Manufacturing method of high-elasticity pressure-sensitive adhesive for reflective film

A manufacturing method and high-elasticity technology, applied in pressure-sensitive films/sheets, film/sheet-like adhesives, adhesives, etc., can solve problems such as poor resilience and toughness, achieve excellent impact resistance and rebound, improve the use of The effect of life, excellent tack and retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

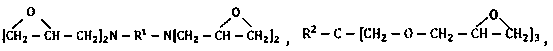

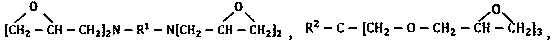

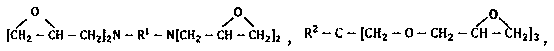

Method used

Image

Examples

Embodiment 1

[0069] A method for manufacturing a high-elastic pressure-sensitive adhesive for a reflective film, comprising the following components by weight:

[0070] 100 parts of poly(meth)acrylic acid copolymer,

[0071] 1.5 parts of reactive liquid nitrile rubber,

[0072] 0.1 part of epoxy crosslinking agent,

[0073] 5 parts of expanded microspheres,

[0074] 45 parts of organic solvent,

[0075] Described organic solvent is the mixture of one or two kinds of ester solvent or ketone solvent, and its manufacture method is:

[0076] Q1: At room temperature, take the organic solvent and poly(meth)acrylic acid copolymer in the above weight ratio and put them into a high-speed mixer for pre-dispersion treatment, and stir for 20 minutes at a stirring speed of 800r / min to obtain dispersion A;

[0077] Q2: Take the reactive liquid nitrile rubber and expanded microspheres in the above weight ratio and add them to the dispersion A and continue to stir for 30 minutes to obtain the dispersi...

Embodiment 2

[0108] A method for manufacturing a high-elastic pressure-sensitive adhesive for a reflective film, comprising the following components by weight:

[0109] 100 parts of poly(meth)acrylic acid copolymer,

[0110] 10 parts of reactive liquid nitrile rubber,

[0111] 0.8 part of epoxy crosslinking agent,

[0112] 10 parts of expanded microspheres,

[0113] 60 parts of organic solvent,

[0114] Described organic solvent is the mixture of one or two kinds of ester solvent or ketone solvent, and its manufacture method is:

[0115] Q1: At room temperature, take the organic solvent and poly(meth)acrylic acid copolymer in the above weight ratio and put them into a high-speed mixer for pre-dispersion treatment, and stir for 30 minutes at a stirring speed of 1500r / min to obtain dispersion A;

[0116] Q2: Take the reactive liquid nitrile rubber and expanded microspheres in the above weight ratio and add them to the dispersion A and continue to stir for 30 minutes to obtain the dispers...

Embodiment 3

[0147] A method for manufacturing a high-elastic pressure-sensitive adhesive for a reflective film, comprising the following components by weight:

[0148] 100 parts of poly(meth)acrylic acid copolymer,

[0149] Reactive liquid nitrile rubber 5.8 parts,

[0150] 0.45 parts of epoxy cross-linking agent,

[0151] 7.5 parts of expanded microspheres,

[0152] 52.5 parts of organic solvent,

[0153] Described organic solvent is the mixture of one or two kinds of ester solvent or ketone solvent, and its manufacture method is:

[0154] Q1: At room temperature, take the organic solvent and poly(meth)acrylic acid copolymer in the above weight ratio and put them into a high-speed mixer for pre-dispersion treatment, and stir for 25 minutes at a stirring speed of 1150r / min to obtain dispersion A;

[0155] Q2: Take the reactive liquid nitrile rubber and expanded microspheres in the above weight ratio and add them to the dispersion A and continue to stir for 30 minutes to obtain the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com