Aramid fiber coating liquid and preparation method thereof, diaphragm and application based on aramid fiber coating liquid

A technology of coating liquid and aramid fiber, which is applied to structural parts, electrical components, battery pack parts, etc., can solve the problems of time-consuming and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

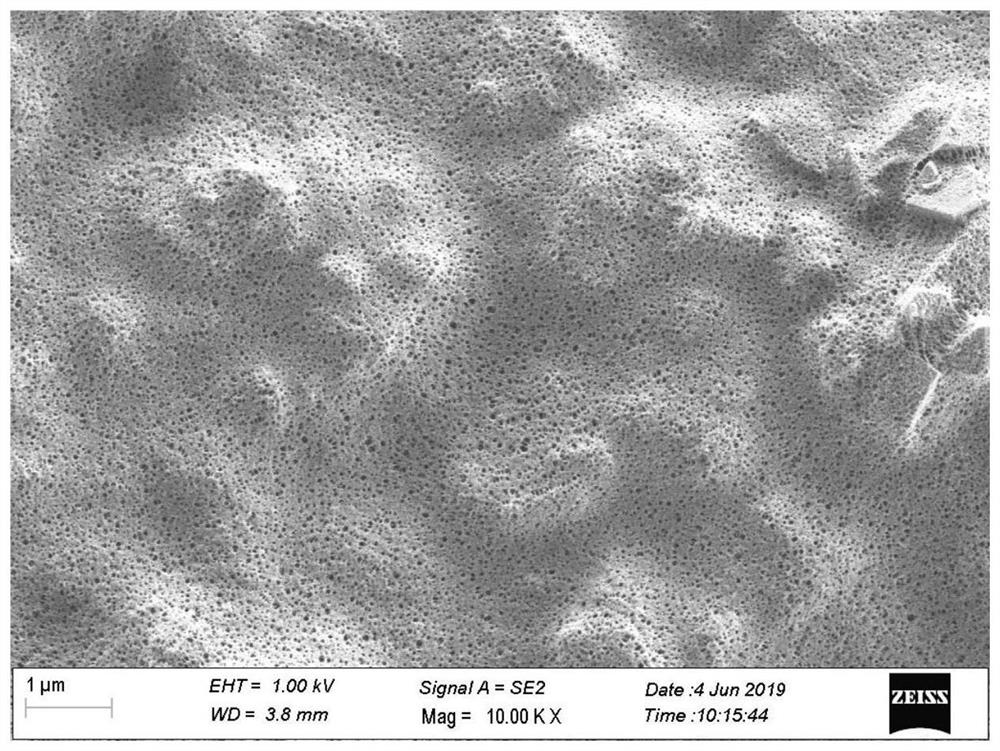

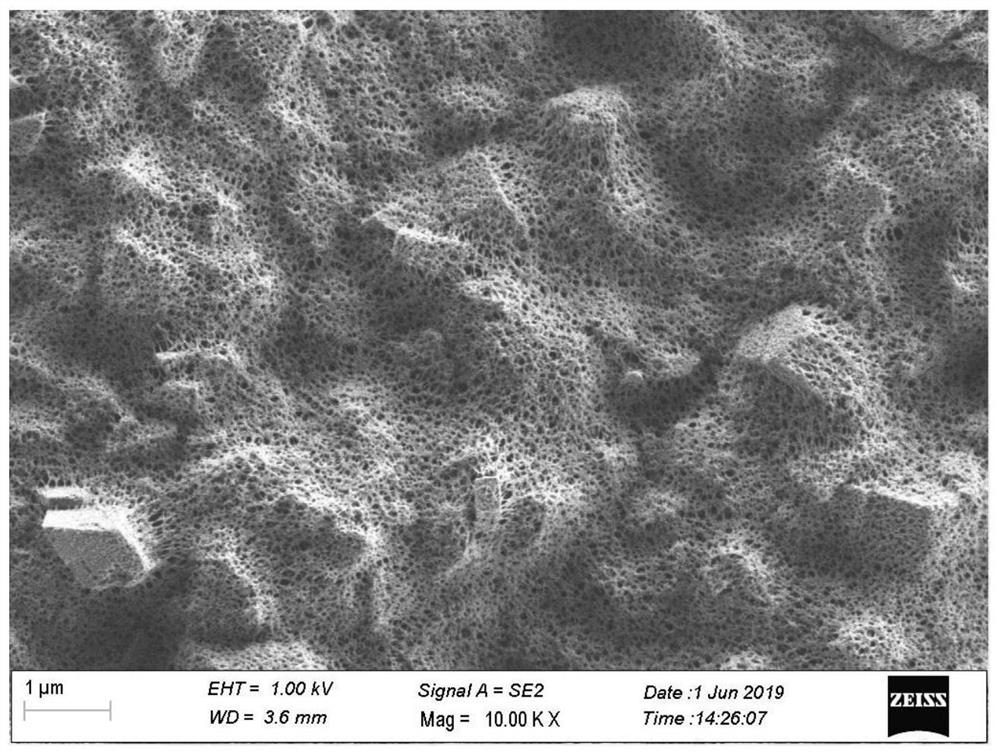

Image

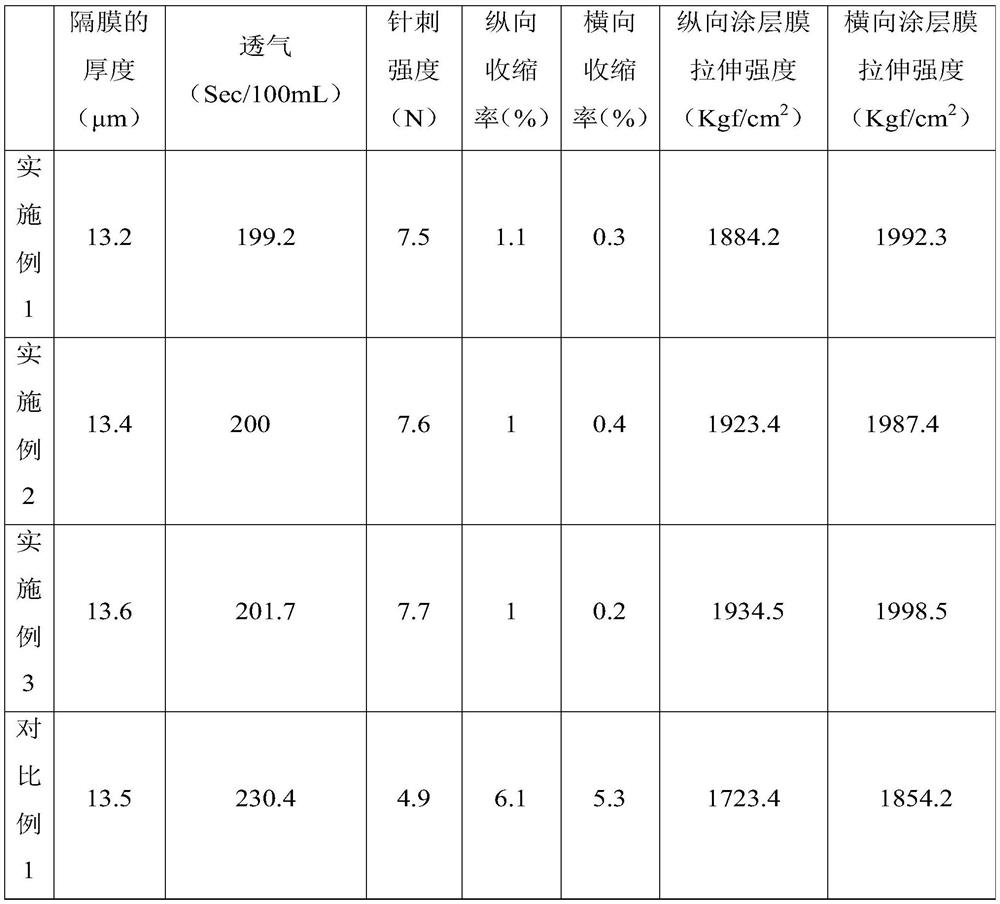

Examples

Embodiment 1

[0036] A preparation method for an aramid fiber coating solution, comprising the following steps:

[0037] 1) Mix ceramic particles (alumina) with dimethylacetamide (DMAc) and stir for 30 minutes. Grinding with pin-type nano sand mill for 20min to obtain the first mixture, wherein the speed of sand milling is 900r / min, and the ratio of ceramic particles to dimethylacetamide is 15:70 in parts by mass; In the test, the particle size of the ceramic particles in the first mixture is D50: 0.3 μm, D90: 1 μm.

[0038] 2) Under a nitrogen atmosphere, stir the first mixture and m-phenylenediamine for 20 minutes, after stirring, cool down to 0°C in a chilled water bath, then add isophthaloyl chloride, and stir for 20 minutes (the temperature of this process is 0°C ), remove the water bath, then heat up to 80°C, and the heating rate is 6°C / min, add calcium hydroxide, and stir for 30min (the process temperature is 80°C), to obtain the second mixture, wherein, in parts by mass, the - The...

Embodiment 2

[0041] A preparation method for an aramid fiber coating solution, comprising the following steps:

[0042] 1) Mix ceramic particles (silicon dioxide) with dimethylacetamide (DMAc) and stir for 30 minutes. The first mixture was obtained by sanding with a pin-type nano-sand mill for 20 minutes, wherein the rotational speed of the sand mill was 900r / min, and the ratio of ceramic particles to dimethylacetamide was 17:75 in parts by mass; In the test, the particle size of the ceramic particles in the first mixture is D50: 0.5 μm, D90: 1.2 μm.

[0043] 2) Under a nitrogen atmosphere, stir the first mixture and m-phenylenediamine for 20 minutes, after stirring, cool down to 2°C in a chilled water bath, then add isophthaloyl chloride, and stir for 20 minutes (the temperature of this process is 2°C ), remove the water bath, then heat up to 80°C, and the heating rate is 7°C / min, add calcium hydroxide, and stir for 30min (the process temperature is 80°C), to obtain the second mixture, w...

Embodiment 3

[0046] A preparation method for an aramid fiber coating solution, comprising the following steps:

[0047] 1) Mix ceramic particles (barium titanate) with dimethylacetamide (DMAc), and stir for 30 minutes. The first mixture was obtained by using a pin-type nano-sand mill for 20 minutes, wherein the rotational speed of the sand mill was 900r / min, and the ratio of ceramic particles to dimethylacetamide was 20:80 in parts by mass; In the test, the particle size of the ceramic particles in the first mixture is D50: 0.6 μm, D90: 1.3 μm.

[0048] 2) Under a nitrogen atmosphere, stir the first mixture and m-phenylenediamine for 20 minutes, then cool down to 5°C in a chilled water bath after stirring, then add isophthaloyl chloride, and stir for 20 minutes (the process temperature is 5°C ), remove the water bath, then heat up to 80°C, and the heating rate is 8°C / min, add calcium hydroxide, and stir for 30min (the process temperature is 80°C), to obtain the second mixture, wherein, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com