Fixing base for laser diode patch

A technology of laser diodes and fixed bases, which is applied to lasers, laser components, semiconductor lasers, etc., can solve the problems of inability to transmit multiple channels, poor monochromaticity, and low output power, and achieve good lighting effect and large irradiation area The effect of wide and easy patch work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

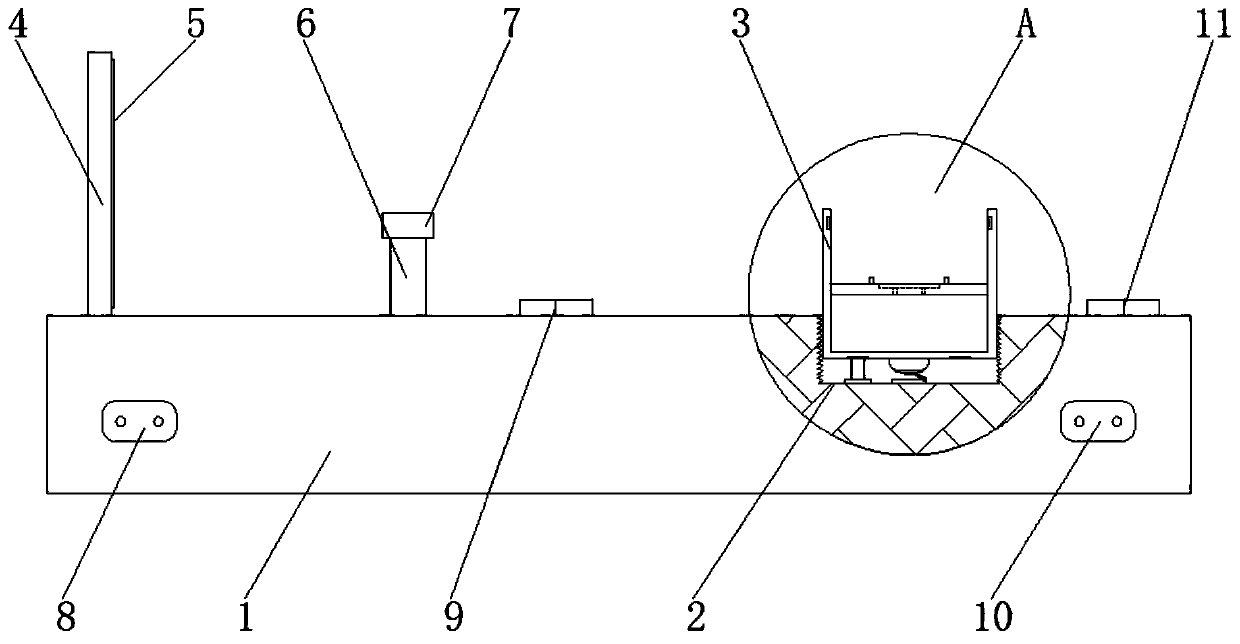

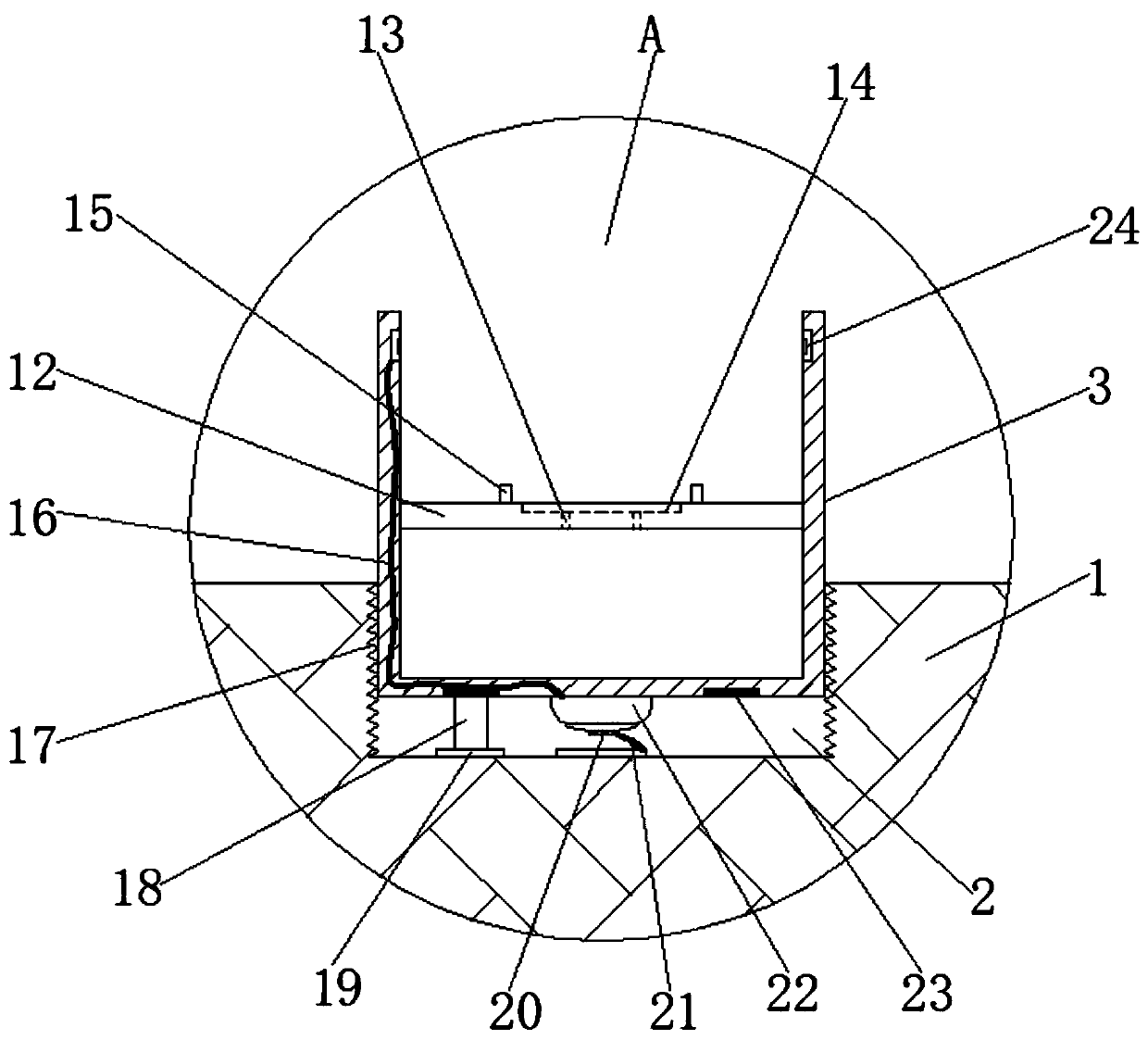

[0028] see Figure 1-4 , the present invention provides a technical solution: a fixed base for a laser diode patch, including a base 1 and a fixing groove 2, the fixing groove 2 is arranged on the right upper end surface of the base 1, and the inner surface of the base 1 The surface of the ring is provided with threads 17, and the upper end of the base 1 is provided with a fixing device and a detection device;

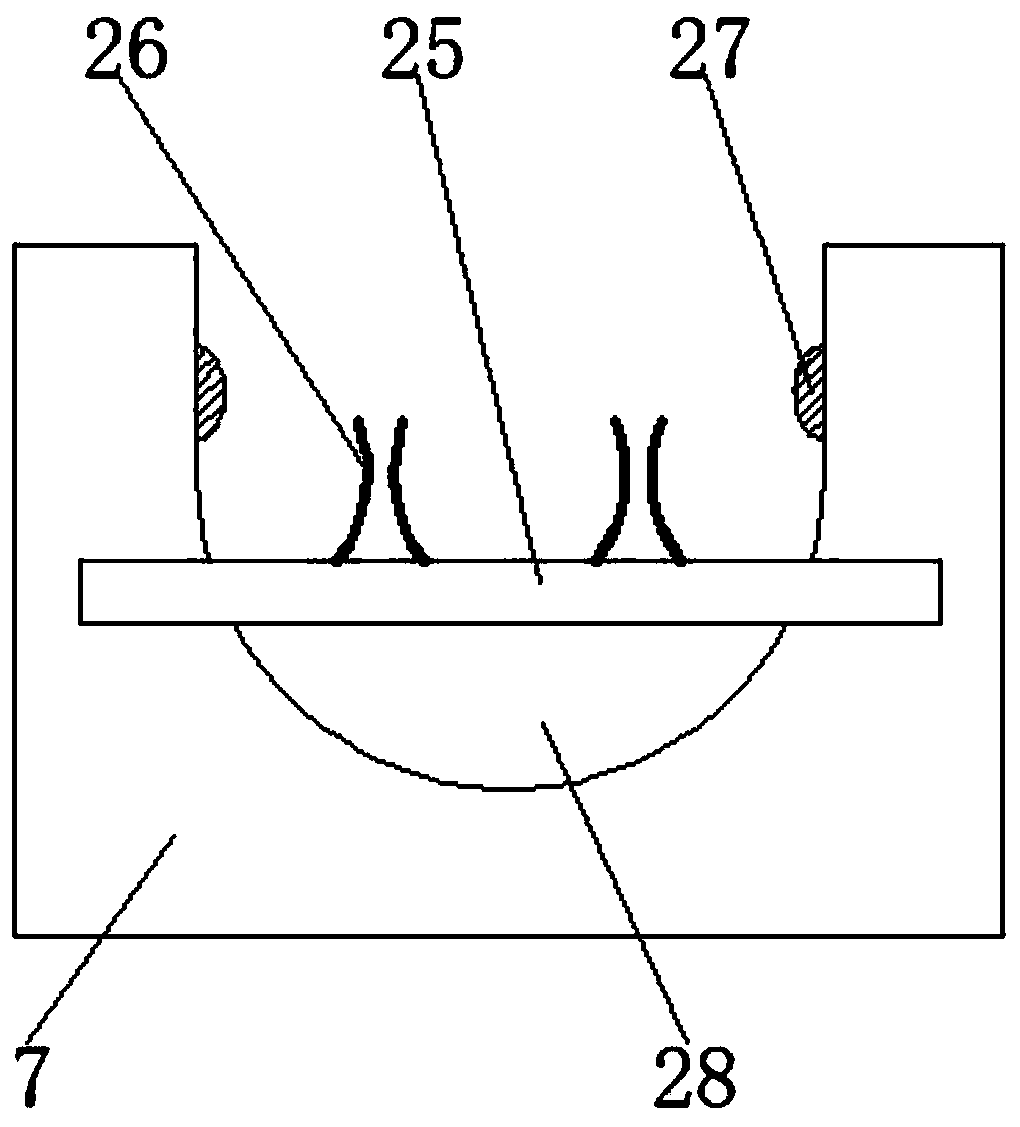

[0029] The fixing device includes a fixing seat 3, an LED strip 24, a separator 12, a card slot 14, a positive contact 22, a slip ring 23, a brush piece 18 and a spring copper piece 21; the fixing seat 3 is screwed and fixed on the In the fixed groove 2, and the middle part of the surface of the fixed groove 2 is fixed with a spring coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com