Mobile robot damper

A mobile robot, shock absorber technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of complex structure, poor durability of compression springs, short service life, etc., to simplify the structure of mobile robots , the load capacity can be adjusted, and the effect of improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

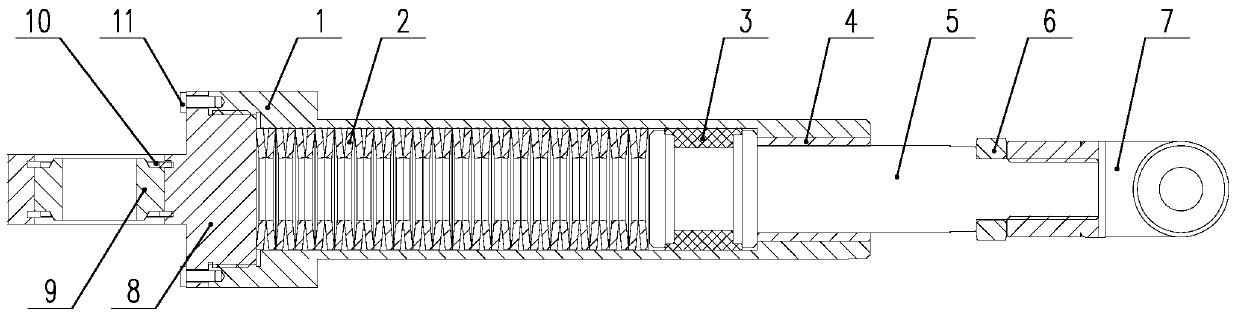

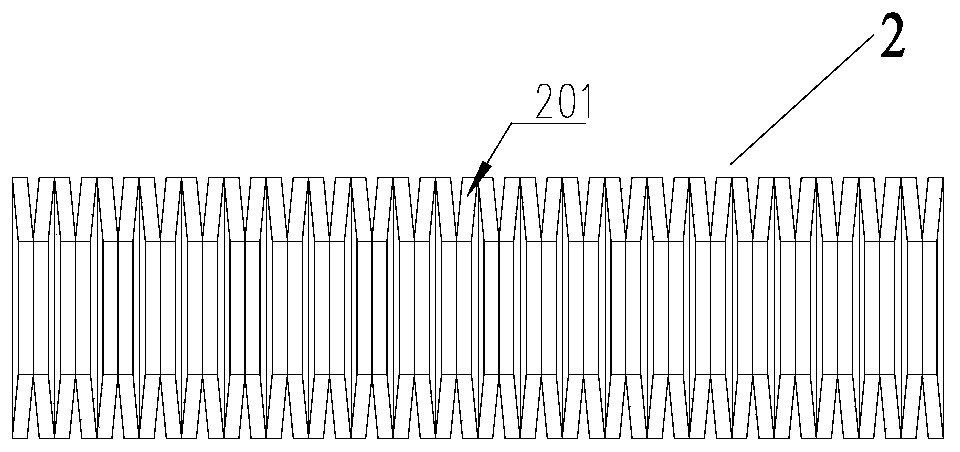

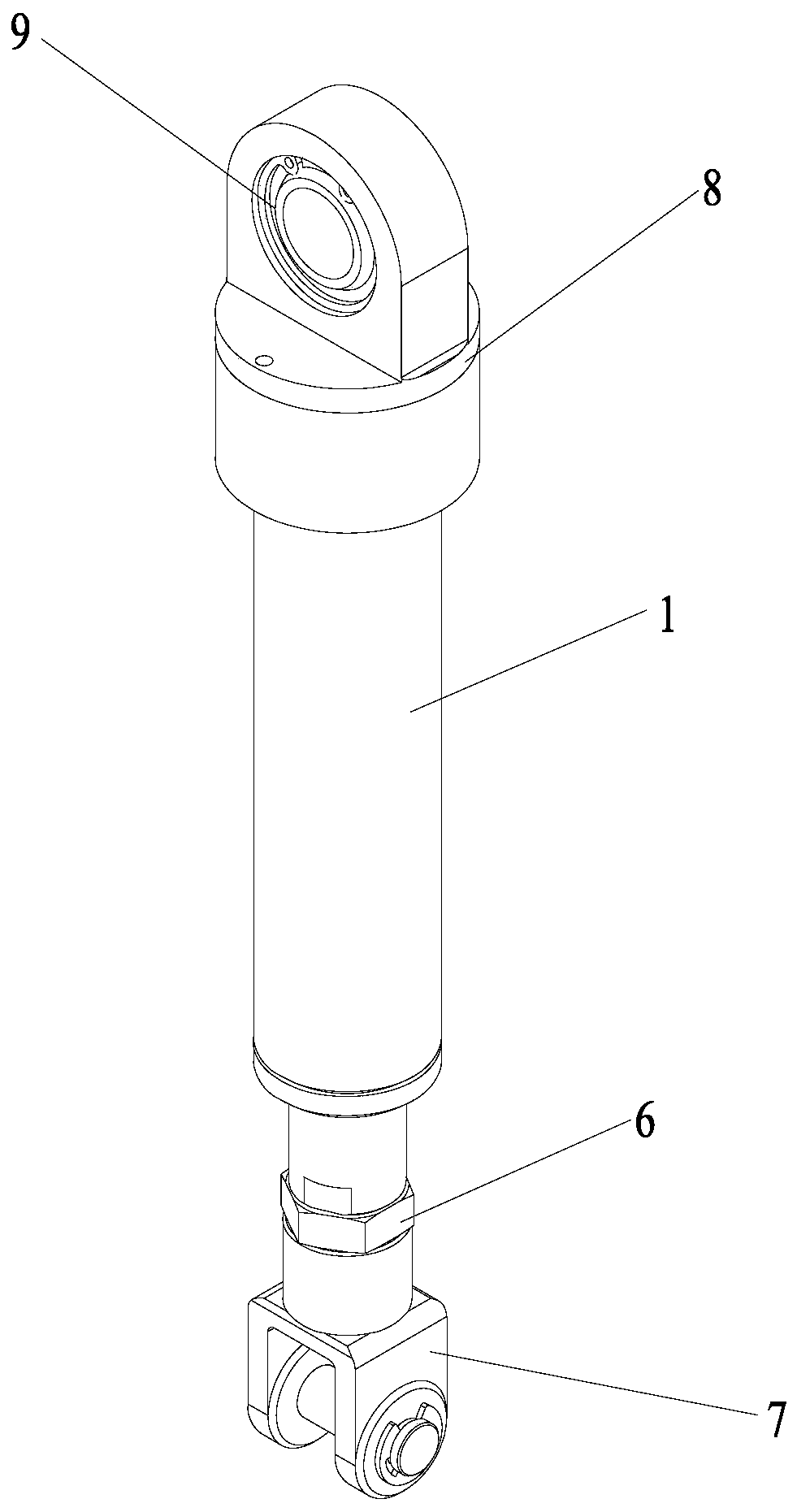

[0015] Figure 1~3 Including piston cylinder 1, limit step 1-1, disc spring group 2, disc spring 201, slip ring 3, guide sleeve 4, piston rod 5, lock nut 6, Y-shaped joint 7, base 8, joint bearing 9, jump ring 10 etc.

[0016] Such as Figure 1~3 As shown, the present invention is a mobile robot shock absorber, comprising a piston cylinder 1, one axial end of the piston cylinder 1 is fixedly connected to a base 8, a disc spring group 2 is arranged in the inner cavity of the piston cylinder 1, and the piston rod 5 is slidably fitted. Connected to the inner hole of the piston barrel 1, the piston rod 5 extends into the piston head of the inner hole of the piston barrel 1 to set a ring groove, the slip ring 3 is connected to the ring groove, and the piston head of the piston rod 5 passes through the piston barrel 1 The limit step 1-1 limit o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com