Automatic high-precision non-ironing pocket setting machine

A non-iron bag machine, high-precision technology, applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of high labor cost, insufficient positioning accuracy, low production efficiency, etc., to reduce labor intensity, The effect of improving sewing quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

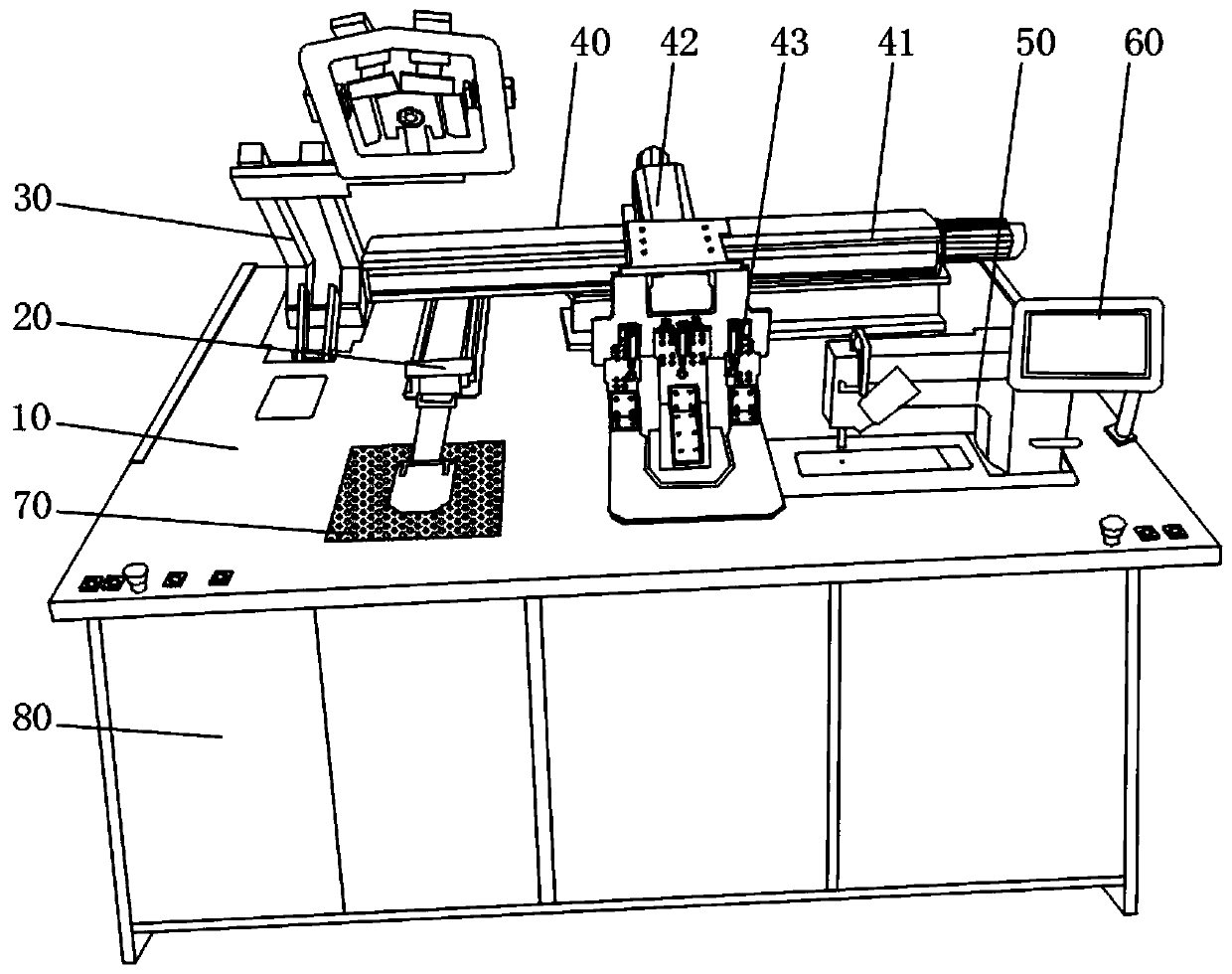

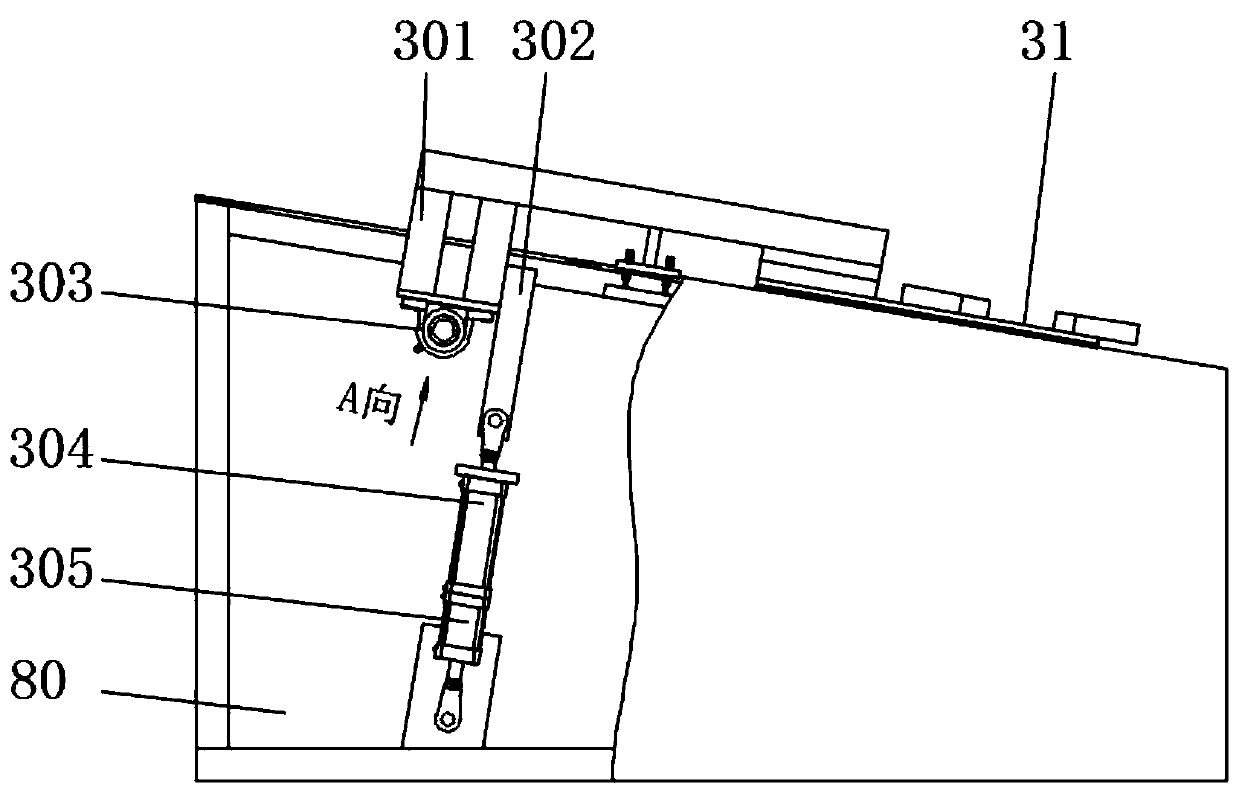

[0055] Embodiment one, with reference to figure 1 , image 3 , Figure 4 , Figure 5 with Image 6 , a high-precision automatic non-ironing bag sticking machine, including a work surface 10, a bag piece auxiliary mechanism 20, a turning mechanism 30, a feeding unit 40, a sewing machine head 50, a display screen 60, and a frame body 80, and the work surface 10 is welded on the frame body 80 top surface, and the inner side of the frame body 80 runs through the worktable 10 to install the bag piece auxiliary mechanism 20 and the turning mechanism 30, and the upper surface of the worktable 10 is equipped with a feeding unit 40 through welding parts, and the feeding unit 40 includes X-axis moving components 41. The Y-axis moving assembly 42 and the pressing assembly 43. One side of the pressing assembly 43 is located on the upper surface of the worktable 10 and is provided with a sewing machine head 50. The turning mechanism 30 includes a turning frame 301, a driving arm 302, a ...

Embodiment 2

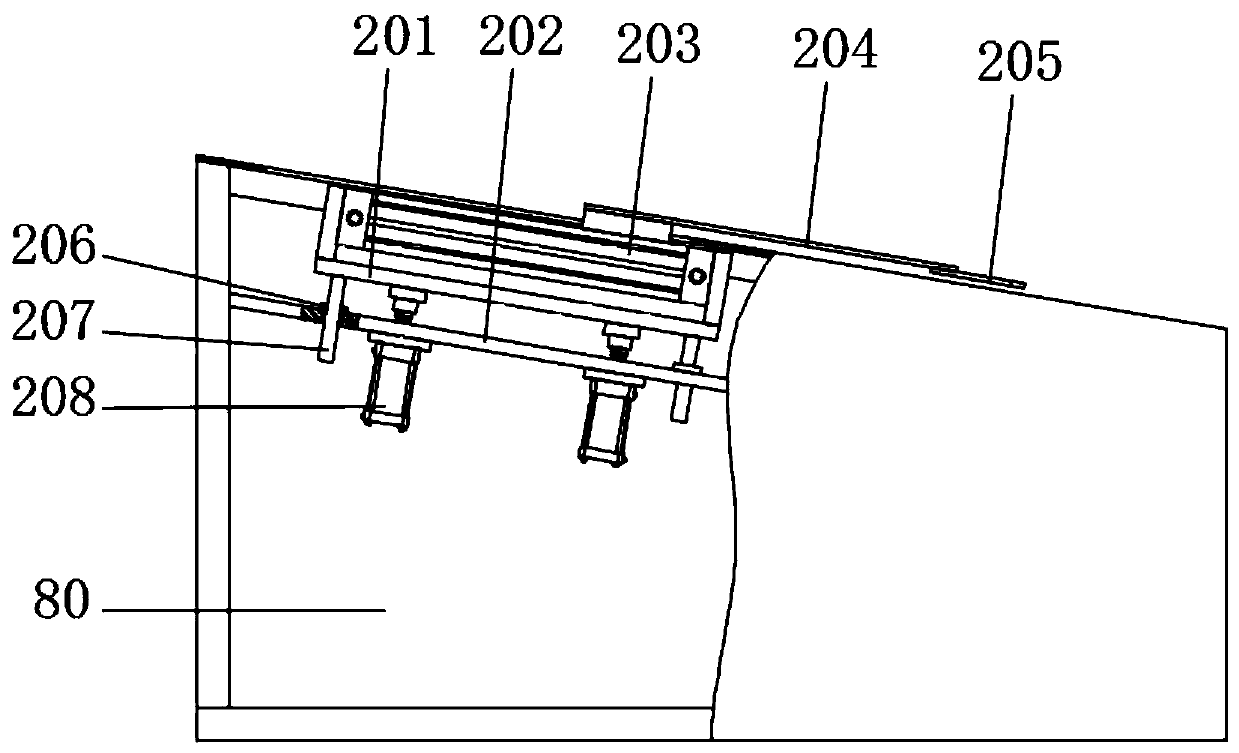

[0059] Embodiment two, refer to Figure 1-2 , the bag piece auxiliary mechanism 20 includes a cylinder mounting frame 201, a cylinder fixing plate 202, a rodless cylinder 203, a connecting arm 204, a bag piece fixing plate 205, a guide flange 206, a guide rod 207, a jacking cylinder 208, and a cylinder fixing plate 202 It is welded inside the frame body 80, and two jacking cylinders 208 are installed on the bottom of the cylinder fixing plate 202, and the driving rod of each jacking cylinder 208 is connected with the cylinder mounting frame 201, and a guide flange is embedded on the surface of the cylinder mounting frame 201 206, and the guide rod 207 is slidingly connected with the guide flange 206, the top of the guide rod 207 is connected with the cylinder mounting frame 201, and the rodless cylinder 203 is installed inside the cylinder mounting frame 201, and the top of the rodless cylinder 203 is connected with one end of the connecting arm 204, And the connecting arm 204...

Embodiment 3

[0061] Embodiment three, refer to Figure 7-10 , X-axis moving assembly 41 includes X-axis servo motor 41.1, X-axis coupling 41.2, X-axis screw nut 41.3, X-axis moving seat 41.4, X-axis screw 41.5, X-axis fixed bearing seat 41.6, X-axis guide rail assembly 41.7 , X-axis protective shell 41.8, connecting plate 41.9, X-axis protective shell 41.8 section is "U"-shaped structure, and one end of X-axis protective shell 41.8 is installed with X-axis servo motor 41.1, and the output shaft of X-axis servo motor 41.1 extends to X-axis The inside of the protective shell 41.8 is connected to the X-axis screw 41.5 through the X-axis coupling 41.2, and the two ends of the X-axis screw 41.5 are erected inside the X-axis protective shell 41.8 through the X-axis fixed bearing seat 41.6, and the two sides of the X-axis screw 41.5 An X-axis guide rail assembly 41.7 is provided, and an X-axis moving seat 41.4 is slidably connected to the X-axis guide rail assembly 41.7. One end of the X-axis mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com