Wafer driving device and method

A drying device and drying method technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of peeling displacement of epitaxial wafers, destroying semiconductor structures, reducing wafer yield, quality and reliability, etc., to achieve The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

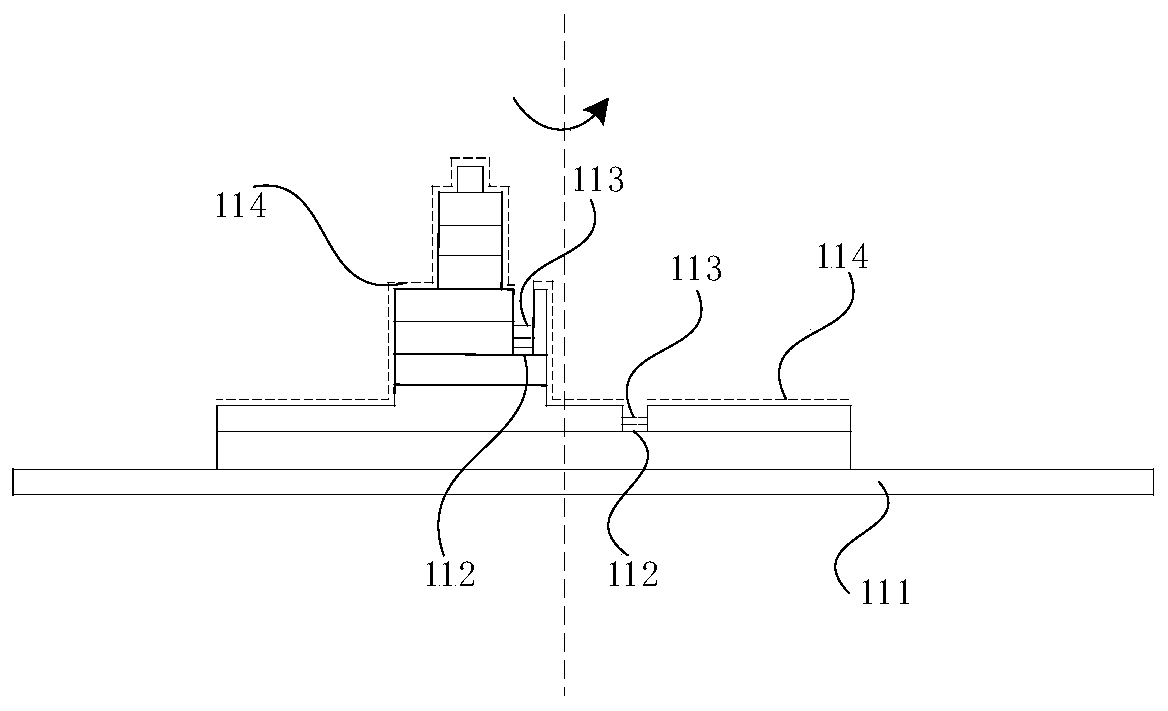

Embodiment 1

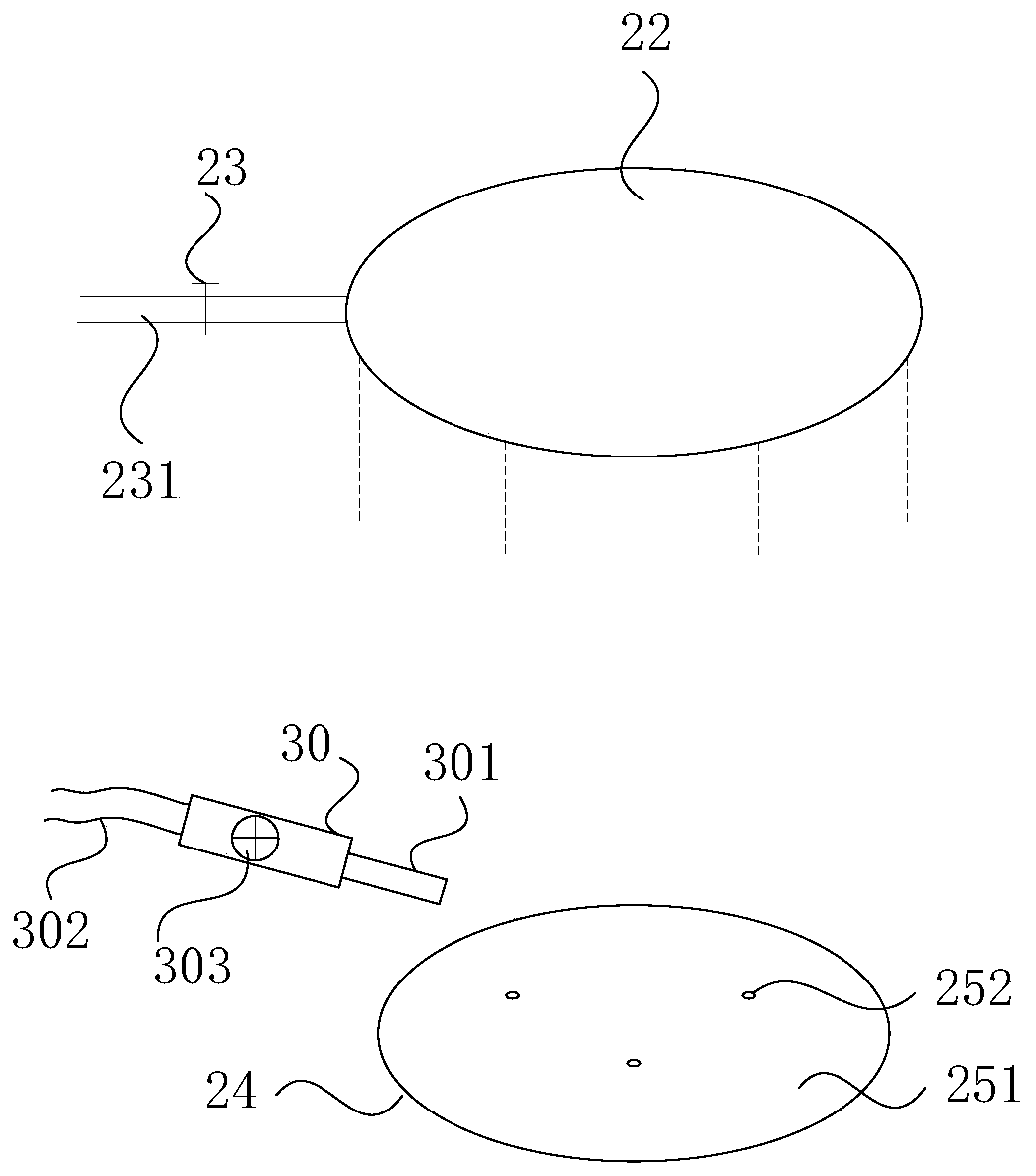

[0046] figure 2 A wafer drying device provided in Embodiment 1 of the present invention specifically includes: a shower head 22 , a vacuum chuck 24 , and a spray gun 30 .

[0047] The shower head 22 is provided with at least one spray hole for spraying cleaning liquid; specifically. The shower head 22 is connected with the liquid inlet pipe 231 to supply cleaning liquid through the liquid inlet pipe 231, wherein the cleaning liquid is isopropanol, and the wafer is cleaned with isopropanol to remove the organic matter on the wafer surface, compared to Other cleaning solutions, such as pure water, can be dried faster, thereby achieving the purpose of quickly drying the wafer. Exemplarily, at least one spray hole is arranged in a large number and evenly on the shower head 22, which can be distributed in a circle and expand layer by layer from the inside to the outside, and the spray head is a Teflon shower head. A spray switch 23 may also be provided on the liquid inlet pipe 2...

Embodiment 2

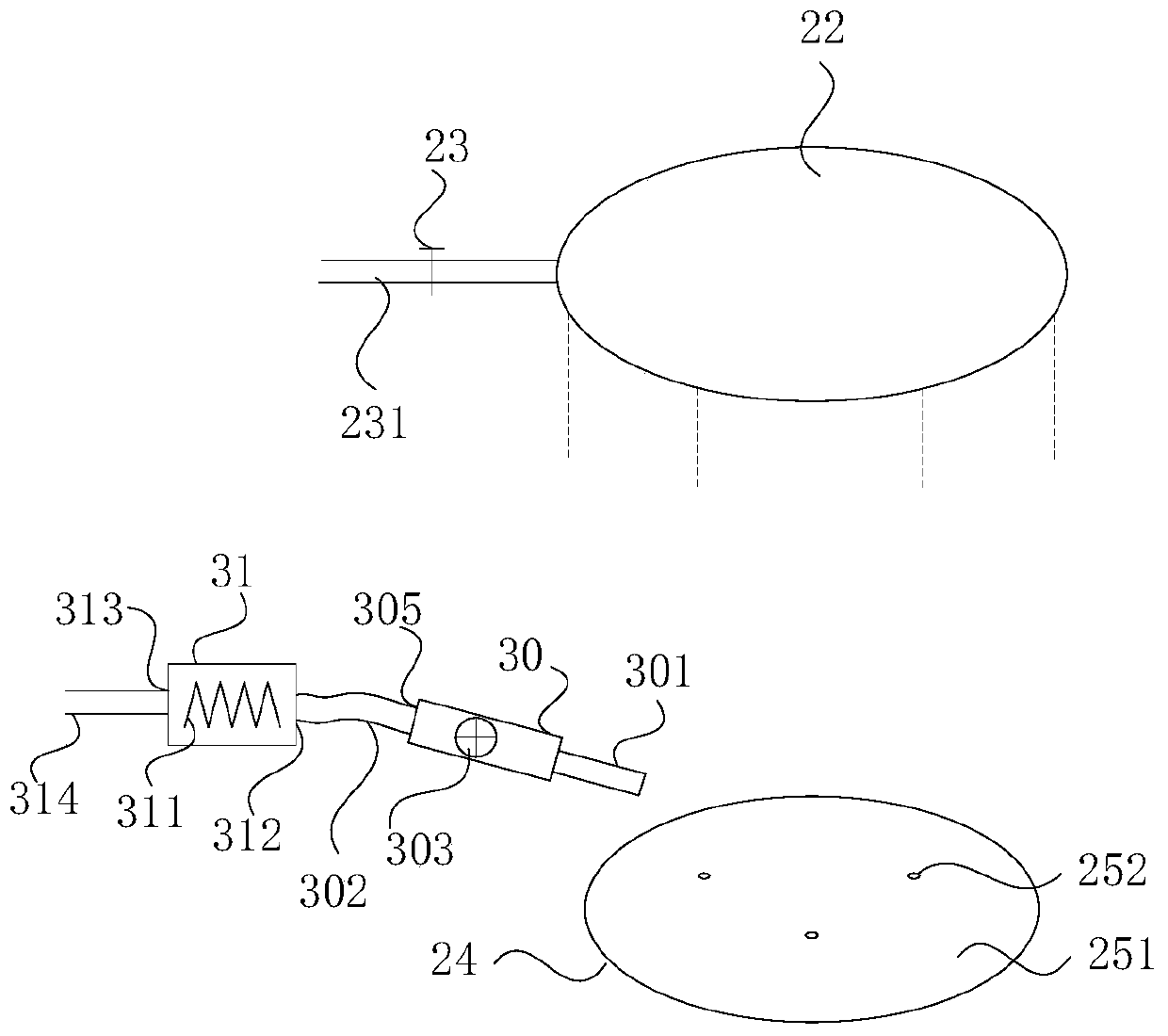

[0054] Figure 4 and Figure 5 A wafer drying device provided in Embodiment 1 of the present invention specifically includes: a liquid bucket 21, a spray head 22, a spray switch 23, a vacuum chuck 24, a vacuum pressure sensor 25, a vacuum pump 26, a vacuum valve 27, and a spray gun 30, and upper computer 28.

[0055] The liquid barrel 21 is used to hold the cleaning liquid, and the cleaning liquid is isopropyl alcohol (IPA).

[0056] The shower head 22 is provided with at least one spray hole, and the shower head 22 communicates with the liquid barrel 21 through the liquid inlet pipe 231 . Specifically, at least one spray hole is arranged in a large number and evenly on the shower head 22 , and can be distributed in a circle and expand layer by layer from the inside to the outside, and the spray head is a Teflon shower head 22 .

[0057] The spray switch 23 is arranged on the liquid inlet pipe 231, and is used to control the flow rate of the cleaning liquid. Specifically, ...

Embodiment 3

[0075] Figure 10 A wafer drying method provided in Embodiment 3 of the present invention. The wafer drying method in this embodiment can be controlled and executed by a host computer, including:

[0076] Step 202 , judging whether the wafer is fixed on the suction plate, and the suction plate includes at least one through hole.

[0077] In this embodiment, specifically, by detecting the vacuum pressure value of the through hole, and judging whether the wafer is fixed on the suction plate according to the vacuum pressure value;

[0078] In this embodiment, the vacuum pressure value of the through hole is detected by a vacuum pressure sensor disposed in the through hole of the vacuum chuck. In other embodiments, the vacuum pressure sensor can also be installed in the cavity of the vacuum chuck. Exemplarily, after the wafer is adsorbed on the carrier suction plate, the vacuum pressure sensor detects the vacuum pressure value of the through hole, and the host computer judges whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com