Ultrasonic driving power supply for automatically tracking series resonance frequency of transducer

A series resonance, driving power technology, applied in the fluid, electrical measuring instrument parts, instruments and other directions that use vibration, can solve the problem of frequency tracking of transducers, there is no good solution, the filter can not meet the requirements of use, dynamic Resistance has a huge influence and other problems, so as to improve the accuracy of phase detection, realize digital frequency control, and avoid frequency drift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

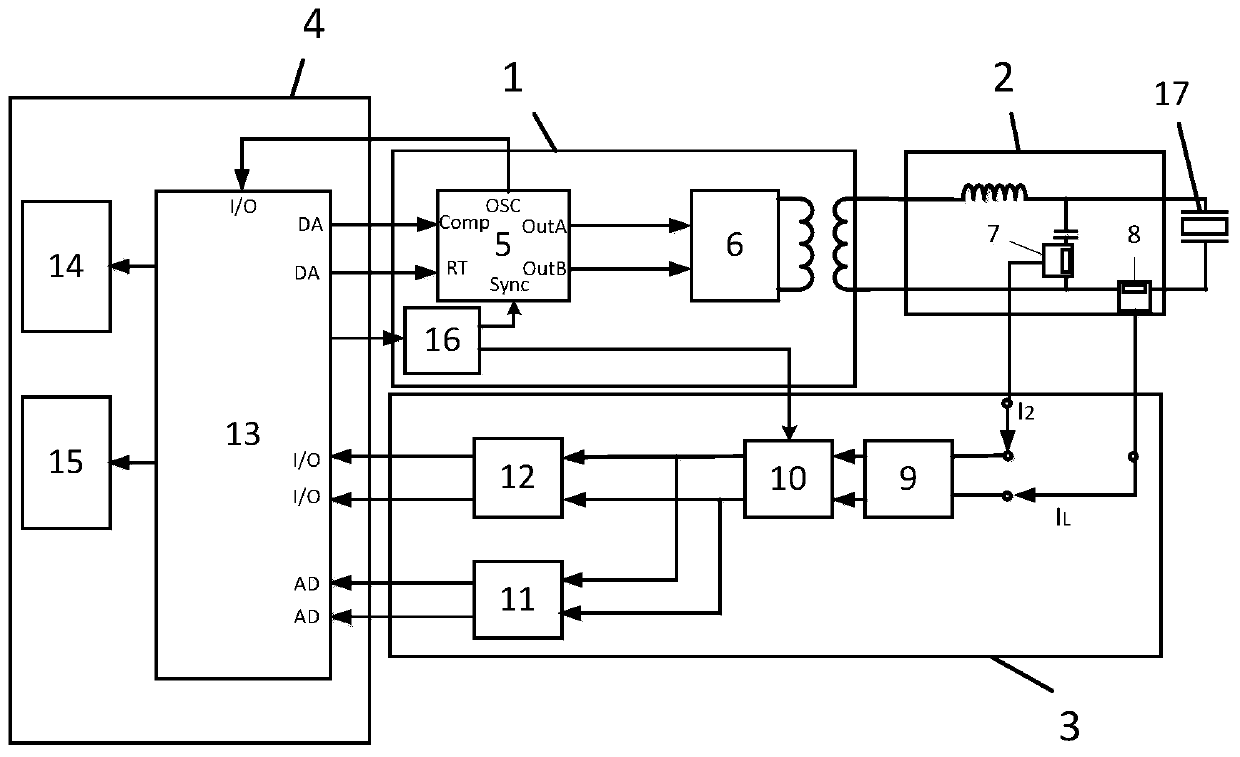

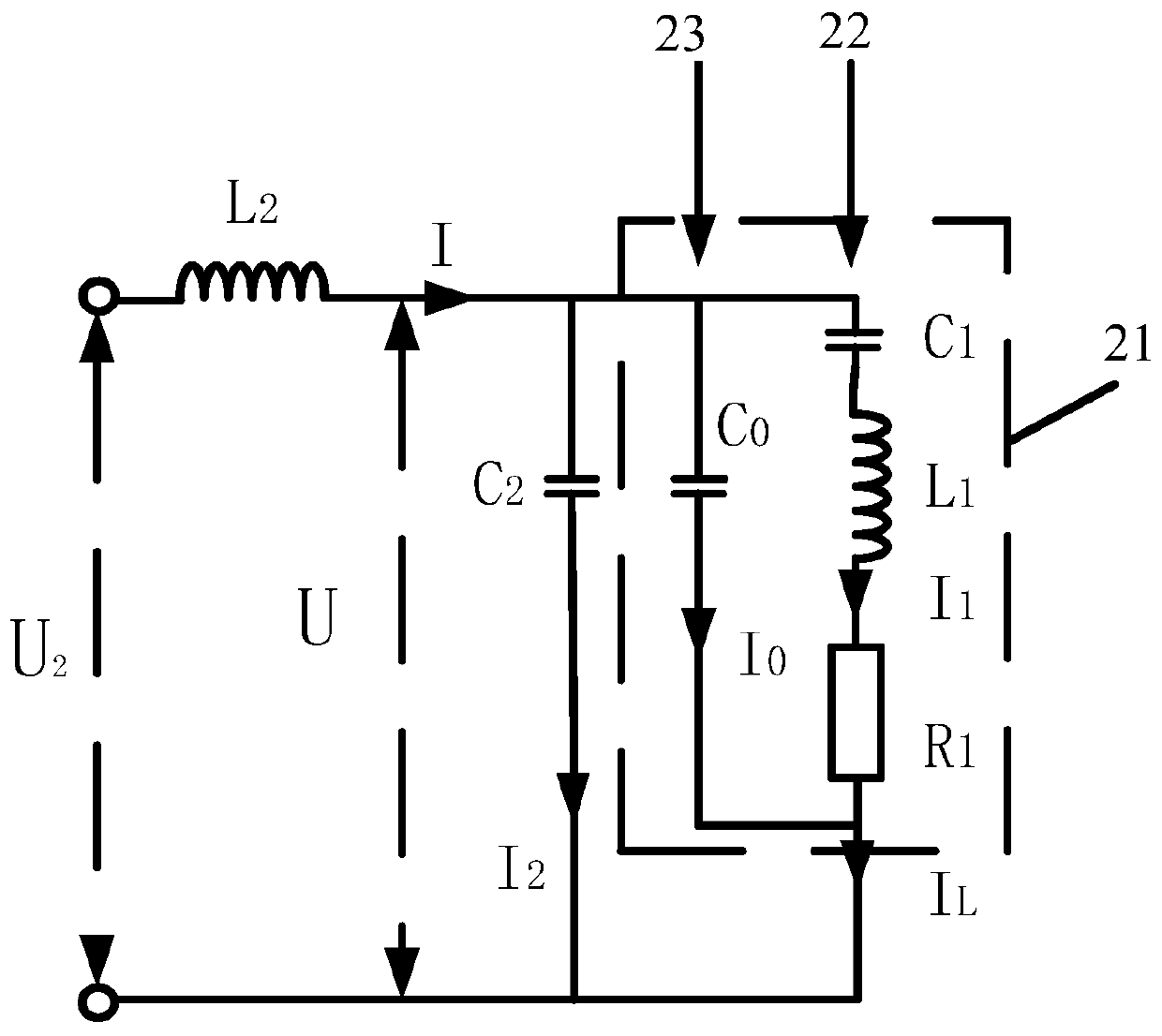

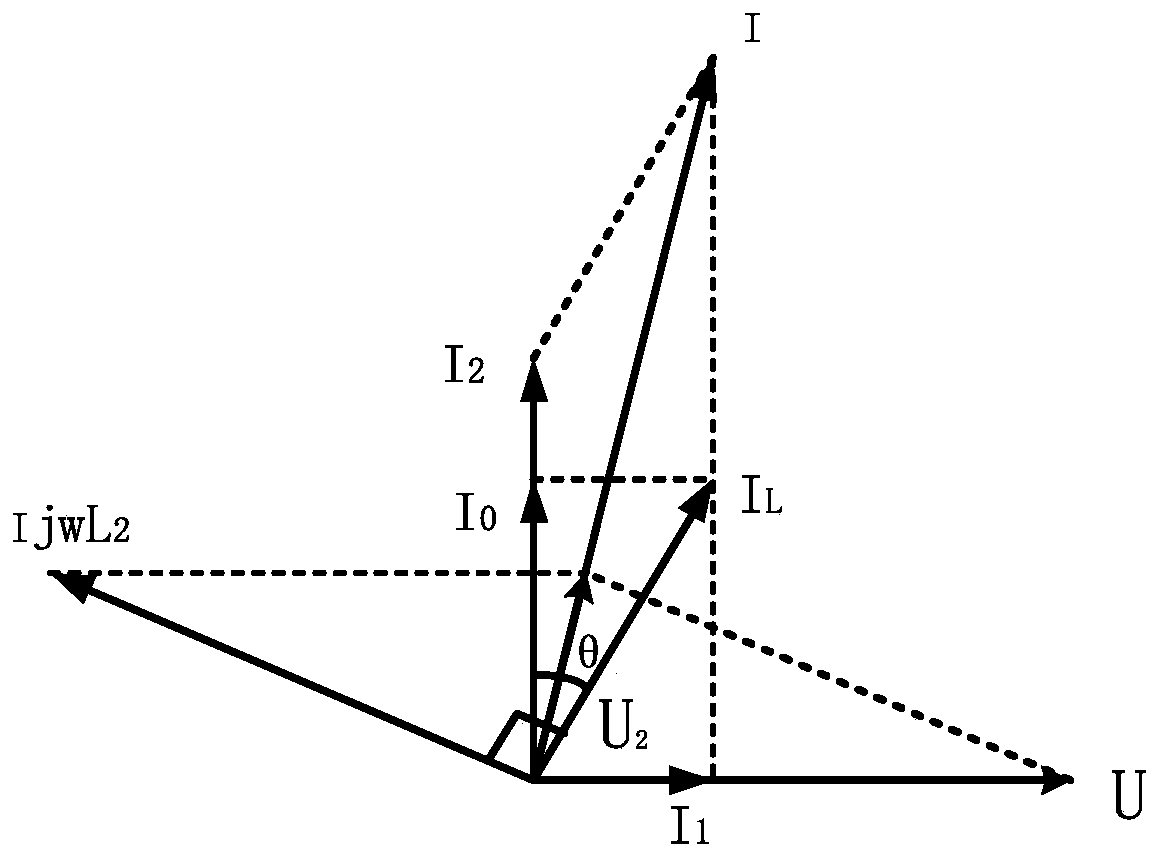

[0053] In order to overcome the above-mentioned shortcomings of the prior art, the present invention aims at the characteristics of the piezoelectric ultrasonic transducer, and on the basis of the existing separately excited ultrasonic power supply, designs a driving power supply with dual current sampling and precise frequency control, and A real-time tracking method for the series resonance frequency of the transducer is proposed, and an ultrasonic drive power supply that automatically tracks the series resonance frequency of the transducer is realized.

[0054] The technical scheme adopted by the present invention is an ultrasonic driving power supply for automatically tracking the series resonance frequency of the transducer, which includes the following four parts;

[0055] The first part is the drive circuit, such as figure 1 As shown, it includes a PWM wave generating circuit and a half-bridge inverter circuit 6 . The PWM (PulseWidth Modulation) wave generation unit is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com