Apparatus and method for composite material thrust bearing online monitoring oil film temperature

A technology of composite materials and thrust bearings, applied in measuring devices, applications of thermometers, parts of thermometers, etc., can solve the problem of large temperature measurement errors of tile bodies, accidents caused by alarm delays, and inability to timely and accurately monitor the thrust of composite materials Bearing oil film temperature and other issues, to achieve a good sealing effect, to ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

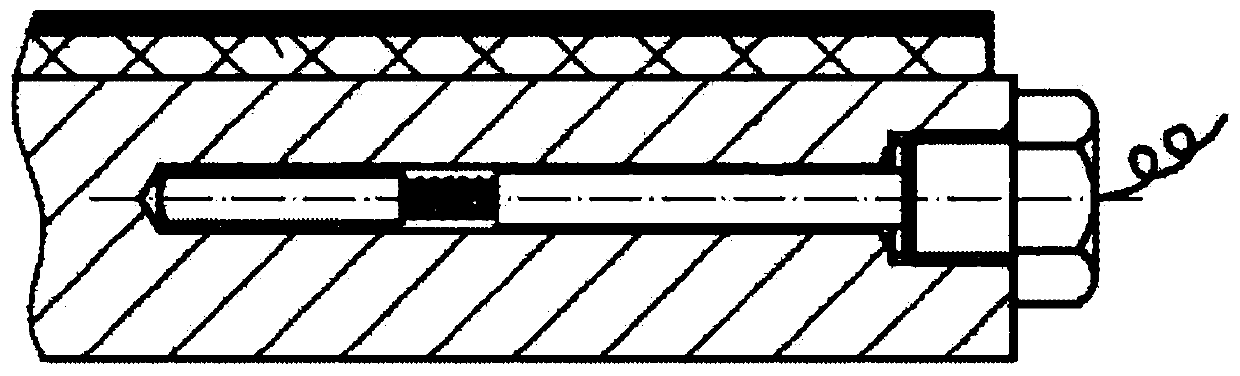

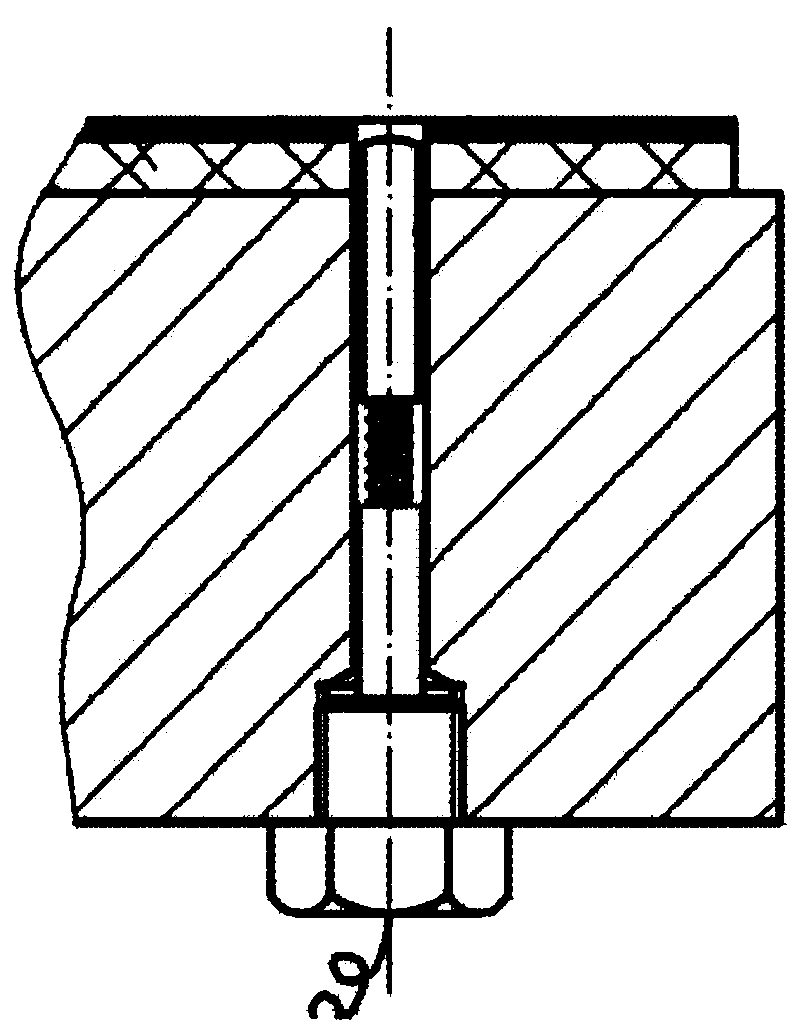

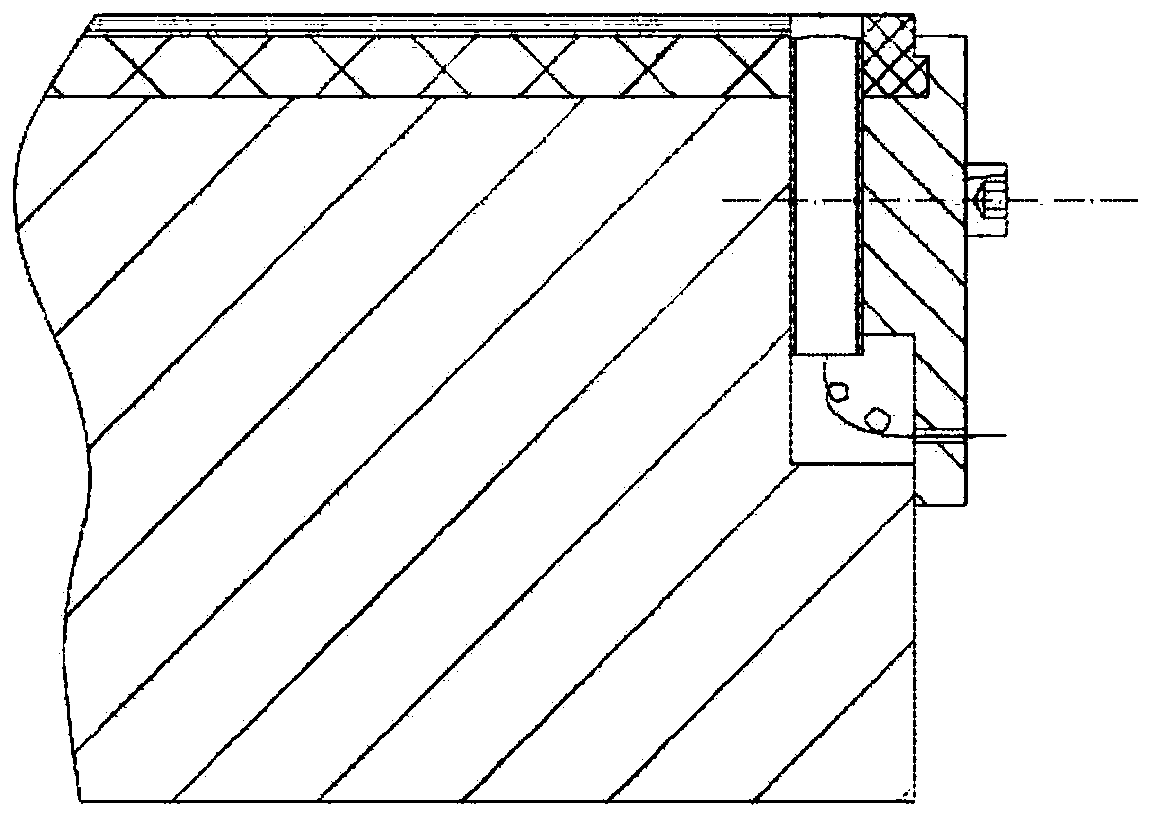

[0052] Such as Figure 5-6 As shown, the present invention provides a device for online monitoring of oil film temperature of a composite material thrust bearing, comprising a composite material thrust bearing and an on-line monitoring oil film temperature assembly, the composite material thrust bearing mainly consists of a shoe base 1 and a composite material arranged on the shoe base 1 The material tile surface 2 is composed of; the composite material thrust bearing is provided with a tapered stepped installation hole 5 for installing the online monitoring oil film temperature component, the installation hole 5 runs through the tile base 1 and the composite material tile surface 2, and the installation hole 5 axis It is perpendicular to the composite material tile surface 2 and is set at the highest oil film temperature of the composite thrust bearing. The highest oil film temperature of the composite thrust bearing is determined according to the calculation results of the fi...

Embodiment 2

[0058] On the basis of Embodiment 1, the present invention also provides a method for online monitoring of the oil film temperature of a composite thrust bearing, comprising the following steps:

[0059] S1. Set the sensor heat insulation sleeve 4 outside the probe 31 of the oil film temperature sensor 3;

[0060] S2. Evenly apply a sufficient amount of oxygen-resistant sealant on the threaded section 33 of the oil film temperature sensor 3 to ensure that it is completely filled in the tiny gap between the external thread of the threaded section 33 and the internal thread of the threaded hole 52;

[0061] S3. Before the oxygen-resistant sealant is solidified, screw the online monitoring oil film temperature component into the threaded hole 52 of the installation hole 5, the thread is locked, and the sealant solidifies into a tough solid to prevent the thread from moving, so that the component is firmly fixed on the bearing Inside; when installing, ensure that the flange end fa...

Embodiment 3

[0065] Using the composite material thrust bearing and the composite material thrust bearing oil film temperature detection component, the on-line monitoring of the oil film temperature is implemented on the test unit simulating the working condition of the hydroelectric unit. The process is as follows:

[0066] S1. Place 4 sets of sensor heat insulation sleeves outside the probe 31 of the PT100 temperature sensor;

[0067] S2. Evenly apply a sufficient amount of oxygen-resistant sealant on the threaded section 33 of the temperature sensor to ensure that it is completely filled in the tiny gap between the external thread of the threaded section 33 and the internal thread of the threaded hole 52;

[0068] S3. Before the oxygen-resistant sealant is solidified, screw the online monitoring oil film temperature assembly into the bearing installation hole 5, that is, screw the threaded section 33 of the oil film temperature sensor 3 into the thread of the installation hole 5 through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com