A kind of cus/carbon black composite photothermal conversion material and preparation method thereof

A composite light and heat conversion technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, fibrous fillers, etc., can solve the conditions for carbon material preparation and functionalization, photothermal conversion efficiency It can reduce the problems of low photothermal stability and low photothermal stability, and achieve the effects of high photothermal conversion efficiency, easy material composition, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

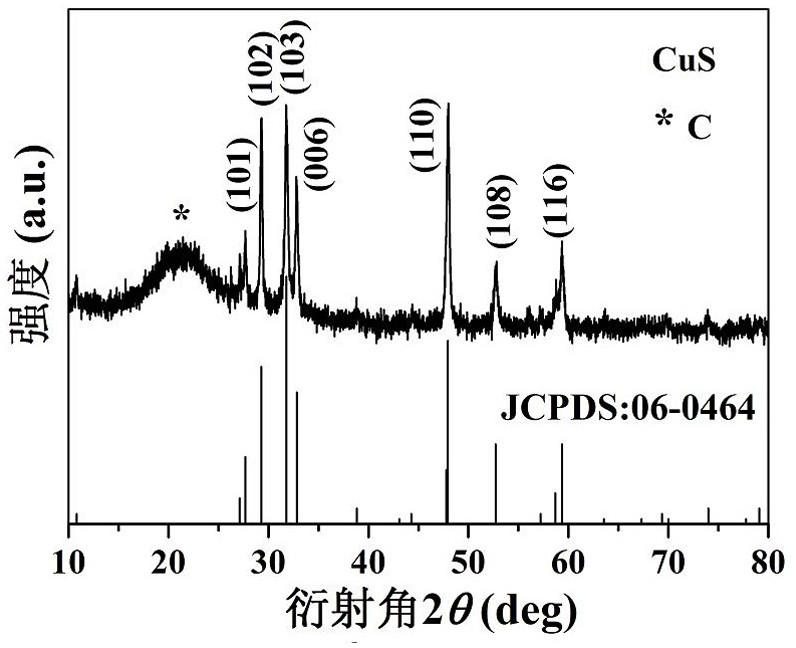

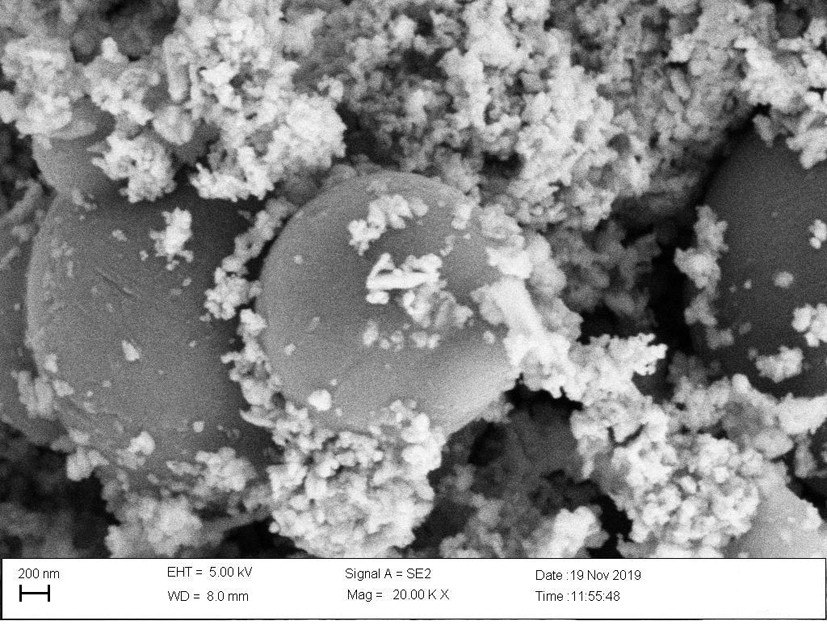

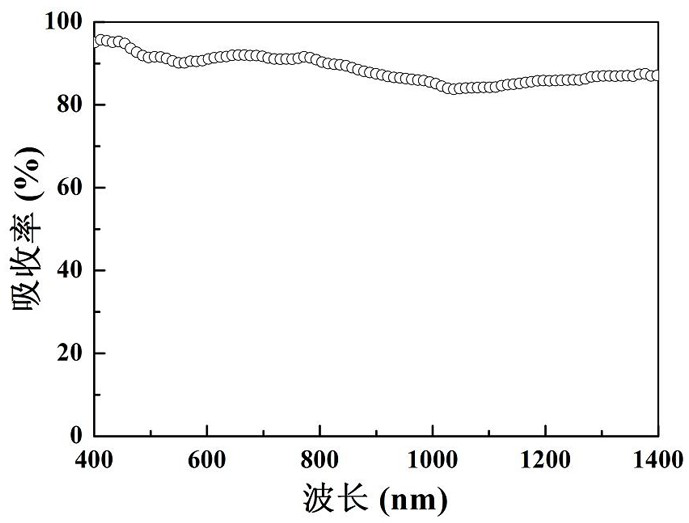

[0021] A kind of CuS / carbon black composite photothermal conversion material of the present invention, its chemical formula is (1-x)CuS / xC, wherein x is the percentage of the total mass of carbon black mass, in this example, x=20%, the photothermal The specific preparation steps of the conversion material are as follows:

[0022] 1) Weigh 1.3445g (10mmol) of CuCl respectively 2 ·H 2 O, 4.4674 g (18 mmol) Na 2 S 2 O 3 ·5H 2 O, 0.5975 g (3.32 mmol) of glucose was dissolved in 20 mL of distilled water, and stirred evenly to obtain solution A. During the stirring process, 15 mL of ethylene glycol was added dropwise to solution A to obtain yellow-green suspension B.

[0023] 2) Transfer the suspension B to the reaction kettle, add distilled water to fill up to 80% of the volume of the reaction kettle, and then put the reaction kettle into an oven for hydrothermal treatment at a temperature of 180 °C for 6 hours.

[0024] 3) After the hydrothermal treatment reaction of Suspens...

Embodiment 2

[0029] The CuS / carbon black composite photothermal conversion material of the present invention has the chemical formula (1-x)CuS / xC, wherein x is the percentage of the carbon black mass in the total mass, and in this example, x=10%. Its specific preparation steps are as follows:

[0030] 1) Weigh 1.3445g (10mmol) of CuCl respectively 2 ·H 2 O, 4.9638 g (20 mmol) Na 2 S 2 O 3 ·5H 2 O, 0.2655g (1.47mmol) of glucose was dissolved in 25mL of distilled water and stirred well to obtain solution A. During the stirring process, 10mL of ethylene glycol was added dropwise to solution A to obtain yellow-green suspension B;

[0031] 2) Transfer the suspension B to the reaction kettle, add distilled water to fill up to 75% of the volume of the reaction kettle, put the reaction kettle into an oven, and perform hydrothermal treatment at 160°C for 8 hours;

[0032] 3) After the hydrothermal treatment reaction of suspension B is completed, it is naturally cooled to room temperature, and...

Embodiment 3

[0034] A CuS / carbon black composite photothermal conversion material of the present invention has a chemical formula of (1-x)CuS / xC, wherein x is the percentage of the carbon black mass in the total mass, and in this example, x=30%. Its specific preparation steps are as follows:

[0035] 1) Weigh 1.3445g (10mmol) of CuCl respectively 2 ·H 2 O, 3.7228 g (15 mmol) Na 2 S 2 O 3 ·5H 2 O, 1.0243g (5.68mmol) of glucose was dissolved in 15mL of distilled water, and stirred evenly to obtain solution A. During the stirring process, 10mL of ethylene glycol was added dropwise to solution A to obtain yellow-green suspension B;

[0036] 2) Transfer the suspension B to the reaction kettle, add distilled water to fill up to 80% of the volume of the reaction kettle, put the reaction kettle into an oven and perform hydrothermal treatment at 170°C for 7 hours.

[0037]3) After the hydrothermal treatment reaction of Suspension B was completed, it was naturally cooled to room temperature, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com