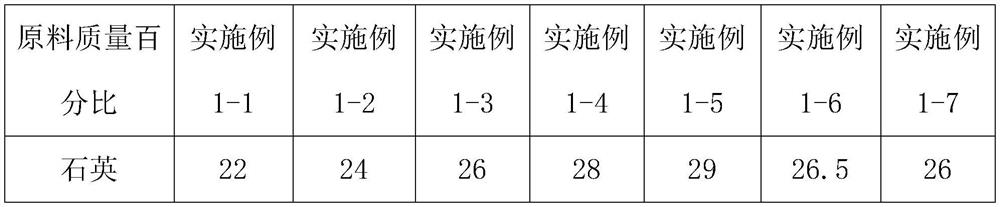

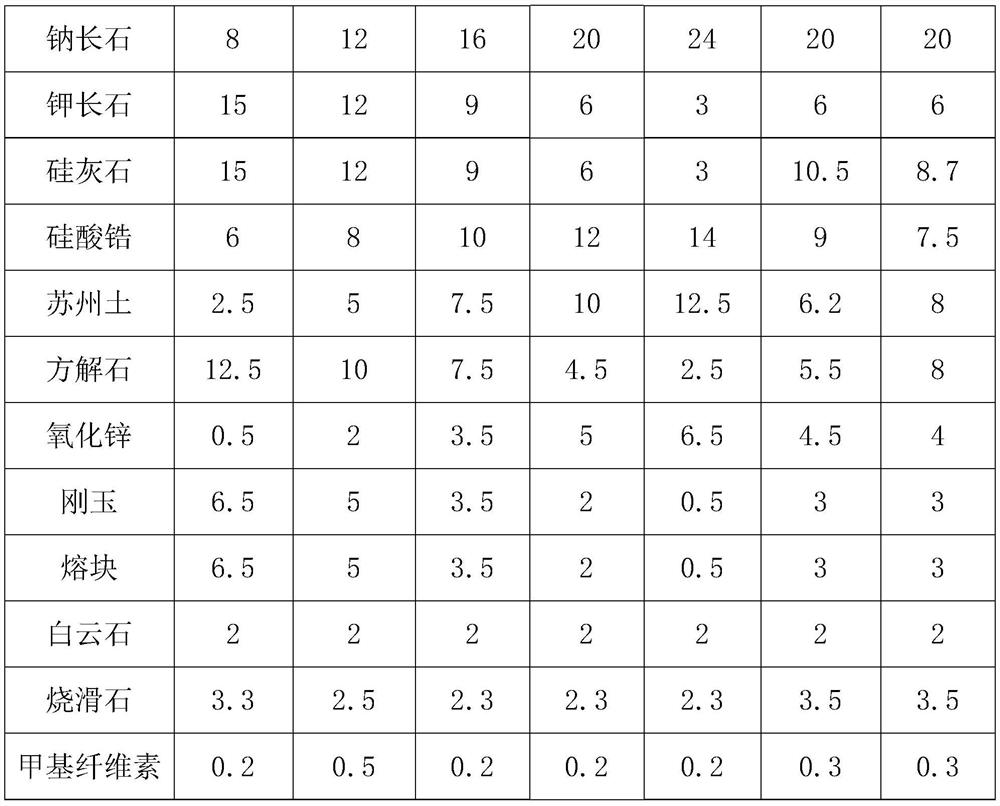

[0024] A wear-resistant glaze for preparing sanitary ceramics, comprising the following components according to mass percentage: 24-28% of quartz, 20-32% of feldspar, 6-13% of wollastonite, 8-12% of zirconium silicate, Suzhou soil 5-10%, calcite 5-10%, zinc oxide 2-5%, corundum 2-5%, frit 2-5%, dolomite 2-5%, calcined talc 2-5% and methyl cellulose Su 0.2 ~ 0.5%.

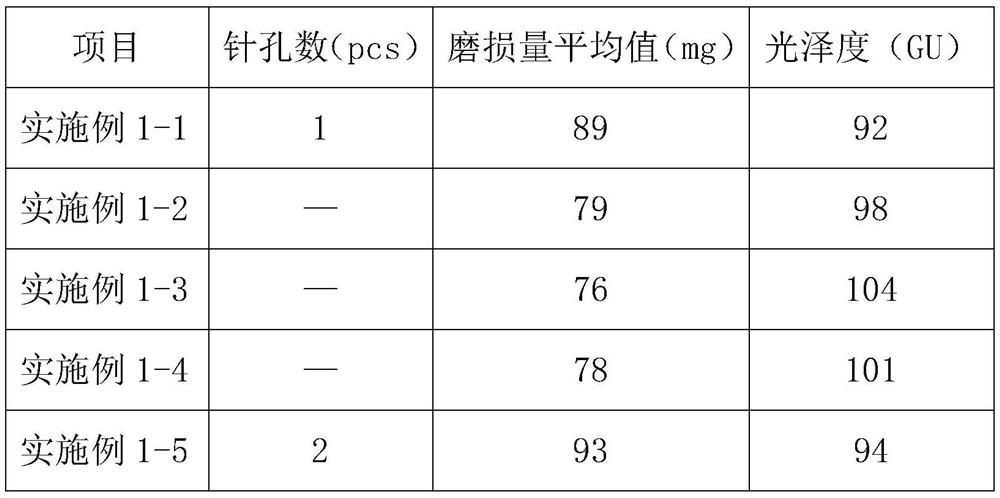

[0025] The existing glazed surface of sanitary ceramics is measured according to the test method of GB / T3810.7-2016 ceramic tiles for the surface wear resistance of glazed tiles. Glazed surfaces in the wear value range are still prone to wear marks and dirt during daily use, which is far from meeting the wear and gloss requirements of sanitary ceramic glazed surfaces. In the existing tiles, the main reason for the low wear value of the glaze is that the Al / Si ratio of the formula components is low. At the same time, because no high wear-resistant raw materials are used or the proportion of wear-resistant raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com