A kind of fabric wrinkle removal device for textile

A cloth and cloth guide technology, which is applied in the direction of processing textile material equipment configuration, processing textile material carrier, spraying/spraying textile material processing, etc., can solve the problems of poor cloth leveling effect, troublesome installation and replacement, and reduced processing efficiency. Achieve the effects of improved processing efficiency, simple structure and good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

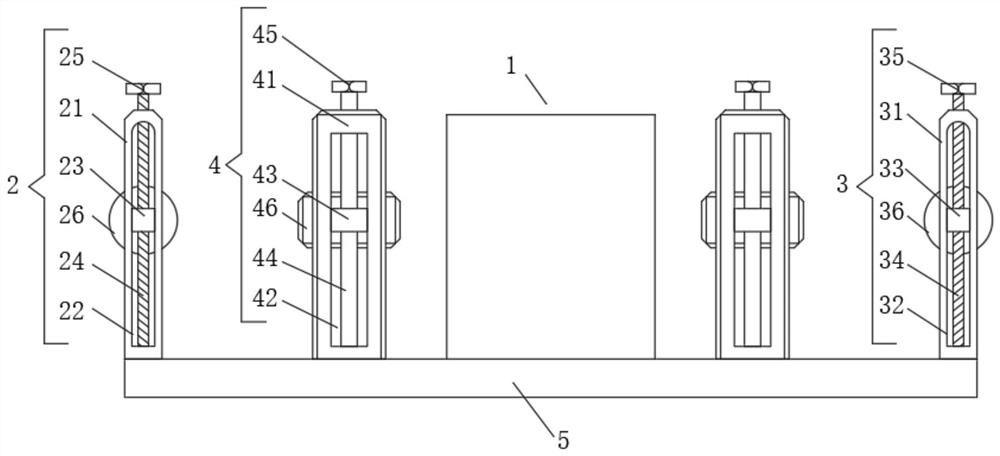

[0028] Example: such as Figure 1-10 As shown, the present invention is a kind of cloth wrinkle removal device for textile, comprising wrinkle removal assembly 1, cloth release assembly 2, cloth collection assembly 3, cloth guiding and leveling assembly 4 and base 5, said wrinkle removal assembly 1, cloth release assembly 2. Both the cloth receiving assembly 3 and the cloth guiding and leveling assembly 4 are arranged above the base 5, and the cloth releasing assembly 2 and the cloth receiving assembly 3 are respectively arranged on both sides of the wrinkle removing assembly 1, and the cloth guiding and leveling assembly 4 is provided with two, and the two cloth guiding and leveling assemblies 4 are respectively arranged on both sides of the wrinkle removing assembly 1, and the two said cloth guiding and leveling assemblies 4 are respectively located near the cloth releasing assembly 2 and the cloth receiving assembly 3 One side of wrinkle removal unit 1.

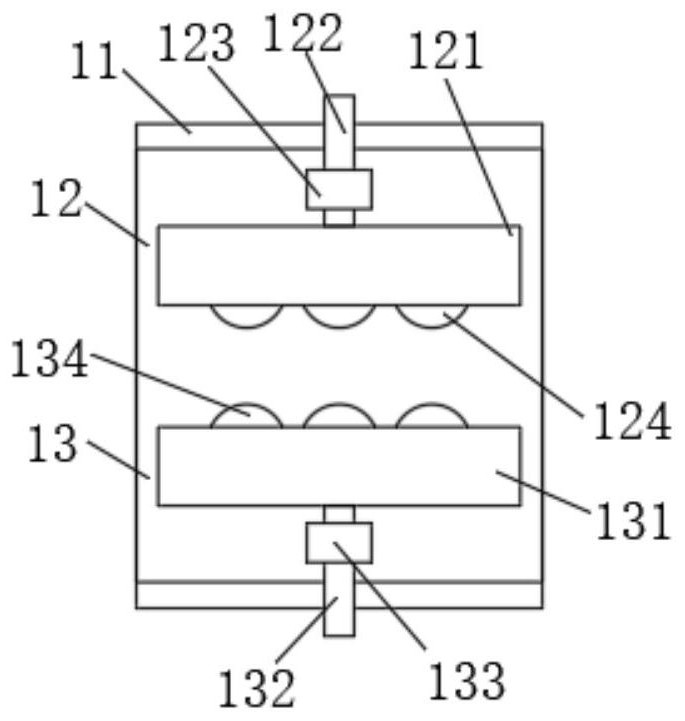

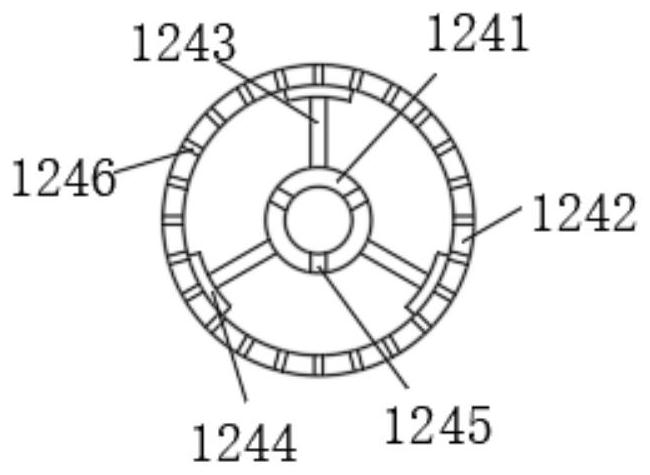

[0029] The wrinkl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com