Low-cost polyolefin synthetic paper

A technology for synthetic paper and metallocene polyethylene, applied in synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve problems such as inability to meet, low needle punching strength and tensile strength, and achieve low cost , Good acupuncture strength and tensile strength, improve the effect of acupuncture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

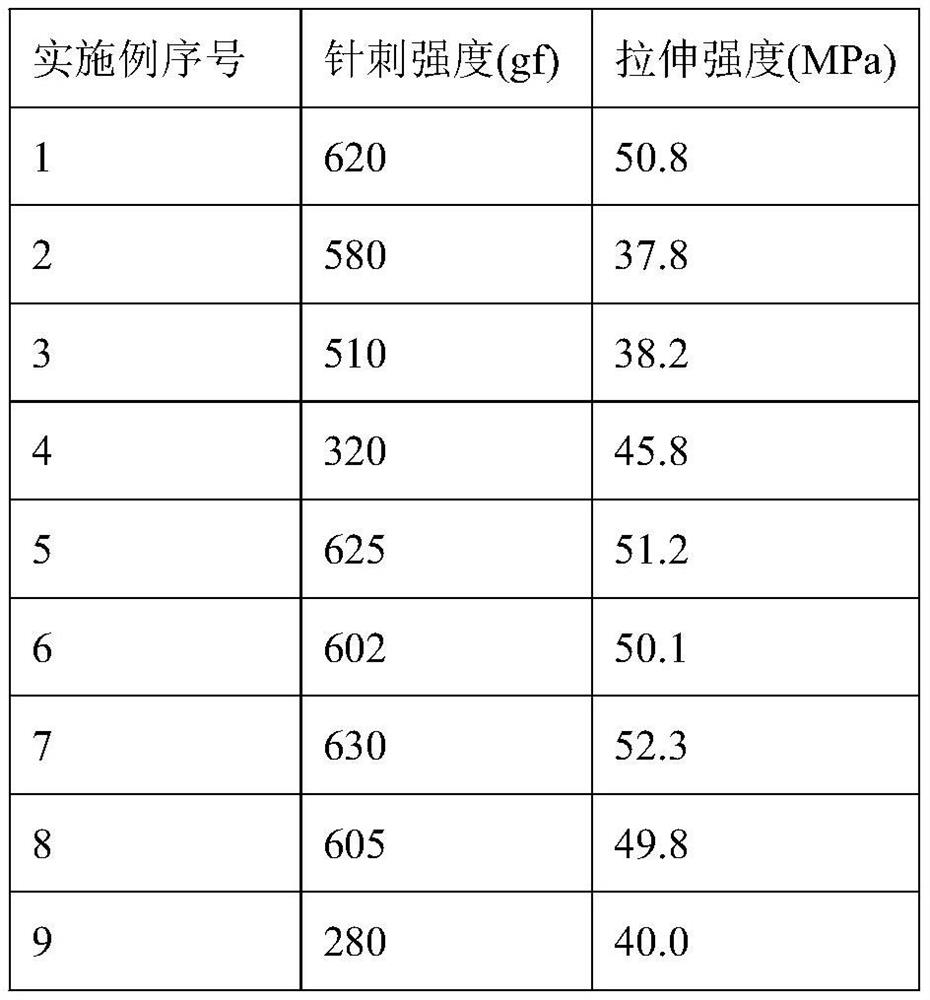

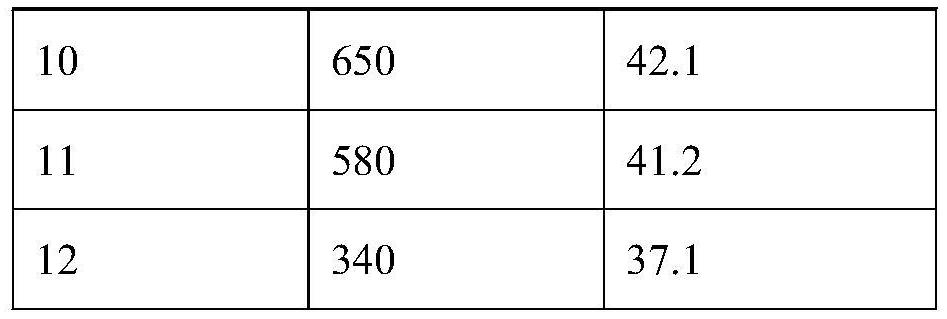

Examples

preparation example Construction

[0023] The preparation method of the hyperbranched polypropylene butene copolymer is as follows: propylene butene is catalyzed by an ethylene acenaphthylene (α-diimine) nickel catalyst, and a chain transfer agent is added to polymerize to obtain the hyperbranched polypropylene butene copolymer.

[0024] Polyamide A: prepared from terephthalic acid and succinic acid.

[0025] Polyamide B: prepared from p-phenylenediamine and adipic acid.

[0026] The inorganic filler is silicon dioxide; the foaming agent is polytrimethylene terephthalate.

Embodiment 1

[0028] The composition of the upper surface layer and the lower surface layer includes: 20 parts of metallocene polyethylene, 20 parts of polyamide A, 5 parts of inorganic filler, and the thickness is 20um;

[0029] The composition of the upper surface layer and the lower surface layer includes: 35 parts of hyperbranched polypropylene-butene copolymer, 35 parts of propylene terpolymer A, 8 parts of inorganic filler, and the thickness is 30um;

[0030] The core layer is 45 parts of isotactic polypropylene, the thickness is 20um, and 10 parts of foaming agent.

Embodiment 2

[0032] Same as Example 1, except that metallocene polyethylene is replaced by common polyethylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com