Preparation method and product of array sensor of bridged micro-nano structure sensing unit

An array sensor and micro-nano structure technology, applied in the direction of material electrochemical variables, etc., to achieve the effects of improving sensitivity, reducing high junction resistance, and strong fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

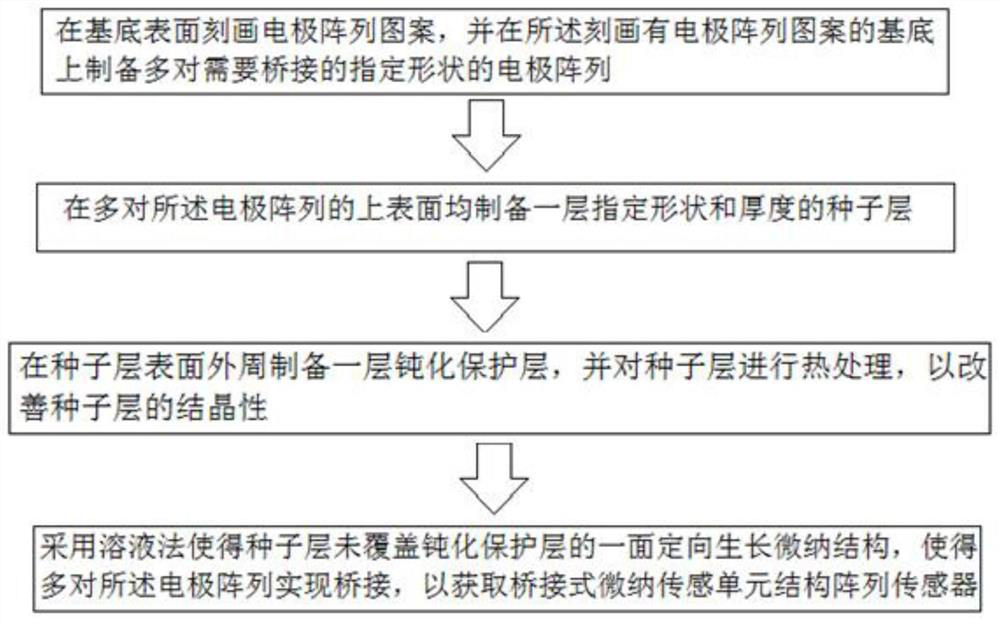

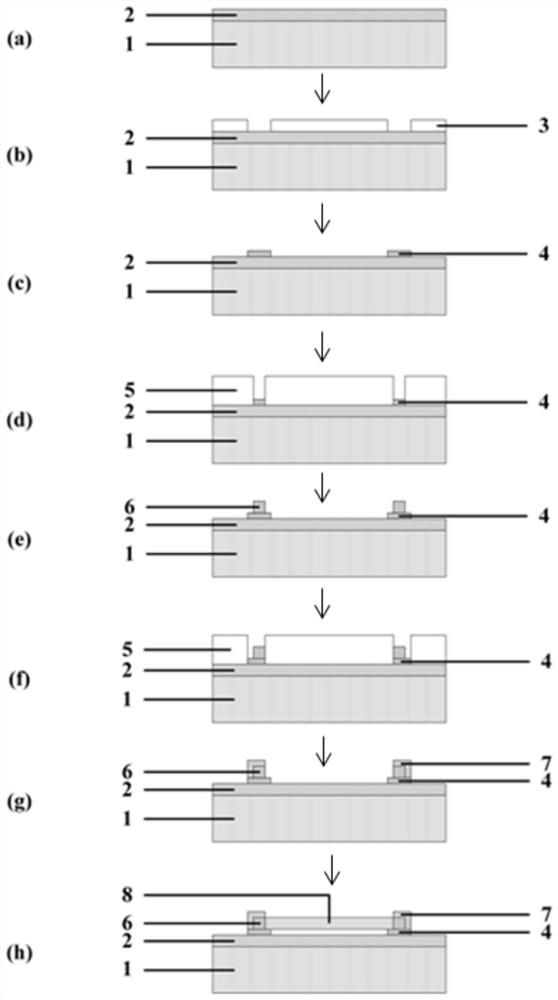

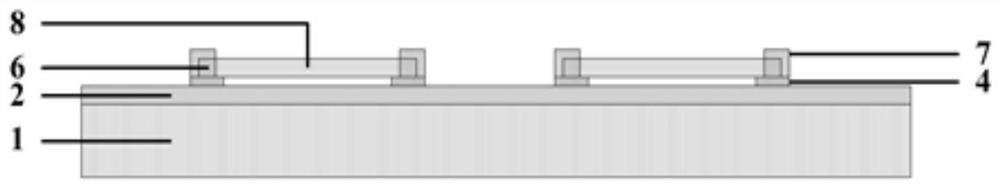

[0038] Such as figure 1 with figure 2 As shown, the present invention provides a method for preparing an array sensor of a bridged micro-nano structure sensing unit, which specifically includes the following steps:

[0039] S1 Writing an electrode array pattern on the surface of the substrate, and preparing multiple pairs of electrode arrays 4 of a specified shape that need to be bridged on the substrate with the electrode array pattern drawn.

[0040] Specifically, the electrode array pattern is prepared on the surface of the substrate by photolithography, and the electrode array 4 is prepared on the surface of the substrate by deposition and solution stripping. However, in the present invention, it is not limited to photolithography, deposition and solution stripping. Any technical means and method that can realize the preparation of multiple pairs of electrode arrays 4 of a specified shape that need to be bridged on the substrate in this solution can be used. Furthermore...

Embodiment 1

[0060] S1 uses AZ5214 photoresist as a thin glue to prepare a square-based electrode array pattern on the surface of the substrate;

[0061] S2 uses magnetron sputtering to prepare an Au electrode array on the surface of the substrate and uses a degumming solution to peel off the metal electrodes;

[0062] S3 uses overlay technology to prepare the seed layer pattern of the micro-nano structure sensing unit on the surface of the substrate and the electrode, that is, the pattern of the bridge pier, and the shape is square;

[0063] S4 Prepare the seed layer ZnO of the micro-nano structure sensing unit on the surface of the substrate by means of electron beam evaporation, and perform stripping by solution method, remove the photoresist, and obtain the seed layer ZnO of the micro-nano structure sensing unit on the electrode;

[0064] S5 uses NR21-20000P as a thick glue to carry out photolithography to prepare a passivation protective layer pattern on the seed layer of the electrod...

Embodiment 2

[0070] S1 uses HTI751 photoresist as a thin glue to prepare a rectangular-based electrode array pattern on the surface of the substrate;

[0071] S2 uses thermal evaporation to prepare an Ag electrode array on the surface of the substrate and uses a degumming solution to peel off the metal electrodes;

[0072] S3 uses overlay technology to prepare the seed layer pattern of the micro-nano structure sensing unit on the surface of the substrate and the electrode, that is, the pattern of the bridge pier, and the shape is rectangular;

[0073] S4 Prepare the seed layer Cu of the micro-nano structure sensing unit on the surface of the substrate by magnetron sputtering, and perform stripping by solution method, remove the photoresist, and obtain the seed layer Cu of the micro-nano structure sensing unit on the electrode;

[0074] S5 uses NR26-25000P as a thick glue for photolithography to prepare a passivation protective layer pattern on the seed layer of the electrode and micro-nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com